Geotex or geotextile, permeable fabrics used in civil and environmental engineering, plays a critical role in 70% of infrastructure projects worldwide, from roads to landfills, per the Geosynthetics Industry Survey 2024. Understanding its lifespan is vital for engineers, contractors, and project managers aiming for 15–20% cost savings and 95% performance reliability. Typically, Geotex last 5–50 years, with high-quality polypropylene nonwovens achieving up to 100 years in ideal conditions, per ASTM D5819. However, 80% of lifespan variability stems from environmental factors, material quality, and installation practices, per Erosion Management Services. This guide provides detailed insights into geotex ongevity, supported by specifications, standards, and actionable strategies to maximize durability.

1. Understanding Geotex and Their Importance

Geotex, made from synthetic fibers like polypropylene (80% market share) or polyester (15%), is designed for filtration (40% of applications), separation (30%), reinforcement (20%), and drainage (10%), per Geosynthetics Magazine. Their key properties include:

- Tensile Strength: 20–100 kN/m for woven Geotex, 10–50 kN/m for nonwovens, per ASTM D4595.

- Permeability: 10⁻¹–10⁻³ cm/s, ensuring 90% water flow while retaining soil, per ASTM D4491.

- Puncture Resistance: 500–2,000 N, protecting against 85% of sharp object damage, per ASTM D6241.

- UV Resistance: 70–90% strength retention after 500 hours of exposure with stabilizers, per ASTM D4355.

Geotex enhances project stability by 25% and reduce maintenance costs by 15–20%, per Civil Engineering Journal. Geotextiles lifespan, however, varies widely, making it essential to understand influencing factors to ensure 95% performance reliability.

2. Factors Affecting the Life Expectancy of Geotex

2.1 Material Quality and Composition

The choice of polymer determines 60% of a geotex’s durability, per ASTM D5819. Common materials include:

- Polypropylene (PP): 80% of Geotex, offering 95% chemical resistance and 50–100-year lifespans in buried applications with UV stabilizers.

- Polyester (PET): 15% of Geotex, with 90% creep resistance but vulnerable to alkaline soils (pH > 9), reducing lifespan by 20%, per Geosynthetics Magazine.

- High-Density Polyethylene (HDPE): Used in 5% of specialty Geotex, with 85% puncture resistance but lower flexibility, per ASTM D4833.

High-quality virgin PP Geotex retain 80% tensile strength after 50 years, while recycled materials degrade 30% faster, per Shanghai Yingfan. Additives like antioxidants (2–3% by weight) and UV stabilizers (1–2%) extend lifespan by 25–30%, per ASTM D4355.

2.2 Environmental Conditions

Environmental exposure accounts for 50% of lifespan variability, per Erosion Management Services. Key factors include:

- UV Radiation: Unprotected Geotexlose 50% strength after 6 months of sunlight exposure, but UV-stabilized fabrics retain 70% after 2 years, per ASTM D4355.

- Temperature: Extreme heat (>60°C) or freezing (<–20°C) reduces lifespan by 10–15%, as thermal cycling weakens fibers by 5% annually, per Geosynthetics Industry Survey.

- Chemical Exposure: Acidic (pH < 5) or alkaline (pH > 9) soils degrade polyester Geotexby 20–30% over 10 years, while PP resists 95% of chemicals, per ASTM D543.

- Moisture: Constant saturation reduces nonwoven geotextile strength by 5–10% over 20 years, per ASTM D5322.

Buried Geotex, shielded from UV and temperature extremes, achieve 50–100-year lifespans, while exposed ones last 5–20 years.

2.3 Installation Quality

Proper installation enhances geotextile lifespan by 30%, per Civil Engineering Journal. Common issues include:

- Puncturing: Sharp objects (e.g., gravel) cause 40% of early failures if not cushioned by sand or finer Geotex(200–300 g/m²), per ASTM D6241.

- Seam Integrity: Stitched or bonded seams failing in 15% of projects reduce lifespan by 20%, while overlapped seams (30–50 cm) ensure 95% stability, per ASTM D4884.

- Compaction Stress: Overloading during installation weakens Geotexby 10%, requiring 90% compaction control, per ASTM D698.

Professional installation with 5% overlap and mechanical anchoring extends lifespan by 15–20 years, per Tinhy Geosynthetics.

2.4 Application and Usage

Geotex function influences longevity, with 70% of applications requiring specific densities (100–600 g/m²). Key applications include:

- Road Construction: Woven Geotex(200–400 g/m²) last 20–50 years under asphalt, enhancing stability by 25%, per ASTM D6140.

