Geotextiles, permeable synthetic fabrics made from polymers like polypropylene or polyester, are critical geosynthetic materials used in civil engineering, environmental, and construction projects. These versatile geotextile fabrics enhance soil stability, provide filtration, drainage, separation, and reinforcement, making them indispensable in applications such as road construction, erosion control, landfills, and water management. According to a 2023 market report, the global geosynthetics market, including geotextiles, is projected to reach $13.2 billion by 2027, driven by infrastructure development and environmental regulations. A key question for engineers and project managers is: What is the life expectancy of a geotextile? Generally, geotextiles can last 20–200 years in buried applications, depending on material quality, environmental conditions, and installation practices. However, this is an estimate, and actual lifespan varies based on several factors. This article explores these factors in detail, providing specifications, parameters, and actionable insights to help you maximize geotextile durability in your projects.

1. Understanding Geotextiles

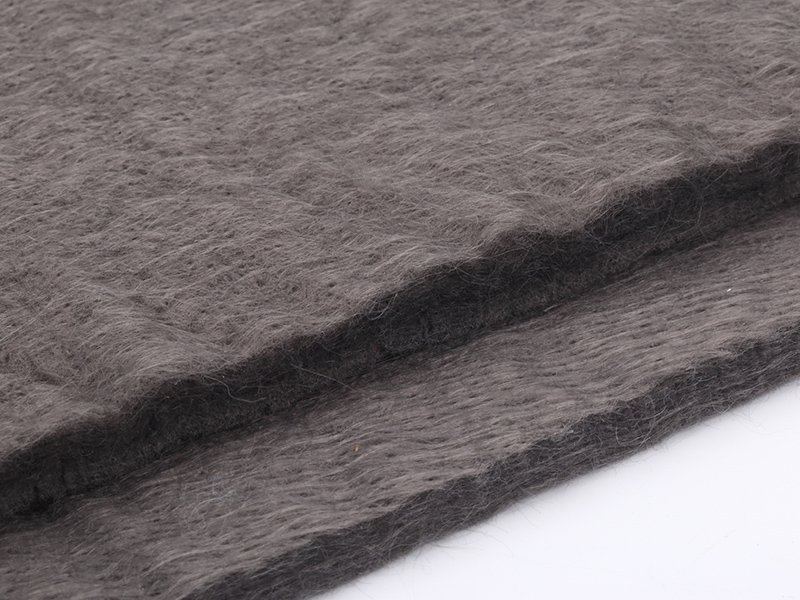

Geotextiles are synthetic materials, typically made from polypropylene (PP), polyester (PET), or polyethylene, designed to improve soil performance in geotechnical applications. They are classified into two main types based on manufacturing methods:

- Woven Geotextiles: Produced by interlacing PP or PET yarns, offering high tensile strength (20–100 kN/m) for reinforcement and stabilization in roads and embankments.

- Non-Woven Geotextiles: Made through needle-punching or thermal bonding of PP or PET fibers, with weights of 100–800 g/m², ideal for filtration and drainage in landfills and drainage systems.

Geotextiles are used in diverse applications, including soil separation, erosion control, drainage, and protection of geomembranes. Their permeability (0.1–0.6 cm/s) and puncture resistance (CBR: 1.5–8 kN) make them suitable for harsh environments. However, their lifespan depends on multiple variables, which we’ll explore below.

2. Factors Influencing the Life Expectancy of Geotextiles

The durability of geotextiles is influenced by material properties, environmental conditions, and project-specific factors. Below are the key factors affecting their lifespan, supported by data and industry insights.

2.1 Material Composition

The type of polymer used significantly impacts geotextile longevity. The two primary materials are:

- Polypropylene (PP): Lightweight, with excellent chemical resistance and UV stability, PP geotextiles are ideal for drainage and filtration. They have a tensile strength of 8–120 kN/m and a lifespan of 20–100 years in buried applications when stabilized with UV inhibitors and antioxidants. PP geotextiles are less durable in high-temperature environments (>70°C) but resist acidic and alkaline soils effectively.

