Geogrid and geocell are geosynthetic materials integral to civil engineering and construction. However, geogrid vs geocell, but what is different purposes and distinct characteristics they have. Geogrid, a mesh of synthetic polymers or metals, strengthens soil by distributing loads, applied in retaining walls and slope stabilization. In contrast, geocell, a 3D cellular system, creates stable foundations for projects like roadways and embankments.

BPM is the leading geosynthetics manufacturer and supplier, we wholesale complete line of geocells and geogrids for worldwide customers. From the geosynthetics manufacturer’s view, the differences of geogrid vs geocell lie in material composition, installation methods, and overall performance. Evaluating these factors is vital for informed material selection. We hope this article with help you to choose the right geosynthetic material for your specific projects.

1 What is Geogrid

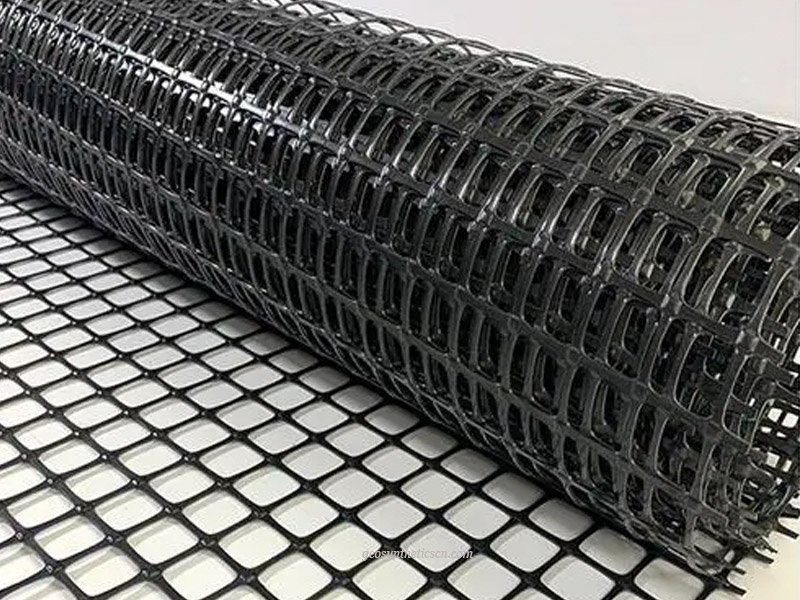

Geogrid is a crucial geosynthetic material meant to improve the stability and strength of soil-based structures. Due to its unique grid-like design, geogrids are crafted from resilient polymers positioned strategically for reinforcement. The primary objective of geogrid is to infuse tensile strength into soil, curbing the risks of lateral movements while enhancing overall structural cohesion. This versatile material has found its place in a range of civil engineering and construction endeavors, making significant contributions to soil stabilization and reinforcement efforts. BPM Geosynthetics offers a diverse range of geogrids with various material options to cater to your specific needs. Whether you require geogrids with high strength and excellent tensile performance or products with corrosion resistance for specific environmental conditions, we have suitable solutions for you.

BPM geogrids generally categorized into plastic geogrid, fiberglass geogrid, warp knitting polyester geogrid, steel plastic geogrid mesh, etc

2 What is A Geocell

Geocell, distinguished by its three-dimensional honeycomb-like structure, is an ingenious geosynthetic solution. Typically crafted from materials like high-density polyethylene, geocells occupy a pivotal position in soil confinement, erosion prevention, and efficient load distribution. The singular design of geocells enables their utilization in a range of applications, including slope protection, retaining walls, and other soil stabilization endeavors. With its exceptional ability to provide structural support and curtail soil erosion, geocell technology continues to be a treasured asset in modern civil engineering and construction practices. BPM HDPE Geocell finds extensive application in construction, serving purposes such as base stabilization, slope erosion control, flat ground soil stabilization, shoreline protection, multi-layered retaining walls, channel fortification, and structural reinforcement for robust load-supporting roads and earth retention projects.

3 What Similarities Exist Between Geogrid and Geocell?

3.1 Reliable and Efficient Engineering Materials for a Range of Geotechnical Applications

Polymer composite materials exhibit outstanding properties, including exceptional strength, robust load-bearing capacity, minimal deformation, low creep, corrosion resistance, substantial friction coefficient, prolonged lifespan, and convenient, rapid construction. These materials are widely used in a range of fields such as highway and railway construction, bridge abutments, approach structures, wharves, dams, slag fields, and soft soil foundation reinforcement. Due to their advantageous characteristics, they are also employed in retaining wall construction and pavement crack engineering. BPM Geosynthetics assures the use of premium-quality raw materials, all of which undergo rigorous testing and hold various specialized certifications to meet the highest standards.

