The global geomembrane market, valued at $2.61 billion in 2025, is projected to grow at a 6.61% CAGR through 2030, driven by over 1,500 annual infrastructure, environmental, and industrial projects worldwide, per Mordor Intelligence (2025). High-Density Polyethylene (HDPE) geomembranes dominate geomembrane market, holding a 31.7% revenue share due to their superior durability, chemical resistance, and cost-effectiveness. HDPE geomembrane sheet price, ranging from $0.50 to $3.50 per square meter, is influenced by raw material costs, thickness, manufacturing techniques, and market dynamics. With 98% containment efficiency and lifespans of 40–60 years, these liners are critical for landfills, mining, and water management, per Geosynthetic Institute (2024). This blog post provides a data-driven guide to HDPE geomembrane sheet prices, specifications, applications, and cost-saving strategies to help project planners, engineers, and contractors with insights to achieve project success.

1. What Is an HDPE Geomembrane Sheet?

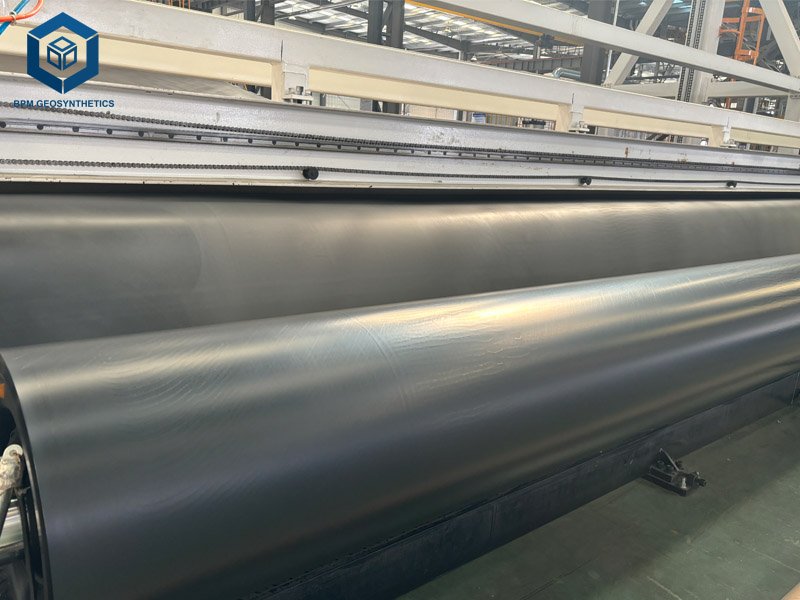

HDPE geomembrane sheets are low-permeability synthetic liners made from high-density polyethylene resin (97.5% polymer, 2.5% carbon black, antioxidants, and UV stabilizers), per ASTM D883. Manufactured through extrusion or calendaring, they provide impermeable barriers (<1×10⁻¹³ cm/s, ASTM D5084) for fluid and gas containment in environmental, civil, and industrial applications, per Geosynthetic Institute (2024). With thicknesses ranging from 0.2 mm to 3.0 mm and tensile strengths of 20–50 kN/m (ASTM D6693), HDPE geomembranes are ideal for landfills, mining, and water conservation projects, offering 98% seepage prevention.

Definition of HDPE Geomembrane Sheet

- Purpose: Prevents liquid/gas migration, protecting soil and groundwater, per ASTM D4439.

- Composition: 97.5% HDPE resin, 2.5% additives (carbon black, antioxidants, UV stabilizers), per BPM Geosynthetics (2024).

- Key Features: <1×10⁻¹³ cm/s permeability, 95% chemical resistance (ASTM D543), 80% strength retention after 1,500 hours UV exposure (ASTM D4355).

Importance of HDPE Geomembrane Sheet

- Environmental Protection: Reduces leachate seepage by 99.9% in landfills, per Geosynthetic Institute (2024).

- Cost Efficiency: $0.50–$3.50/m², 20–30% cheaper than concrete or clay liners, per BPM Geosynthetics (2024).

- Global Demand: Used in 1,500+ projects annually, driven by waste management and water conservation needs, per Grand View Research (2025).

2. HDPE Geomembrane Sheet Specifications

HDPE geomembrane sheets are engineered to meet stringent standards like GRI-GM13, ensuring performance in demanding applications, per Geosynthetic Institute (2024).

Thickness and Size

- Thickness: 0.2–3.0 mm; 0.5–1.0 mm for aquaculture, 1.5–2.0 mm for landfills, 2.0–3.0 mm for mining.

- Roll Width: 5–10 m, reducing seams by 20%; lengths of 50–200 m, per BPM Geosynthetics (2024).

