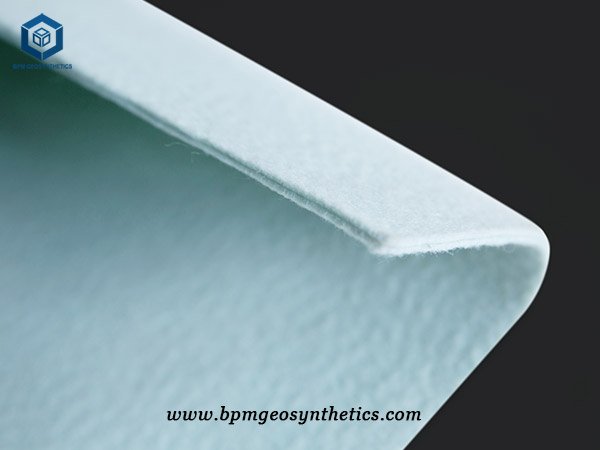

Composite geomembrane lining system, also known as composite geomembrane, is the kind of geosynthetic product combined of geotextile (base fabric can be filament or short fiber needle punched geotextile, woven geotextile) with geomembrane by heat bonding processing process. It remains the mechanical properties of base fabric and uniformity of geomembrane which improved the impermeability. Embossed processing on the geomembrane strengthens its friction coefficient, stability and easy for installation. Composite geomembrane lining system has the functions and advantages of both geotextiles and geomembranes. The geotextile layer increases essential tensile strength and the geomembrane layer provides excellent impermeable, leak and moisture proof, so the composite geomembrane lining system is a multi-function anti-leakage membrane liner with high tensile strength, reinforcement, separation, drainage, tear resistance, protection, etc.

1. Understanding Composite Geomembranes

Composite geomembranes are engineered materials that combine geomembranes with geotextiles to enhance performance. They are typically categorized into two types:

-

One Geotextile + One Geomembrane – Provides a balance of strength and impermeability.

-

Two Geotextiles + One Geomembrane – Offers superior puncture resistance and stability.

Key Features & Applications

-

Width: 4–6m | Weight: 400–2000g/m²

-

High tensile strength, slip resistance, and bursting strength for demanding civil engineering projects.

-

Heat-resistant due to polymer materials and anti-aging additives.

-

Widely used in:

-

Landfills & wastewater treatment (impermeable barrier)

-

Road construction & tunnels (reinforcement)

-

Aquaculture & agriculture (water retention)

-

Municipal & energy projects (durable lining)

-

2. Why Choose BPM Geosynthetics?

BPM Geosynthetics is a leading manufacturer and global supplier of high-quality geomembranes and geosynthetic products since 2010.

Our Product Range:

-

Geomembranes (HDPE, LDPE, LLDPE, PVC)

-

Geotextiles (woven & non-woven)

-

Geocells, GCLs, Geogrids, Drainage Boards

Quality Assurance:

✔ Certified by: ISO9001, ISO14001, SGS, Intertek, Soncap, SASO, BV

✔ Applications: Waste/water containment, mining, aquaculture, energy projects

Why BPM?

-

Custom solutions for all project sizes

-

Competitive wholesale pricing

-

Global supply & technical support

3. The Critical Role of Composite Geomembranes in Mining Operations

The mining industry generates vast amounts of solid waste, including ore, tailings, and waste rock, which often contain hazardous chemicals. To prevent environmental contamination, composite geomembrane lining systems are essential for:

-

Containing leachate from dissolved minerals in ore

-

Preventing leakage & corrosion of toxic waste materials

-

Collecting and refining chemical solutions for safe disposal

These lining systems must withstand moderate to high loads while resisting chemical degradation. BPM Geosynthetics is a proven supplier of high-performance composite geomembranes tailored for mining applications, ensuring durability and regulatory compliance.