3.2 Multi-Purpose Geotechnical Materials for a Variety of Engineering Projects

Geogrid and Geocell possess a wide range of applicable engineering projects. Geogrid vs geocell can be effectively utilized in various projects, including soil reinforcement, retaining wall construction, bridge foundation support, embankment stabilization, and erosion control measures. The extensive application scope of these materials facilitates their adaptability to various geo-environmental conditions. Additionally, due to their exceptional performance, they are frequently employed in critical infrastructure projects, including dams, levees, and highways. Furthermore, they are also used in environmental remediation projects, such as slope stabilization and soil erosion control. The adaptability and flexibility of these materials facilitate their usage in various geo-environmental conditions, making them a preferred choice for geotechnical engineers.

3.3 Customization Options

Geogrid and Geocell offer the flexibility to be customized based on specific engineering requirements. This adaptability allows them to be tailored for various projects, ensuring optimal performance and meeting specific design criteria. The customization process involves selecting the appropriate material type, mesh size, thickness, and other properties according to the application. By customizing Geogrid and Geocell, engineers can create solutions that address the unique challenges of each project, resulting in cost-effective and efficient designs. This versatility and adaptability further enhance their effectiveness across different geo-environmental conditions.

3.4 Environmental Friendliness

Geogrid and Geocell share a strong commitment to environmental sustainability. Their manufacturing process does not involve the use of harmful chemicals or solvents, making them environmentally benign. Additionally, these materials are derived from recyclable raw materials, reducing the demand for non-renewable resources. Their use in construction projects helps to promote a circular economy and reduce the carbon footprint of engineering activities.

Moreover, Geogrid and Geocell can be easily recycled at the end of their lifespan. This ability to be reused or repurposed extends their useful life and reduces the amount of waste sent to landfills. By employing these environmentally friendly materials, engineers can contribute to the development of sustainable infrastructure while minimizing the impact on the environment.

The environmental-friendly attributes of geogrid and geocell align with the growing emphasis on sustainable development and contribute to the transition towards a greener civil engineering practice.

4 What is The Difference of Geogrid vs Geocell

4.1 Material Composition

Geotextiles are manufactured for separation, filtration, and drainage purposes. They allow the free movement of water from the soil into the aggregate layer and vice versa, while maintaining their thickness, service life, and long-term strength. Geotextiles function as frictional resistance dependent reinforcement, providing separation and maintaining stability.

Geogrids are specifically manufactured as a reinforcement material. They interlock with the soil, providing passive resistance and enhancing stability. Geogrids are made of either synthetic polymers or metals, such as polypropylene, polyester, polyethylene, steel, or aluminum. The choice of material depends on the specific project requirements and desired performance. Geogrids offer high tensile strength, durability, and resistance to deformation.

4.2 Different Application of Geogrid vs Geocell

Geotextiles are commonly used for separation, filtration, and drainage purposes. They are suitable for applications including grading, evacuation, vegetation allowance, and placement directly on prepared subgrade. Geotextiles function to maintain stability, prevent soil movement, and facilitate water movement between soil and aggregate layers.

Geogrids are primarily used as reinforcement material in various civil engineering applications. They are commonly employed in retaining walls, road construction, and slope stabilization projects. Geogrid installation involves planning the retaining wall, sub-base and base stabilization, gravel leveling, and laying retaining wall blocks. Geogrids enhance stability, increase load-bearing capacity, and prevent soil erosion.

4.3 Different Functions

Geotextiles provide separation, filtration, and drainage functions. They allow the free movement of water between soil and aggregate layers, ensuring proper drainage and preventing soil movement. Geotextiles function as frictional resistance dependent reinforcement, maintaining stability and preventing the loss of aggregate materials.

Geogrids act as reinforcement material, enhancing soil strength and stability. They interlock with the soil, providing passive resistance and increasing load-bearing capacity. Geogrids prevent lateral spreading, maintain the integrity of structures, and improve overall stability.

4.4 Different Performance Factors

Geotextile: Geotextiles offer several performance advantages. They provide separation, filtration, and drainage functions, ensuring proper water movement and preventing soil movement. Geotextiles maintain their thickness, service life, and long-term strength. They are resistant to deformation and provide stability for civil engineering structures.

Geogrid: Geogrids offer high tensile strength, durability, and resistance to deformation. They enhance soil stability, increase load-bearing capacity, and prevent soil erosion. Geogrids provide long-term performance and stability for civil engineering projects.

5 Conclusion

Geogrid and geocell are two important geosynthetic materials used in civil engineering. Geogrid vs geocell has distinct functions. Geogrids, made from synthetic polymers or metals, are used to enhance soil stability in applications such as retaining walls and road construction. In contrast, geocells, which feature a three-dimensional cellular structure, are employed to establish stable foundations in projects such as roadways and embankments. Both materials share robust characteristics including strength, bearing capacity, minimal deformation, and corrosion resistance, making them suitable for a range of projects. They are also customizable and environmentally friendly, representing sustainable choices in the evolving field of civil engineering. Understanding the subtle differences between them is crucial for optimal material selection in geotechnical applications.