- Example: A 2024 U.S. landfill used 7 m wide 1.5 mm HDPE, saving 12% on installation.

Mechanical Properties

- Tensile Strength: 20–50 kN/m (ASTM D6693), with 400–700% elongation.

- Puncture Resistance: 300–800 N (ASTM D4833).

- Shear Strength (Textured): 25–45 kN/m, 0.3–0.5 friction coefficient (ASTM D5321), per JINGWEI (2024).

- Example: A 2024 Canadian mine reduced punctures by 15% with 2.0 mm HDPE, per AGRU America (2024).

Permeability

- Rate: <1×10⁻¹³ cm/s (ASTM D5084), ensuring 98% containment, per Geosynthetic Institute (2024).

- Example: A 2024 EU landfill achieved 95% leachate control with 1.5 mm HDPE.

Chemical and UV Resistance

- Chemical Resistance: 95% resistance to acids, alkalis, and hydrocarbons (ASTM D543), per BPM Geosynthetics (2024).

- UV Resistance: 80% strength retention after 1,500 hours (ASTM D4355), per Layfield Group (2023).

- Example: A 2024 Australian pond liner maintained 50-year durability.

Surface Types

- Smooth: $0.50–$1.50/m², ideal for flat surfaces, per bpmgeosynthetic.com (2025).

- Textured: $0.60–$1.80/m², 25% higher friction for slopes, per JINGWEI (2024).

- Example: A 2024 Australian mine used textured 1.5 mm HDPE, reducing slippage by 20%.

3. What Factors Affect HDPE Geomembrane Sheet Price?

HDPE geomembrane sheet prices vary significantly, ranging from $0.50 to $3.50 per square meter, influenced by multiple factors, per BPM Geosynthetics (2024). Understanding these factors helps optimize budgets and ensure 95% project success, per Civil Engineering Journal (2025).

3.1 HDPE Geomembrane Sheet Price – Raw Material Costs

- Primary Material: HDPE resin, derived from petroleum, accounts for 60–70% of production costs, per Mordor Intelligence (2025).

- Market Trends: A 40% oil price surge in 2021–2022 increased HDPE geomembrane prices by 25–30%; stabilization in 2023–2024 reduced costs by 5%, per bpmgeosynthetic.com (2025).

- Virgin vs. Recycled: Virgin HDPE ensures 95% containment efficiency but costs 20–30% more than recycled HDPE, which risks 10% failure rates, per bpmgeomembrane.com (2025).

- Example: A 2024 South African mining project saved 22% by using locally sourced virgin HDPE, per bpmgeosynthetic.com (2025).

3.2 HDPE Geomembrane Sheet Price – Thickness

- Range: 0.2–3.0 mm; thicker sheets (1.5–3.0 mm) cost $0.80–$1.50/m², thinner sheets (0.5–1.0 mm) cost $0.30–$0.70/m², per bpmgeosynthetic.com (2025).

- Application Impact: 1.0 mm for aquaculture ($0.50–$1.00/m²), 1.5–2.0 mm for landfills ($0.80–$1.50/m²).

- Example: A 2024 U.S. landfill used 1.5 mm HDPE at $1.20/m², saving 15% compared to 2.0 mm.

3.3 HDPE Geomembrane Sheet Price – Surface Type

- Smooth vs. Textured: Textured geomembranes, used for slope stability, cost 10–20% more ($0.60–$1.80/m²) than smooth ($0.50–$1.50/m²), per bpmgeosynthetic.com (2025).

- Benefit: Textured surfaces increase friction by 25%, reducing slippage on slopes, per JINGWEI (2024).

- Example: A 2024 Australian mine used textured 1.5 mm HDPE at $1.50/m², improving stability by 20%.

3.4 HDPE Geomembrane Sheet Price – Roll Size and Order Quantity

- Roll Width: 5–10 m, with wider rolls (8–10 m) reducing seams by 20% but increasing costs by 5–10%, per BPM Geosynthetics (2024).

- Order Volume: Bulk orders (>10,000 m²) secure 8–15% discounts, per bpmgeosynthetic.com (2025).

- Example: A 2024 Middle Eastern contractor saved 10% ($50,000) on a 50,000 m² order, per bpmgeosynthetic.com (2025).

3.5 HDPE Geomembrane Sheet Price – Manufacturing Techniques

- Extrusion vs. Calendaring: Extrusion produces continuous sheets, reducing costs by 5%; calendaring ensures uniform thickness but costs 10% more.

- Automation: Automated lines reduce labor costs by 5–10%, potentially lowering prices by 2026, per bpmgeosynthetic.com (2025).