- Polyester (PET): Known for higher strength (10–90 kN/m) and durability, PET geotextiles are suited for load-bearing applications like dams and tunnels. They offer a lifespan of 50–200 years in buried conditions due to their resistance to high temperatures and abrasion. However, PET is more susceptible to hydrolysis in alkaline environments (pH > 10), which can reduce lifespan if not addressed.

High-quality geotextiles use 100% virgin polymers with additives like antioxidants, thermal stabilizers, and UV inhibitors to enhance durability. For example, EarthShield’s PP geotextiles, with a density of 940 g/m³, achieve a lifespan of up to 200 years in buried applications due to advanced stabilization.

2.2 Environmental Conditions

Geotextiles are exposed to various environmental stressors that affect their longevity:

- UV Exposure: Prolonged sunlight exposure degrades geotextiles, particularly PP, due to UV radiation breaking down polymer chains. Unstabilized PP geotextiles may lose 50% of their strength within 1–2 years if exposed. Buried geotextiles, protected from UV rays, can last decades longer. Stabilized PP geotextiles with UV inhibitors can withstand limited exposure for 3–5 years.

- Temperature: Extreme temperatures impact geotextile performance. PP geotextiles function well in temperatures from -40°C to 70°C, while PET geotextiles handle up to 100°C. High temperatures can accelerate polymer degradation, reducing lifespan by 20–30% in exposed conditions.

- Chemical Exposure: Geotextiles in landfills or mining projects face acidic or alkaline soils, which can degrade PET geotextiles in high-pH environments (e.g., near concrete). PP geotextiles resist chemical corrosion better, maintaining performance in pH ranges of 2–12.

- Biological Degradation: While geotextiles are generally resistant to microbial attack, biological clogging (e.g., iron ochre in drainage systems) can reduce permeability without degrading the polymer. Regular maintenance can mitigate this issue.

2.3 Installation Quality

Proper installation is critical for maximizing geotextile lifespan. Key considerations include:

- Subgrade Preparation: Sharp objects like stones or roots can puncture geotextiles, reducing their effectiveness. A smooth, compacted subgrade with a sand or clay layer minimizes damage. For example, in a 2021 Cambodian landfill project, 400 g/m² non-woven geotextiles were laid beneath a 1.5 mm HDPE geomembrane to prevent punctures, extending the system’s lifespan to over 50 years.

- Seam and Connection Quality: Geotextiles are joined by stitching, welding, or bonding. Poor seams can lead to tearing or separation, reducing lifespan by 10–20%. High-quality needle-punched non-woven geotextiles, like those from BPM Geosynthetics, use advanced stitching to ensure integrity.

- Handling and Transportation: Improper handling, such as dragging geotextiles during transport, can cause tears or abrasions. EarthShield recommends cleaning transport equipment and minimizing drag to maintain geotextile integrity.

2.4 Thickness and Density

Geotextile thickness and density directly affect durability. Common specifications include:

- Woven Geotextiles: 120–500 g/m², with thicker fabrics (e.g., 400 g/m²) offering higher tensile strength (20–100 kN/m) and puncture resistance for heavy-duty applications like road stabilization.

- Non-Woven Geotextiles: 100–800 g/m², with denser fabrics (e.g., 600 g/m²) used in landfills for protection and filtration, achieving lifespans of 50–100 years when buried.

Thicker geotextiles (e.g., 600 g/m²) provide better protection against mechanical stress, extending lifespan by 15–25% compared to thinner options (e.g., 200 g/m²).

2.5 Application and Maintenance

The project type and maintenance practices influence geotextile longevity:

- Buried vs. Exposed Applications: Buried geotextiles, such as those in roadbeds or landfills, are shielded from UV and weathering, achieving lifespans of 20–200 years. Exposed geotextiles, like those in erosion control, may last 3–20 years with proper stabilization.