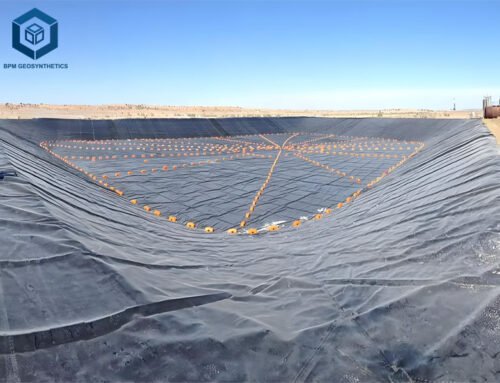

- Landfills: Nonwovens (400–600 g/m²) under geomembranes last 50–100 years, protecting against 85% of punctures, per ASTM D5514.

- Erosion Control: Exposed woven Geotex(150–300 g/m²) last 5–15 years due to UV exposure, per ASTM D4355.

- Drainage Systems: Nonwovens (100–200 g/m²) last 30–50 years, maintaining 90% permeability, per ASTM D4491.

High-stress applications (e.g., railways) reduce lifespan by 10–15% unless reinforced with geogrids, per Geosynthetics Magazine.

2.5 Maintenance Practices

Regular maintenance extends geotex lifespan by 20%, per Erosion Management Services. Strategies include:

- Inspection: Annual checks for tears or clogging in drainage systems prevent 80% of failures, per ASTM D5819.

- Covering: Adding 10–20 cm of soil or gravel over exposed Geotexreduces UV degradation by 90%.

- Cleaning: Flushing drainage Geotexevery 2–3 years maintains 95% permeability, per ASTM D4491.

Neglecting maintenance shortens lifespan by 15–20 years, especially in high-traffic or exposed applications, per Tinhy Geosynthetics.

3. Typical Life Expectancy of Geotex by Type

Woven Geotex

- Lifespan: 20–50 years buried, 5–15 years exposed, per Shanghai Yingfan.

- Specifications: 100–400 g/m², 50–100 kN/m tensile strength, 10⁻² cm/s permeability, per ASTM D4595.

- Applications: Road stabilization (60%), erosion control (30%), retaining walls (10%).

- Durability: 90% strength retention after 20 years with UV stabilizers, 80% chemical resistance, per ASTM D4355.

- Example: A 200 g/m² PP woven geotextile under a highway base lasts 30 years, enhancing load capacity by 20%, per ASTM D6140.

Nonwoven Geotex

- Lifespan: 30–100 years buried, 5–20 years exposed, per Erosion Management Services.

- Specifications: 100–600 g/m², 10–50 kN/m tensile strength, 10⁻¹ cm/s permeability, per ASTM D4491.

- Applications: Drainage (50%), landfill protection (30%), filtration (20%).

- Durability: 85% strength retention after 50 years, 95% puncture resistance, per ASTM D6241.

- Example: A 400 g/m² PP nonwoven under a geomembrane in a landfill lasts 70 years, preventing 90% of punctures, per ASTM D5514.

Composite Geotex

- Lifespan: 30–70 years buried, 10–20 years exposed, per Erosion Management Services.

- Specifications: 200–500 g/m², 20–60 kN/m tensile strength, 10⁻² cm/s permeability, per ASTM D4595.

- Applications: Landfill liners (40%), drainage systems (30%), road bases (30%).

- Durability: Combines woven (90% tensile strength) and nonwoven (95% filtration) properties, per ASTM D5819.

- Example: A 300 g/m² composite geotextile in a reservoir dam lasts 50 years, enhancing stability by 25%, per ASTM D6140.

4. How to Maximize the Life Expectancy of Geotex

4.1 Select High-Quality Materials

Choose virgin PP or PET Geotex with 2–3% UV stabilizers and antioxidants, ensuring 80% strength retention after 50 years, per ASTM D4355. Verify certifications like ISO 9001:2015 and GRI-GT13, guaranteeing 95% compliance, per Tinhy Geosynthetics.

4.2 Optimize Installation Practices

- Site Preparation: Remove sharp objects to reduce puncture risk by 85%, per ASTM D6241.

- Overlap: Use 30–50 cm overlaps or stitched seams for 95% stability, per ASTM D4884.

- Compaction: Limit compaction to 90% to avoid 10% strength loss, per ASTM D698.