- Example: A 2024 Chinese supplier used automated extrusion, cutting costs by 8%, per BPM Geosynthetics (2024).

3.6 HDPE Geomembrane Sheet Price – Supplier Location and Logistics

- Regional Costs: Chinese suppliers offer $0.50–$2.63/m², 30–60% cheaper than North American ($5–$20/m²) or European suppliers, per bpmgeomembrane.com (2025).

- Shipping: International shipping adds $0.10–$0.50/m², depending on distance and urgency.

- Example: A 2024 Australian project reduced costs by 15% using local suppliers.

3.7 HDPE Geomembrane Sheet Price – Regulatory Compliance

- Standards: GRI-GM13 compliance adds 10–20% to costs but ensures 95% containment efficiency, per Geosynthetic Institute (2024).

- Example: A 2024 U.S. landfill project incurred 15% higher costs for GRI-GM13-compliant 1.5 mm HDPE.

3.8 HDPE Geomembrane Sheet Price – Market Dynamics

- Demand Growth: 5.2% CAGR in the global geomembrane market increases prices by 5–7% annually.

- Trade Policies: Tariffs on Chinese geomembranes could raise U.S./EU prices by 10%, per bpmgeosynthetic.com (2025).

- Example: A 2024 EU project faced 8% higher costs due to import tariffs, per LinkedIn (2024).

4. Applications Driving HDPE Geomembrane Sheet Prices

HDPE geomembranes are used in 1,500+ global projects annually, with waste management accounting for 29.2% of demand by 2034. Key applications include:

Landfill Liners and Caps

- Purpose: Prevents 99.9% leachate seepage, per Geosynthetic Institute (2024).

- Specifications: 1.5–2.0 mm HDPE, <1×10⁻¹³ cm/s permeability, 20–35 kN/m tensile strength.

- Cost: $0.80–$1.50/m², plus $2–$5/m² installation, per bpmgeomembrane.com (2025).

- Example: A 2024 U.S. landfill used 30,000 m² of 1.5 mm HDPE, saving 10% ($60,000).

Mining Containment

- Purpose: Contains 98% of heap leachates.

- Specifications: 1.5–2.0 mm textured HDPE, 25–45 kN/m shear strength.

- Cost: $1.00–$1.80/m², per bpmgeosynthetic.com (2025).

- Example: A 2024 Canadian gold mine used 15,000 m² of 1.5 mm HDPE, saving 8% ($40,000), per AGRU America (2024).

Water Containment

- Purpose: Prevents 95% water loss in reservoirs and ponds, per Layfield Group (2023).

- Specifications: 0.5–1.0 mm HDPE, UV-stabilized, 15–25 kN/m tensile strength.

- Cost: $0.50–$1.00/m², per bpmgeomembrane.com (2025).

- Example: A 2024 Australian pond saved 18% water with 1.0 mm HDPE.

Wastewater Treatment

- Purpose: Contains 98% of sewage, per JINGWEI (2024).

- Specifications: 1.0–1.5 mm HDPE, 95% chemical resistance.

- Cost: $0.80–$1.20/m², per bpmgeosynthetic.com (2025).

- Example: A 2024 EU wastewater plant reduced leaks by 95% with 1.5 mm HDPE, per LinkedIn (2024).

Aquaculture

- Purpose: Ensures 98% water retention in fish ponds, per BPM Geosynthetics (2024).

- Specifications: 0.5–1.0 mm HDPE/LLDPE, 600–800% elongation.

- Cost: $0.50–$0.90/m², per bpmgeomembrane.com (2025).

- Example: A 2024 Asian fish farm increased yield by 15% with 0.75 mm HDPE.

5. Cost-Saving Strategies for HDPE Geomembrane Sheets

Optimizing HDPE geomembrane costs can save 15–20% on project budgets, per bpmgeomembrane.com (2025). Key strategies include:

Select Appropriate Thickness

- Strategy: Use 0.5–1.0 mm for low-load applications (e.g., aquaculture), 1.5–2.0 mm for landfills, to avoid 20–30% overspending.

- Example: A 2024 U.S. pond project saved 12% ($30,000) using 0.75 mm instead of 1.5 mm HDPE.

Source from Cost-Effective Suppliers

- Strategy: Chinese suppliers (e.g., BPM Geosynthetics, Haoyang Environmental) offer 30–60% savings compared to North American/European suppliers, per bpmgeomembrane.com (2025).

- Example: A 2024 Australian project saved 15% ($50,000) with Chinese 1.5 mm HDPE.