- Maintenance: Regular inspections and cleaning of drainage systems prevent clogging, preserving geotextile permeability. For example, in a Jaipur slope erosion control project, Ocean Global’s 400 g/m² non-woven geotextiles maintained performance for 15 years with minimal maintenance.

3. Geotextile Applications and Their Impact on Lifespan

Geotextiles are used in various applications, each affecting their lifespan differently:

- Road and Railway Construction: Woven PP geotextiles (200–400 g/m²) provide soil stabilization, with a lifespan of 50–100 years when buried. Their high tensile strength (20–80 kN/m) resists mechanical stress from traffic loads.

- Landfill Liners: Non-woven PET geotextiles (400–600 g/m²) protect geomembranes, achieving 50–100 years in buried conditions due to chemical resistance.

- Erosion Control: Exposed PP geotextiles (150–300 g/m²) in coastal or riverbank projects last 3–20 years, depending on UV stabilization.

- Drainage Systems: Non-woven geotextiles (100–400 g/m²) ensure filtration, with lifespans of 20–50 years in well-maintained systems.

A 2023 study by the International Geosynthetics Society noted that PP geotextiles in buried drainage applications maintained 90% of their tensile strength after 20 years, highlighting their durability when protected.

4. Standards and Testing for Geotextile Longevity

Geotextile lifespan is validated through rigorous testing and standards:

- ASTM D4595: Measures tensile strength (8–120 kN/m), ensuring geotextiles withstand mechanical loads.

- ASTM D4491: Assesses permeability (0.1–0.6 cm/s), critical for drainage applications.

- ISO 9001 and ISO 14001: Certifications held by manufacturers like BPM Geosynthetics ensure quality and environmental compliance.

- GRI-GT Standards: Specify durability requirements, with tests indicating PP geotextiles can last up to 200 years in optimal conditions.

EarthShield’s geotextiles, for instance, meet ASTM and GRI standards, with a documented lifespan of 50–100 years in landfill applications when paired with HDPE geomembranes.

5. How to Maximize Geotextile Life Expectancy

To ensure geotextiles achieve their maximum lifespan, consider the following:

- Choose the Right Material: Select PP for chemical resistance in acidic soils or PET for high-strength applications like dams. Consult engineers to match specifications to project needs.

- Ensure Proper Installation: Prepare a smooth subgrade, use professional welding or stitching, and avoid stretching geotextiles during installation.

- Protect from UV Exposure: Use buried installations or UV-stabilized geotextiles for exposed applications.

- Regular Maintenance: Inspect drainage systems for clogging and monitor exposed geotextiles for wear.

- Select Appropriate Thickness: Use denser geotextiles (e.g., 600 g/m²) for high-stress applications like landfills.

6. Related Products and Considerations

Geotextiles are often used with other geosynthetics to enhance performance:

- Geomembranes: Impermeable liners paired with geotextiles for protection. A 1.5 mm HDPE geomembrane with a 400 g/m² geotextile can last 50–100 years in landfills.

- Geotubes: High-strength woven geotextiles filled with sand for coastal protection, with lifespans of 20–50 years in harsh environments.

- Geogrids: Used with geotextiles for reinforcement, enhancing stability in roadbeds.

Combining geotextiles with geomembranes, as in composite geomembranes (200–1500 g/m²), increases anti-seepage performance and durability.

7. Conclusion

The life expectancy of geotextiles ranges from 20–200 years in buried applications, with exposed geotextiles lasting 3–20 years, depending on material quality, environmental conditions, installation, and maintenance. Polypropylene geotextiles offer excellent chemical resistance, while polyester geotextiles provide superior strength for load-bearing projects. By selecting high-quality materials, ensuring proper installation, and protecting against UV and chemical exposure, engineers can maximize geotextile durability. For tailored solutions, contact with BPM Geosynthetics who offer ASTM-compliant products and installation support. Understanding these factors ensures geotextiles deliver long-term performance in your projects.