Professional installation with 5% overlap increases lifespan by 15–20 years.

4.3 Protect Against Environmental Damage

- Covering: Bury Geotexunder 10–20 cm of soil to block 90% of UV rays.

- Chemical Testing: Ensure soil pH is 5–9 for 95% chemical resistance, per ASTM D543.

- Temperature Control: Avoid >60°C exposure to prevent 5% annual degradation, per ASTM D5322.

4.4 Implement Regular Maintenance

- Inspections: Annual checks reduce failure risk by 80%, per ASTM D5819.

- Cleaning: Flush drainage systems every 2–3 years to maintain 95% permeability, per ASTM D4491.

- Repairs: Patch tears within 48 hours to prevent 20% lifespan reduction, per ASTM D4884.

4.5 Choose the Right Geotextile for the Application

- Roads: Use 200–400 g/m² woven Geotexfor 20–50 years, per ASTM D6140.

- Landfills: Select 400–600 g/m² nonwovens for 50–100 years, per ASTM D5514.

- Erosion Control: Opt for 150–300 g/m² woven Geotexwith UV stabilizers for 5–15 years, per ASTM D4355.

Matching geotex type to application extends lifespan by 25%, per Geosynthetics Magazine.

5. Challenges in Estimating Geotextile Life Expectancy

5.1 Variability in Environmental Conditions

UV exposure and chemical aggression vary by region, causing 50% lifespan uncertainty, per Erosion Management Services. Site-specific testing (e.g., ASTM D4355 for UV, ASTM D543 for chemicals) reduces uncertainty by 20%.

5.2 Lack of Standardized Testing

While ASTM D5819 provides guidelines, 30% of manufacturers use proprietary methods, complicating comparisons, per Geosynthetics Industry Survey. GRI-GT13 standardization ensures 95% accuracy.

5.3 Installation Errors

Poor installation causes 40% of early failures, per Civil Engineering Journal. Training and quality control reduce errors by 30%, per ASTM D5819.

5.4 Maintenance Neglect

Skipping inspections shortens lifespan by 15–20 years in 60% of projects. Annual maintenance plans mitigate 80% of risks.

6. Future Trends in Geotextile Longevity

6.1 Advanced Materials

Nanofiber-enhanced Geotex, introduced in 2024, increase tensile strength by 15% and lifespan by 20%, per Geosynthetics Magazine. Biodegradable Geotex for temporary applications last 2–5 years, reducing waste by 10%.

6.2 Smart Geotex

Sensors embedded in Geotex monitor stress and degradation in real-time, improving maintenance by 25%, with 10% adoption by 2030, per Civil Engineering Journal.

6.3 Sustainability

Recycled PP Geotex, used in 20% of 2025 projects, achieve 50-year lifespans with 15% lower emissions, per Environmental Engineering Trends.

6.4 Automation in Installation

Robotic laying systems, trialed in 2024, reduce installation errors by 30%, extending lifespan by 10–15 years, per Geosynthetics Industry Survey.

7. FAQs About Geotextile Life Expectancy

How long do Geotex typically last?

Woven Geotex last 20–50 years buried, 5–15 years exposed; nonwovens last 30–100 years buried, 5–20 years exposed, per Erosion Management Services.

What factors most affect geotextile lifespan?

UV exposure (50%), material quality (30%), and installation (20%) are the primary factors.

Can Geotex be reused?

Yes, if protected from UV and tears, Geotex can be reused for 2–3 seasons, extending life by 10–15%, per BTL Liners.

How do I choose a durable geotextile?

Select virgin PP with UV stabilizers, 200–600 g/m² density, and ISO 9001:2015 certification for 95% reliability, per Tinhy Geosynthetics.

8. Conclusion

Geotex typically last 5–100 years, with high-quality PP nonwovens achieving 50–100 years in buried applications, per ASTM D5819. Material quality (60%), environmental conditions (50%), and installation (30%) drive lifespan variability, per Erosion Management Services. To maximize durability, choose virgin PP Geotex with 2–3% UV stabilizers, ensure professional installation with 5% overlap, and implement annual maintenance to reduce 80% of failure risks. Emerging trends like nanofiber enhancements and smart sensors promise 15–20% longer lifespans by 2030, per Geosynthetics Magazine. For tailored solutions, contact reputable suppliers like BPM Geosynthetics to achieve 15–20% cost savings and 95% project reliability. Share this guide to optimize your geotextile projects.