Geogrid and geotextile fabric are both types of geosynthetic materials used in various civil and environmental engineering applications. In this article, we will compare geogrid vs geotextile to tell you everything you need to know:

BPM Geosynthetics is the leading geosynthetics manufacturer and supplier, we offer a wide range of geogrid and geotextile fabric with 0.5 to 3mm (20mils to 120 mils) thickness at best factory price.

1. What is Geogrid?

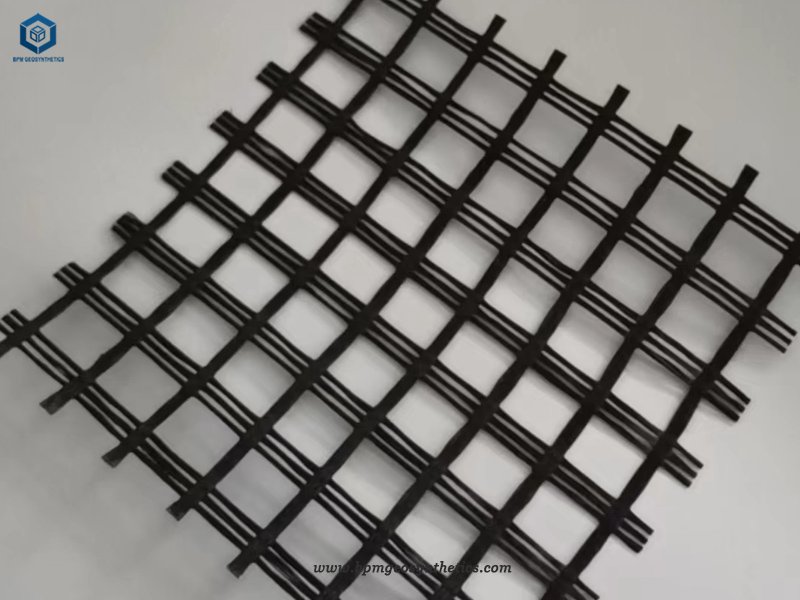

Geogrid is a synthetic material used to reinforce soil and is made of high molecular polymer. It has a mesh structure that can increase the bearing capacity and shear strength of the soil, providing additional support and making the foundation stronger and more stable. Geogrid has the advantages of excellent water permeability, strong durability, and long service life.There are mainly the following types of geogrids on the market now:

1.1 Uniaxial Geogrid

BPM Uniaxial Geogrid is made of high molecular polymer after extruded and laminated and punched into regular mesh before longitudinal stretching. It has large tensile strength(>150Mpa), Applied to all kinds if soft foundation reinforcement treatment,enchance improve roadbed subgrade bearing capacity and retaining walls under long-trem stress state

1.2 Biaxial Geogrid

Biaxial Geogrid on the longitudinal and transverse has great tensile strength. This kind of structure in the soil can also provide a more effectively undertake the chain and the spread of the thought system. Make reinforcement treatment for various kinds of soft soil foundation to evenly distribute load stress and reduce un-even settlement

1.3 Fiberglass Geogrid

BPM Fiberglass Geogrid make full of yarn strength in textile, improve its chemical performance, make it have good tension resistance, tear resistance and creep resistance and is formed by excellent modified asphalt coating treatment. Strengthen bitumen concrete roadway, reduce any prevent various kinds of reflection gaps on roadway

1.4 Warp Knitting Polyester Geogrid

BPM Warp Knitting Polyester Geogrid is a type of geogrid that utilizes a warp knitting oriented structure. This structure involves the intersection of textile fiber filament bundles, creating a reliable combining site that exhibits excellent mechanical properties.

The warp knitting process used in the production of this geogrid ensures a high degree of dimensional stability and strength. The textile fiber filament bundles are tightly intertwined, resulting in a grid-like structure with strong interlocking points. This design enhances the geogrid’s ability to distribute and withstand loads, improving its mechanical performance.

2. What Is Geotextile Fabric?

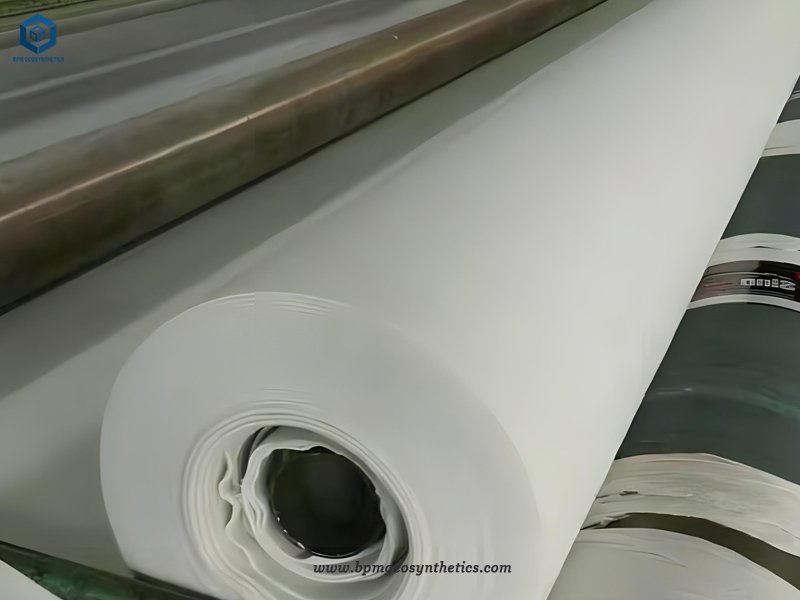

Geotextile is a geosynthetic material produced from synthetic fibers through a needle punching or weaving process. It is in the shape of cloth and has good functions of filtering, absorbing water, isolating and enhancing safety. Geotextile has the characteristics of light texture, high toughness and strength, good permeability, high temperature resistance, freeze resistance, aging resistance, corrosion resistance, etc., so it is widely used in various geotechnical projects.