4. Gécamines SA – Africa’s Mining Giant & Its Geomembrane Needs

Gécamines SA, the largest mining corporation in the Democratic Republic of Congo (DRC), specializes in copper and cobalt extraction. Key facts:

-

Operates in Katanga Province, home to the world’s largest cobalt reserves

-

Produced 500,000+ tons of copper annually in its peak

-

Partners with global firms like Glencore, Freeport-McMoRan, and Eurasian Natural Resources

Due to the scale of its operations, Gécamines requires ultra-durable composite geomembranes to:

✔ Contain acidic leachate from mining waste

✔ Prevent groundwater contamination

✔ Meet stringent environmental & safety standards

5. How BPM Delivered a High-Stakes Mining Solution for Gécamines SA

5.1 Project Timeline & Success Factors

-

Initial Contact (Feb 6, 2019):

-

Gécamines found BPM via Google search and submitted specifications.

-

Their engineers visited BPM’s factory to inspect manufacturing quality.

-

-

Urgent Order & Compliance:

-

50,000 sqm composite geomembrane with BV Certification (Bureau Veritas).

-

10 containers of HDPE pipes for auxiliary infrastructure.

-

Full payment secured within 7 days due to BPM’s reliability.

-

-

Quality Assurance & Delivery:

-

All materials passed third-party BV anchor trench tests.

-

Completed shipment within 2 weeks, meeting strict deadlines.

-

5.2 Specifications of Composite Geomembrane Lining System for Mining Project in Congo

- Total quantity – 50,000 square meters

- Specification – two layer 300g/㎡ nonwoven geotextile+ one layer 1.5mm geomembrane

- Each roll size – 5.8m*50m

- Rolls – 173

- Inspected by BV

6. Considerations for Composite Geomembrane Installion

6.1 Base Preparation & Geomembrane Installation

Proper base preparation is critical for composite geomembrane performance. First, level the surface with fine sand or small-diameter clay. Lay the geomembrane without overstretching, allowing slight waves for flexibility. Cover it with a 10cm layer of sand/clay, then add a 20-30cm block stone protection layer to prevent punctures. Avoid direct stone-to-membrane contact. Anchor edges using expansion bolts and steel strips, sealing joints with 2mm emulsified asphalt for leak prevention.

6.2 Surface Protection & Seam Integrity

Ensure the supporting surface is smooth to avoid geomembrane punctures. Use fine-grain cushioning if needed. Minimize seams in corners or slopes steeper than 1:6. For connections, use bonding, welding, or vulcanization based on material type. HDPE liners require welding machines for secure seams. All joints must undergo impermeability testing to prevent leaks.

6.3 Boundary Anchoring & Transition Layers

Secure the geomembrane to surrounding structures via anchor trenches. For shallow gravel bases, excavate to bedrock and embed the liner in concrete. For impermeable bases, use 2m-deep trenches with clay backfill. In deep gravel layers, apply HDPE geomembrane coatings. Include a 30cm transition layer (max 20mm grain size) and a protective filter layer. PVC/rubber liners can adhere directly, while HDPE requires ≥0.8m concrete embedding.

6.4 Post-Installation Care & BPM’s Expertise

Limit foot traffic and heavy tools on installed geomembranes. When stacking mining ore, follow safety protocols to avoid damage. BPM has supplied millions of square meters of geomembranes to Africa/South America, meeting strict mining standards like GAI LAP and third-party testing. We offer design, installation, and high-quality compliance for global mining projects.

About BPM

BPM have provided many types of effective and state of the art geomembrane, geotextile and geosynthetics products to over 36 countries. Our main innovative, high quality geosynthetics products include geomembrane, geotextiles, geocell, geosynthetic clay liners (GCLs), drainage boards, geogrids, etc. BPM brand brand high quality geosynthetic products had been certificated by the ISO9001, ISO14001,OHSAS18001 Soncap, SASO and BV, SGS and Intertek, etc.

BPM is also providing professional design and installation service. OEM and ODM are also available. If you have any questions or inquiries, please fill and submit the following form, we will reply as soon as possible.