Geocell and geogrid are both geosynthetic materials used in civil engineering and construction for soil stabilization, erosion control, and reinforcement purposes. While they share some similarities, they also have distinct differences in terms of design, application, and performance. Choosing geogrid vs geocell requires comprehensive consideration based on specific engineering needs and actual conditions. Let’s delve deeper into a more comprehensive comparison between geocells and geogrids, considering various factors.

1. What Is A Geocell?

A Geocell is a mesh cell structure formed by strong welding or riveting of high-strength HDPE or PP copolymer strips. It is made of modified polyethylene as raw material, extruded and cut into polymer strips, and then connected to each other through ultrasonic welding. This material has a three-dimensional mesh or honeycomb structure, which is flexible andcan be folded during transportation and stretched to form a planar body with a mesh structure during use.

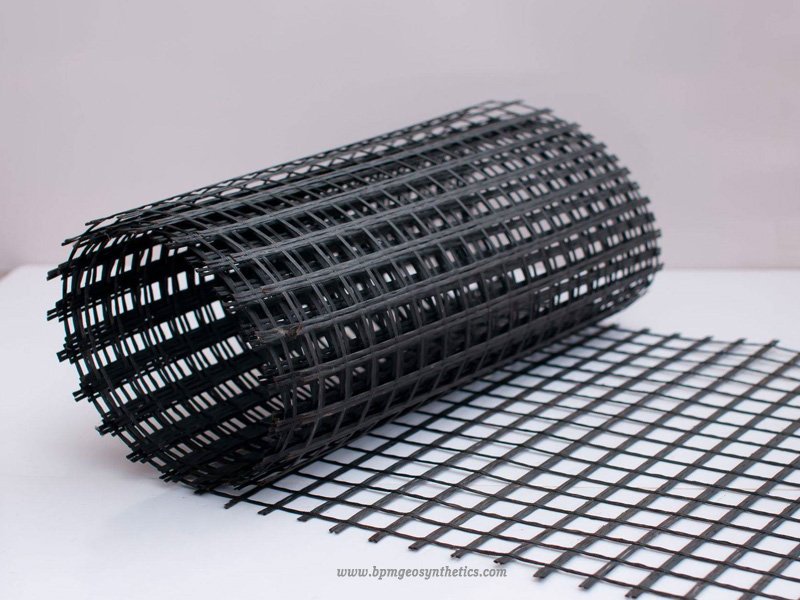

2. What Is A Geogrid?

Geogrid is a major geosynthetic material. Compared with other geosynthetic materials, it has unique performance and efficacy. It is a two-dimensional mesh screen or a three-dimensional mesh screen with a certain height made of polypropylene, polyvinyl chloride and other high molecular polymers that are thermoplastic or molded.Geogrids are divided into four categories: plastic geogrids, steel-plastic geogrids, fiberglass geogrids and polyester warp-knitted polyester geogrids.

3. What are the Similarities Between Geocell And Geogrid?

3.1 Polymer Composite Materials

Geocells and geogrids are made of polymer composite materials. These materials have the characteristics of high strength, load-bearing capacity, small deformation, small creep, corrosion resistance, large friction coefficient, long service life, and convenient and quick construction.

3.2 Enhance Foundation Stability

Both geocells and geogrids can be used to enhance foundation stability. They can effectively improve the bearing capacity of the foundation, reduce the lateral displacement and deformation of the soil, and prevent problems such as foundationsettlement and landslides.

3.3 Dispersed Loads

Both geocells and geogrids can be used to disperse loads. They can spread larger concentrated loads over a larger area,

reducing pressure on local soil, thereby avoiding problems such as soil damage and foundation settlement.

3.4 Good durability

Both geocells and geogrids have good durability and can be used for a long time under harsh environmental conditions and have a long service life.

3.5 Environmentally friendly and sustainable

Geocells and geogrids are environmentally friendly and sustainable materials that can be recycled and reused without causing a negative impact on the environment.

4. What Are The Differences of Geocell vs Geogrid?

There are significant differences between geogrid vs geocell in the following aspects:

4.1 Shape and structure

Geogrid is a two-dimensional grid or a three-dimensional grid screen structure with a certain height, while geocell is a three-dimensional mesh cell structure formed by welding reinforced HDPE sheet materials.