Geotextiles are divided into woven geotextiles and non-woven geotextiles. Non-woven geotextiles are divided into staple fiber needle punched geotextile and filaments polyester geotextile. allowing simultaneous separation and filtration. Non-woven geotextiles combine the strength of woven fabrics with high permeability, making them a better choice when applications require both separation and filtration.

Woven geotextiles can be categorized into two main types: PP woven geotextiles and PET woven geotextiles. These geotextiles are constructed using two sets of parallel threads or yarns. They possess a combination of high strength and low permeability, making them highly effective in bridging over wet or inferior soil layers.

PP woven geotextiles are made from polypropylene threads or yarns that are woven together. They exhibit excellent tensile strength, allowing them to withstand heavy loads and provide reinforcement to the soil. These geotextiles also have low permeability, which means they restrict the flow of water through the fabric. This characteristic is beneficial in applications where water needs to be controlled or redirected, such as in erosion control or drainage systems.

PET woven geotextiles, on the other hand, are manufactured using polyester threads or yarns. Similar to PP woven geotextiles, they offer high strength and low permeability. The polyester material provides superior resistance to UV radiation and chemical degradation, making PET woven geotextiles more durable and suitable for long-term applications. They are commonly used in reinforcement applications where stability and longevity are crucial, such as in road construction or landfill liners.

The high strength of woven geotextiles enables them to bridge over weak or unstable soil layers. They distribute loads effectively, reducing the risk of soil settlement and improving overall stability. By providing a stable platform, these geotextiles help prevent differential settlement and maintain the integrity of the structure built on top.

3. What is The Difference of Geogrid VS Geotextile Fabric?

Geotextiles and geogrids are two types of geosynthetic materials that serve different purposes in civil engineering and construction projects. Geotextiles are primarily designed for separation, filtration, and drainage, while geogrids are specifically manufactured as reinforcement materials. Here are the key differences between geotextiles and geogrids:

3.1 Different Purpose

Geotextiles are primarily used for separation, filtration, and drainage functions. They are employed to manage water flow, prevent soil erosion, and stabilize foundations. Geotextiles act as a barrier between different soil layers, preventing their mixing and maintaining the integrity of each layer. On the other hand, geogrids are specifically designed to enhance the load-bearing capacity and shear strength of soil. They reinforce the soil structure and prevent erosion and slides.

3.2 Different Applications

Geotextiles are extensively used in water conservancy projects, such as river management, reservoir construction, and coastal protection. They help with sediment control, shoreline stabilization, and filtration in these applications. Geotextiles are also utilized for foundation reinforcement and stabilization, providing efficient drainage and preventing the buildup of excess water. Geogrids, however, find applications in road construction, railway systems, and building foundations. They enhance the structural integrity and stability of these projects, ensuring the soil can bear heavy loads and reducing the risk of soil movement.

3.3 Different Functions

Geotextiles primarily function to separate different soil layers and prevent their intermixing. By acting as a filtration layer, geotextiles allow water to pass through while retaining soil particles, preventing clogging and maintaining efficient drainage. Geogrids, with their unique interlocking grid structure, reinforce the soil and improve its load-bearing capacity. They distribute loads more evenly, reducing stress concentrations and preventing the movement of soil particles.

3.4 Different Installation Process

The installation process for geotextiles involves cleaning the ground surface, accurately measuring and determining the laying range, unfolding and fixing the geotextile in place, conducting inspections and acceptance checks, and finally laying a protective layer on top. Geogrid installation includes steps such as cleaning and filling joints and cracks, washing the road surface to ensure proper adhesion, laying the geogrid tightly and straight, fixing it using iron nails or wooden wedges, and promptly filling the filler material.

4. Summary

Geotextiles and geogrids serve distinct purposes in civil engineering projects. Geotextiles focus on separation, filtration, and drainage, while geogrids are designed for soil reinforcement and increased load-bearing capacity. Understanding these differences is crucial for selecting the appropriate material to ensure desired project performance and longevity.

Geotextiles primarily reinforce foundations, prevent soil erosion, enhance soil stability, and provide filtration, drainage, and protection. They find applications in various projects, including water conservancy, where they play a vital role in managing water flow and stabilizing the soil.

Geogrids, on the other hand, are primarily used to improve soil bearing capacity and reduce deformation. They are widely employed in highways, railways, water conservancy, and other engineering fields. Geogrids are particularly effective in preventing pavement cracking and improving roadbed stability.

By recognizing these distinctions, engineers and construction professionals can make informed decisions and select the appropriate geosynthetic material for their specific construction needs. This ensures optimal performance and longevity of the project while addressing the unique requirements of the site.