Pond liners are essential for creating durable, leak-proof water features, from small garden ponds to large-scale aquaculture and industrial reservoirs. With global water management investments projected to reach USD 1 trillion by 2030, driven by urbanization and environmental regulations, pond liners are critical for preventing seepage and ensuring sustainability. A key question for homeowners, farmers, and engineers is: What Is Pond Liner Price ? This comprehensive guide explores the cost structure of pond liners, providing detailed specifications, parameters, and actionable insights to optimize budgets while ensuring durability and performance.

1. What Is a Pond Liner?

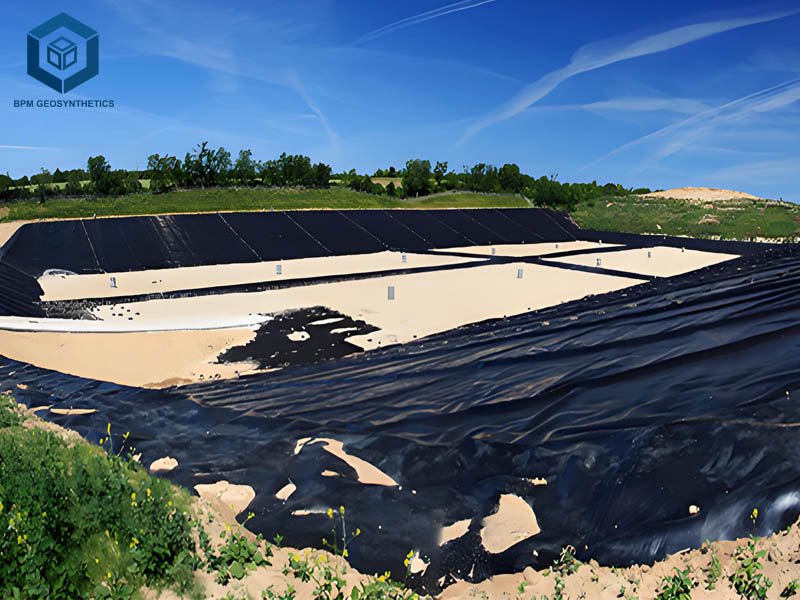

A pond liner is a waterproof membrane used to prevent water seepage in artificial ponds, reservoirs, and containment systems. Made from materials like high-density polyethylene (HDPE), linear low-density polyethylene (LLDPE), ethylene propylene diene monomer (EPDM), polyvinyl chloride (PVC), or reinforced polyethylene (RPE), pond liners offer hydraulic conductivities of ≤10⁻¹¹ cm/s (ASTM D5887), reducing seepage by 95% compared to traditional clay or concrete. They are critical for applications such as garden ponds, fish farms, stormwater retention, and industrial wastewater systems, ensuring environmental safety and structural integrity.

Types of Pond Liners

Pond liners come in various types, each tailored to specific applications with distinct cost implications:

- HDPE Liners: High tensile strength (27 kN/m, ASTM D6693) and chemical resistance, ideal for large ponds and industrial applications. Price range: $0.35–$2.50/m².

- LLDPE Liners: Flexible, with 10% better elongation (ASTM D6693), suitable for irregular surfaces. Price range: $0.50–$2.00/m².

- EPDM Liners: UV-resistant and fish-safe, perfect for garden ponds and water features. Price range: $1.00–$6.00/m².

- PVC Liners: Cost-effective but less durable, used for small ponds. Price range: $0.50–$2.00/m².

- RPE Liners: Lightweight and puncture-resistant (154–680 lbs, ASTM D5034), ideal for large ponds. Price range: $0.40–$1.50/m².

- Geosynthetic Clay Liners (GCLs): Combine bentonite clay with geotextiles for industrial applications. Price range: $1.50–$5.00/m².

In 2024, HDPE liners held a 40% market share due to their affordability and durability.

Key Specifications and Parameters

Pond liner performance depends on technical parameters that influence pricing:

- Thickness: Ranges from 0.3–3.0 mm (12–60 mil). Thicker liners (40–45 mil) cost more but offer better puncture resistance (640 N, ASTM D4833).

- Tensile Strength: 27–345 kN/m (ASTM D6693/D7004), ensuring stability in high-stress environments.

- Puncture Resistance: 154–680 lbs (ASTM D4833/D5884), critical for rocky terrains.

- UV Resistance: 90% strength retention after 500 hours (ASTM D4355), essential for exposed liners.

- Roll Size: Standard rolls are 5–10 m wide and 50–200 m long, impacting bulk pricing.

- Density: 0.941–0.965 g/cm³ for HDPE, ensuring durability.

2. Factors Influencing Pond Liner Price

Pond liner prices in 2025 range from $0.35 to $6.00 per square meter, influenced by material, thickness, manufacturing, and project requirements. Below, we explore these factors in detail.