4.2 Mechanical properties

In terms of mechanical properties, the geocell is stiffened in three dimensions, while the geocell is stiffened in plane. Specifically, the lateral limits and stiffness of the geogrid are better than that of the geogrid, and they are also better than the geogrid in terms of bearing capacity and distributed loads, in addition, the anti-sliding and anti-deformation ability of the geogrid is also better than that of the geogrid.

4.3 Application Fields

Both are widely used in a series of soft foundation treatment such as road infrastructure construction, foundation reinforcement, retaining wall and ground anti-cracking fiber engineering projects. However, the emphasis is different, the geoglage is mainly used to strengthen the stability and bearing capacity of the soil, and forms an integrated structure with the soil by burying, embedding or laying in the soil to enhance the tensile strength, shear strength and compressive strength of the soil. The function of geoglage chamber is to provide a soil and water conservation measure to prevent soil erosion and maintain soil stability. By laying on slopes, rivers, reservoirs, farmland, urban landscaping and other places, a surface protection layer with good water permeability and water retention is formed.

4.4 Economic Cost

The cost of geogrid is relatively low, while the cost of geocell is slightly higher, but its excellent mechanical properties and stability make it more economical in long-term use.

5. Table of of Geocell vs Geogrid

| NO | Item | Geocell | Geogrid |

|---|---|---|---|

| 1 | Structure | Three-dimensional, honeycomb-like structure. Interconnected cells made of high-density polyethylene (HDPE) or other polymeric materials. | Flat or grid-like sheets made of polymers, fiberglass, or other materials. Can be uniaxial or biaxial, indicating reinforcement in one or both directions. |

| 2 | Application | Geocells are primarily used for soil stabilization, slope protection, load support, and erosion control. Common applications include retaining walls, road construction, and channel lining. | Geogrids are used for soil reinforcement in applications such as retaining walls, embankments, and pavements. They are commonly employed to enhance the tensile strength of soils. |

| 3 | Functionality | The geocells are filled with soil, aggregate, or other infill materials, creating a confined and stable structure. Geocells distribute loads laterally, reducing pressure on the underlying soil and providing reinforcement. | Geogrids work by reinforcing soil and preventing horizontal movement, enhancing the soil’s stability and load-bearing capacity. They are often installed between soil layers to distribute loads and reduce settlement. |

| 4 | Flexibility | Geocells are highly flexible and can conform to various terrains and surface irregularities. They are suitable for both soft soil and steep slope applications. | Geogrids are generally less flexible than geocells and may require additional components for conforming to irregular surfaces. |

| 5 | Load Distribution | Distribute loads laterally, reducing vertical pressure on the soil. Ideal for load support and slope protection. | Distribute loads horizontally, reinforcing soil. Enhance tensile strength to prevent soil movement. |

| 6 | Installation | Relatively easy to transport and install. Suitable for irregular terrains. | Installation may require careful consideration, especially on uneven surfaces. Connection and anchoring methods vary based on project requirements. |

| 7 | Material | Typically made from HDPE or other polymeric materials. Resistant to environmental conditions and chemical degradation. | Made from polymers, fiberglass, or other materials. Material selection depends on factors like strength requirements and environmental conditions. |

| 8 | Cost | Costs may vary based on the material, cell size, and project specifications. Generally, costs are competitive compared to alternative solutions. | Costs depend on material, strength specifications, and project requirements. Can be cost-effective for soil reinforcement applications. |

6. Summary

Through comparison, we can understand the differences between geogrids and geocells in terms of structure and form, application fields, mechanical properties and economic costs.

When it is necessary to improve the load-bearing capacity and stability of the foundation, especially in the case of soft soil foundations, geocells are a good choice. It can reduce the intensity of construction operations, speed up construction, and has better performance and lower project costs. Geocells are also a good choice when it is necessary to prevent landslides and reduce lateral soil displacement and deformation. It provides better lateral restraint and stiffness, thereby increasing the stability of the foundation.

In projects where embankment reinforcement is required, geogrids may be more suitable. It has strong tensile propertiesand extensibility and can withstand large tensile stress.Geogrids are also a good choice when load distribution is required.It can spread larger concentrated loads over a larger area and reduce pressure on local soil.

At BPM Geosynthetics, we supply high quality geocell and geocell at great factory price.

Any questions or inquiries, please contact us.