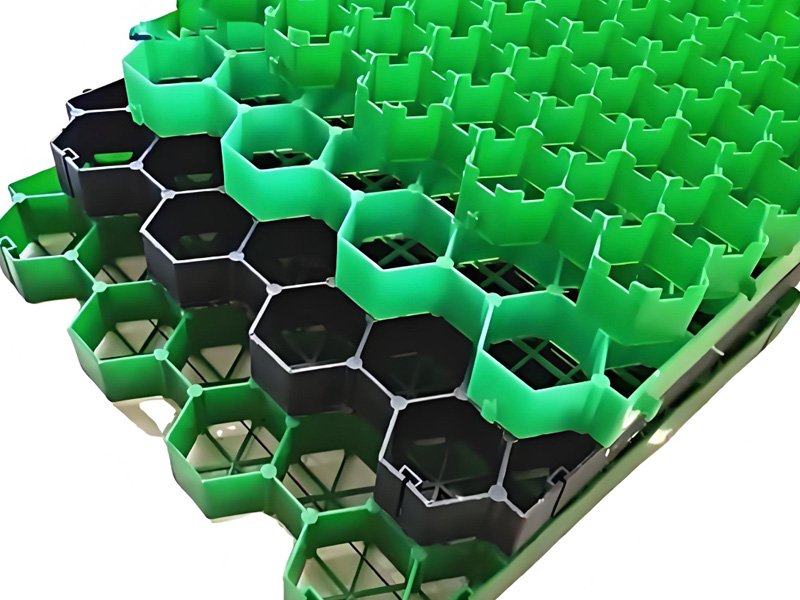

Plastic pavers are versatile solutions designed for parking, landscaping, and soil reinforcement in residential and commercial areas. Made from recyclable HDPE material, these pavers are suitable for use in various weather conditions and pH environments. With excellent stability and high compression strength, they can withstand heavy loads and are easily cuttable with saws for precise fitting. When filled with gravels, pebbles, or grass, BPM plastic pavers seamlessly adapt to available areas. Their permeable design enables natural water infiltration, preventing water accumulation and the risk of floods. Whether for driveways, walkways, or green spaces, BPM plastic pavers provide a reliable and customizable option for enhancing both functionality and aesthetics in outdoor areas.

1. What Are Plastic Pavers?

Plastic pavers, made from high-quality HDPE material, possess remarkable strength, wear resistance, anti-aging properties, and corrosion resistance. They are considered environmentally friendly materials, exhibiting higher grid density and greater tolerance compared to other brick pavers. Plastic pavers find extensive application in parking lots, fire engine access areas, exhibition centers, modern workshops, and roof gardens, among others.

BPM plastic pavers are designed to provide exceptional load-bearing strength while safeguarding the root systems of vegetation from harmful compaction. The pavers feature high void spaces within their cross-section, facilitating optimal root development and enabling efficient rainfall storage during storm events. For areas with prolonged usage and heavy loads, such as parking lots, selecting high-strength HDPE grass pavers is essential. Additionally, grid pavers are beneficial for locations exposed to long-term direct sunlight, such as open-air spaces, as they enhance soil thickness and improve water retention capacity.

BPM plastic pavers prioritize high stability to ensure reliable and long-lasting usage. They can withstand diverse climatic conditions and endure both acidic and alkaline environments. These qualities make BPM plastic pavers a dependable choice for various applications, offering durability, environmental sustainability, and adaptability to different settings.

2. What Are Advantages Of BPM HDPE Plastic pavers?

BPM HDPE plastic pavers are designed and manufactured with the advantages of reliable HDPE material, an interlocking system, high porosity, versatility in fill materials, strength, and cuttability. They also provide premium quality, customization options, enhanced stability, environmental sustainability, low maintenance requirements, and easy removal and reinstallation. These features make BPM HDPE plastic pavers an excellent choice for achieving functional, aesthetically pleasing, and sustainable outdoor surfaces.