2.1 Pond Liner Price – Material Type

The choice of material significantly impacts pricing:

- HDPE: $0.35–$2.50/m², offering durability and chemical resistance for large ponds and landfills.

- LLDPE: $0.50–$2.00/m², flexible for irregular surfaces like aquaculture ponds.

- EPDM: $1.00–$6.00/m², fish-safe and UV-resistant for garden ponds.

- PVC: $0.50–$2.00/m², affordable but less durable and not always fish-safe.

- RPE: $0.40–$1.50/m², lightweight with high puncture resistance (154 lbs, ASTM D5884).

- GCLs: $1.50–$5.00/m², used in industrial applications for enhanced sealing.

Petroleum-based materials like HDPE and LLDPE saw a 7–15% price increase in Q1 2025 due to crude oil price volatility.

2.2 Pond Liner Price – Thickness

Thicker liners cost more due to increased material usage and enhanced performance:

- 3–0.5 mm (12–20 mil): $0.35–$1.00/m², suitable for small garden ponds.

- 75–1.0 mm (30–40 mil): $0.80–$2.50/m², ideal for medium ponds and fish farms.

- 5–3.0 mm (45–60 mil): $1.50–$6.00/m², used for large industrial reservoirs.

For example, a 0.75 mm HDPE liner for a 1-acre pond costs $0.62–$1.20/m², while a 0.3 mm PVC liner for a 12×12 ft pond costs $0.50–$1.00/m².

2.3 Pond Liner Price – Manufacturing Process

Production methods affect costs:

- Extrusion: Common for HDPE and LLDPE, cost-effective at $0.35–$2.00/m².

- Calendering: Used for PVC, increasing costs to $0.50–$2.00/m² due to complex processing.

- Weaving: RPE liners with woven reinforcement cost $0.40–$1.50/m².

- Lamination: EPDM liners with UV-resistant coatings cost $1.00–$6.00/m².

2.4 Pond Liner Price – Project Scale and Order Volume

Larger projects benefit from economies of scale. Orders exceeding 10,000 m² from suppliers like BPM Geosynthetics reduce costs by 20–30%. For example, a 1-acre HDPE liner at $0.62/m² drops to $0.43/m² for orders over 10,000 m².

2.5 Pond Liner Price – Installation and Logistics

Installation costs, including labor, welding, and site preparation, add 20–30% to total expenses. For instance, hot wedge welding for HDPE liners increases costs by 10–15% but ensures 95% seam reliability. Remote locations or rocky terrains can raise logistics costs by 2–3 times. Underlayment, costing $0.25–$0.40/m², protects liners from punctures, adding 5–10% to costs.

2.6 Pond Liner Price – Regional and Supplier Variations

Prices vary by region due to labor, transportation, and market dynamics:

- North America/Europe: $0.80–$6.00/m², driven by strict regulations and high labor costs ($15–$25/hour).

- Asia-Pacific: $0.35–$2.50/m², benefiting from low-cost production in China ($2–$5/hour).

- Africa: $0.50–$2.00/m², often using thinner liners (0.5–0.75 mm) for cost savings.

Suppliers like BPM Geosynthetics and Haoyang Environmental offer competitive pricing, while premium brands like Firestone charge higher for certified products.

2.7 Pond Liner Price – Certifications and Quality Standards

Liners meeting ASTM D6365 or ISO 9001 standards cost 10–15% more but ensure 95% reliability, reducing risks of failure costing $50,000–$200,000 in repairs. Non-certified liners may be cheaper but risk defects, especially in harsh environments.

3. Pond Liner Price Range in 2025

Based on 2025 market data, pond liner prices range from $0.35 to $6.00 per square meter:

- HDPE Liners: $0.35–$2.50/m², with 0.5 mm liners at $0.35–$1.00/m² and 1.5 mm at $1.50–$2.50/m².

- LLDPE Liners: $0.50–$2.00/m², ideal for flexible applications.

- EPDM Liners: $1.00–$6.00/m², used for fish-safe garden ponds.

- PVC Liners: $0.50–$2.00/m², budget-friendly for small ponds.

- RPE Liners: $0.40–$1.50/m², lightweight for large ponds.

- GCLs: $1.50–$5.00/m², for industrial applications.

For example, a 12×12 ft (144 m²) EPDM liner at $1.50/m² costs $216, while a 1-acre (4,047 m²) HDPE liner at $0.62/m² costs $2,509.

Price Comparison by Supplier

- BPM Geosynthetics: $0.35–$2.50/m² for HDPE liners, with 20-day shipping to 86+ countries.

- Agtec: $0.40–$1.50/m² for RPE liners, custom-fabricated for large ponds.

- Firestone: $1.00–$6.00/m² for premium EPDM liners with 20-year warranties.

Bulk orders and local sourcing can reduce costs by 10–20%.

