1. What Is A Plastic Tank Liner?

A plastic tank liner, also knwon as geomembrane liner, serves as a crucial lining material that creates a protective barrier within plastic or other tanks and containers. Its primary purpose is to prevent direct contact between the stored contents and the tank material, safeguarding against corrosion, chemical degradation, and contamination. These liners are typically constructed from flexible plastics like polyethylene (PE) or polyvinyl chloride (PVC).

Each liner is custom-fabricated to fit the precise dimensions and shape of the tank, ensuring a secure and accurate installation. Plastic tank liners find widespread use across diverse industries, including water and wastewater treatment, chemical processing, food and beverage, pharmaceuticals, and agriculture. By employing plastic tank liners, businesses can effectively extend the lifespan of their tanks, reduce maintenance costs, and uphold the integrity and quality of stored liquids or substances. These liners offer an efficient and practical solution for preserving the structural integrity of tanks, while also safeguarding the purity and safety of the stored materials.

2. Why Choose Plastic Tank Liner Philippines for Shrimp Tank?

Custom plastic tank liners, specifically HDPE tank liners, are made from high-quality polyethylene virgin resin. These liners are enhanced with additives such as carbon black, anti-aging agents, anti-ultraviolet absorbers, and stabilizers. This combination of materials creates an effective waterproof and barrier engineering material.

When compared to traditional materials, plastic tank liners offer numerous benefits. Traditional materials often come with high costs, short service cycles, and limited economic benefits, which can hinder the rapid development of aquaculture. In contrast, plastic tank liners provide a cost-effective and durable solution that promotes the growth of the industry.

Aquaculture has seen rapid development in the Philippines since its emergence in the 1920s. It has become a significant activity in the country, aimed at improving local production, ensuring food security, and increasing export income. By choosing plastic tank liners, shrimp farmers can create a controlled environment that helps optimize shrimp growth and health. These liners effectively prevent leaks, protect against corrosion and contamination, and facilitate easy maintenance.

Furthermore, plastic tank liners offer flexibility in terms of customization. They can be tailored to fit the specific dimensions and requirements of shrimp tanks, ensuring a precise and secure fit. This customization contributes to the efficient use of space and resources in aquaculture operations.

Choosing for plastic tank liners in the Philippines for shrimp tanks provides cost-effectiveness, durability, and customization options. These liners support the growth and sustainability of the aquaculture industry by offering reliable waterproofing and barrier solutions.

3. Solution of Custom Plastic Tank Liner for Shrimp Tank in Philippines

A customer from Malaysia discovered BPM through our website and inquired about the quantity and price of a custom plastic tank liner for their shrimp tank. The tank had a diameter of 30 meters and a height of 2 meters. We provided professional advice based on the specific requirements of the project. After conducting a local investigation and comparing multiple options, the customer agreed with our recommendation of a 1.0 mm HDPE tank liner.

We promptly provided the customer with a quotation and sent samples of the product. The customer expressed satisfaction with both the price and the quality of the samples. As a result, they decided to place an order for the 1.0 mm custom plastic tank liner due to its excellent cost-performance ratio. Additionally, the customer purchased a welding machine to facilitate the installation process.

This successful transaction showcases the customer’s confidence in BPM’s expertise and product offerings. We are committed to delivering high-quality plastic tank liners and providing comprehensive support to our customers throughout their projects.

4. What Are Benifits of Custom Plastic Tank Liner for Shrimp Tank in Philippines

(1)High intensity. The tensile strength of thick rubber pond liner can reach 18MPa, the tensile strength at break can reach 35MPa, the peel strength is 31kN/m, the shear strength is 33kN/m, and the ductility is good. The elongation at yield is 13% to 16%, and the elongation at break is 700% to 800%. It has good surface compliance and weather resistance. When it really fails, the strain is about 1000%.and especially for a round fish tank, the ground and sides need to bear the pressure alone. This physical characteristic makes fish farming safer and more durable.

(2)Good anti-seepage ability. The anti-seepage coefficient of thick rubber pond liner is less than 1×10-13cm/s, which can ensure that the leachate will not leak and contaminate the land due to the liner, rainwater will not pass through the covering layer of the closed site, increase the amount of leachate.The water storage capacity is good, the cost can be reduced in the process of fish farming, and the efficiency of fish farming can be improved.

(3)Good chemical stability. Thick rubber pond liner is the material with the best chemical stability among all HDPE Pond Liner Sheet materials. HDPE Pond Liner Sheet has good corrosion resistance.And it has no irritating smell, will not cause harm to the fish, and ensure the healthy growth of the fish.

(4)A fish tank can isolate pollution, and it can provide fish with a safe and hygienic growth environment. Compared with fish that grow in traditional fish ponds, fish tanks can reduce the damage of soil pollution to fish and reduce the chance of disease.

5. About BPM Geosynthetics

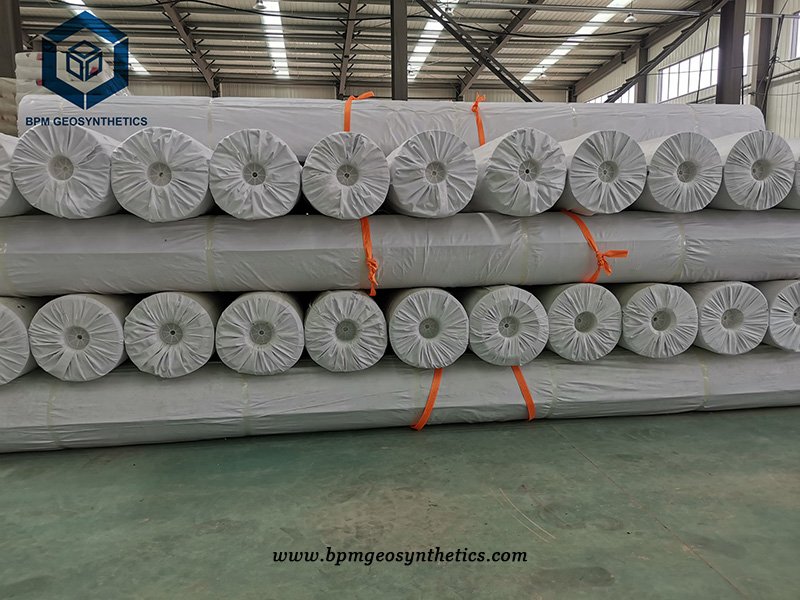

BPM has been specializing in delivering one stop geosynthetics products and solutions to worldwide customers since its foundation in 2007. BPM had provided many types of effective and state of the art geomembranes, geotextiles, geocells, geosynthetic clay liners (GCLs), drainage boards, geogrids to over 81 countries. Our main customers are from Australia, France, Sweden, UK, Hong Kong, Hungary, New Zealand, Poland, Mexico, Ecuador, Brazil, Pakistan, Bangladesh, Thailand, Vietnam, Malaysia, Indonesia, Singapore, Philippines, Sri Lanka, India, UAE, Saudi Arabia, Qatar, Kenya, Ghana, Ethiopia, Somalia, Nigeria, South Africa, Swaziland, Mongolia, etc.

BPM is not only manufacturing best quality geosynthetic products but also providing professional design and installation service. OEM, ODM, custom development and fabrication are also available. If you have any questions or inquiries, please contact us, we will reply as soon as possible.