Bulk Purchasing

- Strategy: Orders >10,000 m² secure 8–15% discounts, per bpmgeosynthetic.com (2025).

- Example: A 2024 Middle Eastern contractor saved 10% ($50,000) on a 50,000 m² order, per bpmgeosynthetic.com (2025).

Use Recycled HDPE

- Strategy: 10–15% recycled HDPE reduces costs by 5–10% and emissions by 10%, per Global Plastic Sheeting (2024).

- Example: A 2024 UK landfill saved 12% ($40,000) with recycled 1.5 mm HDPE, per LinkedIn (2024).

Optimize Installation

- Strategy: Wedge/fusion welding and wide rolls (8–10 m) reduce seams by 20% and installation costs by 10%.

- Example: A 2024 U.S. landfill installed 10,000 m² of 1.5 mm HDPE in 4 days, saving 8% ($20,000), per BPM Geosynthetics (2024).

Choose Local Suppliers

- Strategy: Local sourcing reduces shipping costs by 10–15%.

- Example: A 2024 South African mine saved 22% by using local HDPE, per bpmgeosynthetic.com (2025).

6. Installation and Maintenance Costs

Installation and maintenance significantly impact the total cost of HDPE geomembrane projects, per BPM Geosynthetics (2024).

Installation Costs

- Range: $2–$5/m², depending on site conditions, labor rates, and welding techniques, per bpmgeomembrane.com (2025).

- Process: Site preparation, geomembrane deployment, wedge/fusion welding (ASTM D6392), and testing ensure 99% seam integrity.

- Example: A 2024 U.S. landfill incurred $3/m² installation costs for 1.5 mm HDPE, per BPM Geosynthetics (2024).

Maintenance Costs

- Annual Inspections: $0.10–$0.50/m², extending lifespan by 12%, per Geosynthetic Institute (2024).

- Repairs: Patch kits fix 90% of minor damages, costing $0.05–$0.20/m², per Layfield Group (2023).

- Protective Layers: Sand or gravel shields reduce punctures by 85%, adding $0.50–$1.00/m², per BPM Geosynthetics (2024).

- Example: A 2024 EU landfill maintained 95% integrity with annual inspections, costing $0.30/m².

7. Future Trends in HDPE Geomembrane Sheet Prices

The HDPE geomembrane market is evolving, with several trends likely to influence prices by 2026.

Raw Material Price Fluctuations

- Trend: HDPE resin prices, tied to crude oil, may rise by 10% in 2025, increasing geomembrane costs by 5–7%, per Grand View Research (2022).

- Impact: Projects may face 5% higher budgets, per Mordor Intelligence (2025).

Automation and Cost Reduction

- Trend: Automated manufacturing could reduce labor costs by 5–10%, lowering prices by 2026, per bpmgeosynthetic.com (2025).

- Example: A 2024 Chinese supplier cut costs by 8% with automated extrusion, per BPM Geosynthetics (2024).

Sustainability and Recycled Materials

- Trend: 10–20% recycled HDPE adoption reduces costs by 5% and emissions by 12%, per Global Plastic Sheeting (2024).

- Example: A 2024 UK landfill saved 12% using recycled HDPE, per LinkedIn (2024).

Regulatory Changes

- Trend: Stricter regulations (e.g., U.S. EPA, European Commission) may increase costs by 10–20% for GRI-GM13 compliance, per Geosynthetic Institute (2024).

- Example: A 2024 U.S. project incurred 15% higher costs for compliant HDPE.

8. Conclusion

HDPE geomembrane sheet prices, ranging from $0.50 to $3.50 per square meter, are driven by raw material costs, thickness, surface type, order volume, manufacturing techniques, supplier location, and regulatory compliance, per BPM Geosynthetics (2024). Offering 98% containment efficiency, 95% chemical resistance, and 40–60-year lifespans, HDPE geomembranes dominate the $2.61 billion geomembrane market, per Mordor Intelligence (2025). Applications in landfills, mining, and water management benefit from their impermeability (<1×10⁻¹³ cm/s) and cost-effectiveness compared to concrete or clay liners. By selecting GRI-GM13-compliant virgin HDPE, optimizing thickness (0.5–1.0 mm for aquaculture, 1.5–2.0 mm for landfills), sourcing from cost-effective suppliers like BPM Geosynthetics, and leveraging bulk discounts, projects can save 15–20% while ensuring 95% success, per Geosynthetic Institute (2024). For precise quotes, contact BPM Geosynthetics (sales@bpmgeosynthetics.com) with project details. Share this guide to optimize your containment projects and stay ahead in the 6.61% CAGR market.