1.2 Premium Quality

BPM (the specific manufacturer) ensures the use of high-quality HDPE material in their plastic pavers. This guarantees superior performance, longevity, and resistance to wear and tear.

2.2 Customizable Options

BPM HDPE plastic pavers come in various sizes, shapes, and colors, allowing for greater design flexibility and customization. This enables architects and designers to create unique and visually appealing patterns or configurations.

2.3 Enhanced Stability

BPM HDPE plastic pavers are designed with enhanced stability features, ensuring a secure and durable surface. They have excellent load-bearing capacity and can withstand heavy traffic without compromising their structural integrity.

2.4 Environmental Sustainability

BPM HDPE plastic pavers align with sustainable practices as they promote permeability, reduce stormwater runoff, and allow for the growth of vegetation. This contributes to ecological balance, reduces heat island effect, and supports a greener environment.

2.5 Low Maintenance

BPM HDPE plastic pavers require minimal maintenance. They are resistant to staining, cracking, and fading, reducing the need for frequent repairs or replacements. This results in long-term cost savings and hassle-free upkeep.

2.6 Easy Removal and Reinstallation

BPM HDPE plastic pavers can be easily removed and reinstalled, making them suitable for temporary installations or projects that may require changes in the future. This flexibility adds convenience and adaptability to evolving project needs.

3. Case Study of Plastic Pavers for Parking Lot in UK

In the UK, there was a case study where plastic pavers were utilized for a parking lot project. The objective was to increase the green area by incorporating lawns on the roadside and addressing soil compaction issues in various green spaces. Plastic pavers proved to be the ideal solution for these challenges. Furthermore, grass pavers were extensively employed in fire exits and parking lots to enhance green spaces and improve the overall ecological environment.

A customer from the UK contacted us with an inquiry regarding plastic pavers for their parking lot project. They specifically required products with high tensile strength and excellent load-bearing capacity. We provided them with a highly competitive price quotation, taking into account their specific needs. After careful consideration, they decided to proceed with our offer and signed both the supply contract and construction service agreement.

This case study highlights the effectiveness of plastic pavers in meeting the requirements of enhancing green spaces and addressing soil compaction issues in the UK. Our competitive pricing and commitment to delivering high-quality products and construction services played a pivotal role in securing the contract for the parking lot project. By choosing plastic pavers, our customer was able to achieve their goals of increasing green areas and improving the ecological environment while ensuring reliable and durable parking lot surfaces.

4. Specifications of Plastic Pavers for Parking Lot in UK

For the parking lot project in the UK, the plastic pavers used had the following specifications:

4.1 Plastic Paver Size

The plastic pavers measured 500mm × 500mm × 40mm. This size provided a suitable balance between stability and ease of installation.

4.2 Total Quantity of Plastic Pavers

A total area of 900m² was covered with plastic pavers. This quantity was determined based on the specific requirements and dimensions of the parking lot.

By utilizing plastic pavers with these specifications, the parking lot in the UK was able to benefit from their advantageous features. The size of the pavers allowed for efficient coverage of the designated area, while the 40mm thickness provided durability and load-bearing capability. The chosen quantity of 900m² ensured adequate coverage for the entire parking lot, accommodating the expected vehicular and pedestrian traffic.

Plastic pavers, with their specific size and total quantity, offered a practical and reliable solution for the parking lot project. These pavers provided a stable and environmentally friendly surface that addressed soil compaction issues while increasing the green space. The dimensions and quantity of the plastic pavers were carefully selected to meet the requirements of the project and to ensure the longevity and functionality of the parking lot in the UK.

5. About BPM Geosynthetics

BPM had been specializing in delivering one stop geosynthetics products and solutions to worldwide customers since its foundation in 2007. BPM Geosynthetics had provided many types of effective and state of the art geomembrane, geotextile, geocell, geosynthetic clay liners (GCLs), drainage board, geogrid to over 100 countries. If you have any questions or inquiries, please contact us, we will reply as soon as possible.