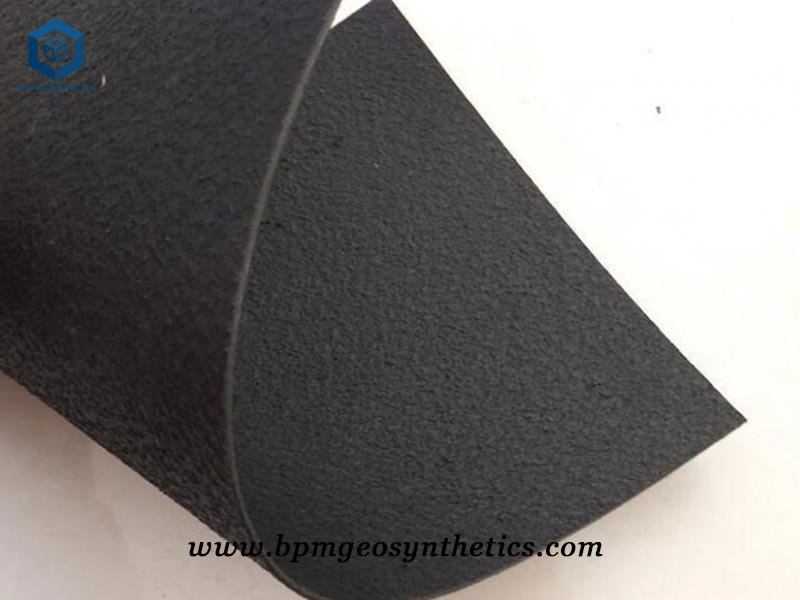

The textured HDPE sheet, also called textured geomembrane, is designed and fabricated with either single-sided or double-sided textured surface. Textured HDPE geomembrane has a rough surface which can highly improve the friction coefficient which fits more suitable for steep slope and vertical engineering design work which maximize the effective volume of geomembrane. BPM brand textured HDPE sheet has excellent temperature adaptability, weldability, weather resistance and good aging resistance, chemical resistance, environmental stress crack resistance and puncture resistance. Therefore, the textured HDPE sheet is especially suitable for underground engineering, mining engineering, landfills, sewage or waste disposal sites as anti-leakage materials.

For the textured geomembrane: the flat extrusion process is a two-step forming method. After the smooth geomembrane is produced, the rough surface is formed on the smooth surface by spraying the coarse particles. The finished textured HDPE sheet product is not a whole material, and the rough spots are easily peeled off to greatly increase the possibility of landslide accidents, the consequences are unimaginable.

BPM adopts the blown film process as a one-step forming method. During the production, the textured geomembrane rough surface is formed by adding nitrogen gas, and the finished product is a whole, and the rough spots are not easy to peel off. Moreover, the various values of the original geomembrane will not be changed.

The textured HDPE geomembrane has a large friction coefficient and strong anti-skid function, and is more suitable for steep slope and vertical anti-seepage, and improves engineering stability. The use of textured geomembrane in these areas is to enhance the friction between the textured geomembrane and the slope to prevent slippage. However, if the textured HDPE sheet is used improperly or if you do not pay attention to the things you should pay attention to, you may not achieve the above effects.

Four Key Points on How to Install Textured HDPE Sheet

First, pay attention to the seams between two textured geomembranes. When laying textured geomembrane, it will definitely encounter the problem of joints, because there is a need for joint between the two textured geomembranes. Under normal circumstances, the joints of textured geomembrane are hot welded, which have very good effect. Secondly, special glue bonding can also be used, but this method is more firmly bonded without the hot melt welding technique.

Second, install the textured HDPE sheet in the right way. When installing, the textured geomembrane should be spread out along the principle of one direction, and the textured geomembrane of each unit should be adjusted to meet the specification requirements, which is beneficial to the subsequent welding work. After the paving, it should be pressed with a sandbag to prevent it from being blown by the wind, and to ensure that the seams at the edges are sufficiently dry and clean.

Third, the right welding operation. The key to weld the textured geomembrane is to ensure that the HDPE textured sheet is sufficiently flat and free of wrinkles, so adjust it in advance. And when welding, you should find professional and experienced technical personnel to operate, not only to adjust the machine temperature and speed, but also need certain professional skills.

Fourth, pay attention to the impact of the environment. Different environments will achieve different effects. When constructing the textured geomembrane, strictly observe the operation process, pay attention to different environments, and adjust the site environment at any time to achieve better laying effect.

About BPM

BPM have provided many types of effective and state of the art geomembrane, geotextile and geosynthetics products to over 36 countries. Our main innovative, high quality geosynthetics products include geomembrane, geotextiles, geocell, geosynthetic clay liners (GCLs), drainage boards, geogrids, etc. BPM brand PET geosynthetics had been certificated by the ISO9001, ISO14001,OHSAS18001 Soncap, SASO and BV certificates and passed the test of SGS and Intertek, etc.

BPM is also providing professional design and installation service. OEM and ODM are also available. If you have any questions or inquiries, please fill and submit the following form, we will reply as soon as possible.