4. Market Trends Impacting Pond Liner Prices

The pond liner market is evolving, influenced by several trends:

Sustainability and Eco-Friendly Materials

Eco-friendly liners using recycled HDPE or biodegradable additives are emerging, increasing costs by 5–10% due to R&D. These align with EU sustainability standards, reducing emissions by 10%.

Infrastructure Growth

Asia-Pacific, with a 40% market share, drives demand due to aquaculture and irrigation projects in China and India, stabilizing prices at $0.35–$2.50/m².

Technological Advancements

Reinforced liners like RPE (30 mil, 154 lbs puncture resistance) reduce thickness requirements by 50% compared to HDPE (60 mil), saving 10–15% on costs. Sensor-embedded liners for leak detection add 20% to costs but reduce maintenance by 10%.

Supply Chain Dynamics

Petroleum price volatility raised HDPE costs by 7–15% in Q1 2025. Geopolitical tensions and shipping delays may increase prices by 5% in 2025.

5. Applications and Cost Benefits

Pond liners offer significant cost savings compared to traditional materials like concrete ($50–$130/m²), reducing material costs by 15–25%. Key applications include:

Garden Ponds

EPDM liners (0.75–1.0 mm, $1.00–$6.00/m²) ensure fish safety and UV resistance, saving $500–$2,000 in maintenance over 20 years.

Aquaculture

HDPE liners (0.5–1.0 mm, $0.35–$1.20/m²) provide 90% chemical resistance, extending system lifespans by 10–20 years.

Stormwater Retention

RPE liners (0.75 mm, $0.40–$1.50/m²) reduce installation costs by 10% due to lightweight panels.

Industrial Reservoirs

GCLs ($1.50–$5.00/m²) ensure 95% seepage control, saving $100,000–$500,000 in environmental cleanup.

6. How to Optimize Pond Liner Costs

To maximize value and minimize expenses, consider these strategies:

Bulk Ordering

Orders over 10,000 m² from suppliers like BPM Geosynthetics secure 20–30% discounts. For example, a 1-acre HDPE liner at $0.62/m² drops to $0.43/m².

Local Sourcing

Sourcing from regional suppliers like Haoyang Environmental in Asia-Pacific reduces shipping costs by 15%.

Choosing Certified Suppliers

Suppliers meeting ASTM D6365 or ISO 9001 standards, like Firestone, ensure 95% reliability, avoiding costly repairs.

Lifecycle Cost Analysis

RPE liners (30 mil, $0.40–$1.50/m²) last 20–40 years, saving 20% on lifetime costs compared to PVC (10 years).

Using Design Software

Tools like pond liner calculators optimize sizing, reducing material waste by 10%. Contact suppliers for free consultations.

Proper Installation Techniques

Using hot wedge welding and skilled technicians ensures 95% seam reliability, reducing repair costs by 15%. Underlayment ($0.25–$0.40/m²) prevents punctures.

7. Case Studies: Real-World Cost Examples

US Garden Pond (2024)

Webb’s Water Gardens supplied 144 m² of 45 mil EPDM liner at $1.50/m² for a 12×12 ft pond, costing $216 and saving $500 in maintenance over 20 years.

Philippine Aquaculture Project (2024)

BPM Geosynthetics provided 30,000 m² of 1.0 mm HDPE liner at $0.80/m², costing $24,000 and ensuring 20-year durability.

Australian Reservoir (2024)

Agtec supplied 65,000 m² of 30 mil RPE liner at $1.00/m², saving $50,000 in installation costs due to lightweight panels.

8. Choosing the Right Pond Liner for Your Project

Selecting the appropriate pond liner involves balancing cost and performance:

- Garden Ponds: EPDM liners (0.75–1.0 mm, $1.00–$6.00/m²) for fish safety and flexibility.

- Aquaculture: HDPE or LLDPE liners (0.5–1.0 mm, $0.35–$2.00/m²) for durability.

- Large Reservoirs: RPE liners (0.75 mm, $0.40–$1.50/m²) for lightweight installation.

- Industrial Applications: GCLs ($1.50–$5.00/m²) for enhanced sealing.

Consult suppliers like BPM Geosynthetics, Haoyang Environmental, or Agtec for tailored quotes and project-specific recommendations.

9. Conclusion

Pond liner prices in 2025 range from $0.35 to $6.00 per square meter, influenced by material, thickness, manufacturing, installation, and regional factors. By leveraging bulk ordering, local sourcing, certified suppliers, lifecycle cost analysis, and proper installation, you can save 10–30% while ensuring durable, leak-proof solutions.

For tailored quotes and expert guidance, contact reputable suppliers like BPM Geosynthetics, who meet ASTM and ISO standards. With the pond liner market growing steadily, strategic choices today will optimize budgets and enhance project outcomes for decades.