Geomembrane liner is a special material used in civil engineering and environmental engineering. It is a film-like polymer material, usually made of plastics such as polyethylene (PE) or polypropylene (PP). Geomembrane liner has high physical strength and chemical stability, and can play a role in waterproofing, anti-seepage, and anti-corrosion in the soil. Geomembrane lienrs are widely used in water conservancy projects, highway and railway projects, port and terminal projects, environmental projects, landfills, mining projects and other fields. It plays an important role in protection and enhancement in these projects, improving the safety and reliability of the project.

BPM Geosynthetics specializes in providing high-quality geomembrane liner with custom size and thickness in bulk order at competitive factory prices. We’ll explore geomembrane liner definition, types, functions, applications, and more.

1. What Is Geomembrane Liner?

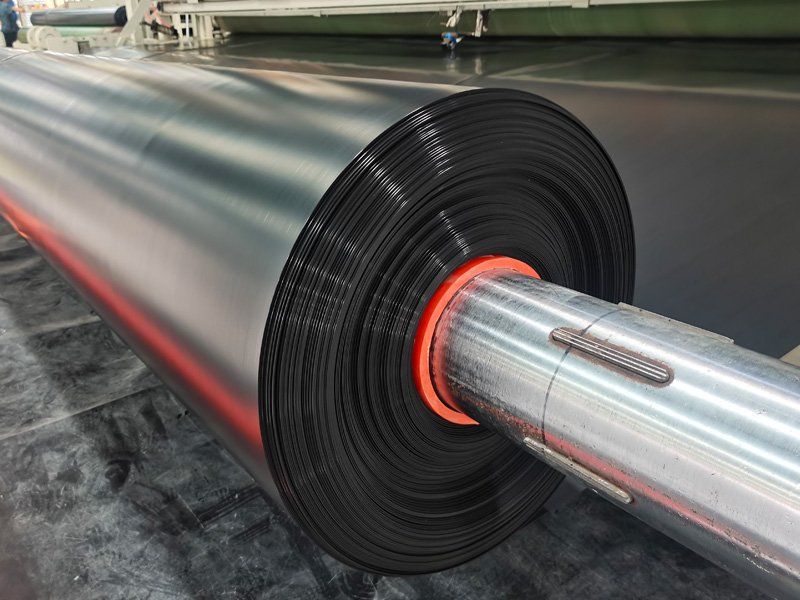

A geomembrane liner is a versatile material extensively used in construction, environmental protection, and water management projects. It is particularly favored in regions that prioritize water resources, such as South Africa. This specialized material serves various applications, including waterproofing, erosion control, and waste management.

Geomembrane liners are thin and flexible materials that are manufactured in controlled environments, typically in factories. They can be classified as either permeable or impermeable. Impermeable geomembrane liners are commonly employed as water barriers in hydropower structures, while permeable liners allow seepage water to pass through without displacing the soil.

These liners are made of waterproof membranes crafted from flexible and durable plastic materials like polyethylene, polypropylene, or PVC. Their exceptional strength and chemical resistance make them well-suited for preventing water leakage, controlling erosion, storing waste, and undertaking environmental protection projects.

Geomembrane liners are renowned for their durability, flexibility, and ability to withstand chemicals and temperature changes, rendering them suitable for diverse environments. By preventing soil and groundwater contamination and acting as a barrier against harmful vapors, geomembrane liners play a vital role in protecting the environment and human health.

2. What Are Types of Geomembrane Liner?

There are various types of geomembrane liners that can be classified based on their composition and function.

2.1 Classification by Ingredient Composition

- Polyethylene Geomembrane (HDPE): Made of polyethylene, these liners have high physical strength and chemical resistance.

- Polypropylene Geomembrane (PP): Made of polypropylene, these liners exhibit good chemical resistance and mechanical properties.

- Polyvinyl Chloride Geomembrane (PVC): Made of polyvinyl chloride, these liners offer good waterproofing and weather resistance.

2.2 Classification by Function

- Waterproof Geomembrane: Primarily used to prevent moisture penetration, these liners find applications in water conservancy projects, underground structures, and more.

- Isolation Geomembrane: Used to separate and isolate soil layers or materials with different properties, preventing them from mixing or infiltrating.

- Reinforced Geomembrane: These liners possess high tensile strength and shear resistance, making them suitable for soil reinforcement and engineering enhancement.

The most commonly used geomembranes in many applications are polyethylene geomembranes and polyvinyl chloride geomembranes.

4. What Are Differences of HDPE vs LDPE vs LLDPE Geomembrane Liner?

The high-density polyethylene geomembranes (HDPE), low-density polyethylene geomembranes (LDPE) and linear low-density polyethylene geomembranes (LLDPE) we use each have their own characteristics and properties, which are inseparable from the performance of the raw materials. , the characteristics of raw materials determine that polyethylene geomembranes play different roles in different application environments.

4.1 HDPE Geomembrane Liner

HDPE is non-toxic, tasteless and odorless, with a density of 0.940~0.976g/cm3. It is a product of polymerization under low pressure conditions under the catalysis of Ziegler catalyst, so high-density polyethylene also becomes low-pressure polyethylene.

HDPE is a highly crystalline, non-polar thermoplastic resin produced by the copolymerization of ethylene. The appearance of original HDPE is milky white, and it is translucent to a certain extent in thin sections. It has excellent resistance to most domestic and industrial chemicals. It can resist the corrosion and dissolution of strong oxidants (concentrated nitric acid), acid and alkali salts and organic solvents (carbon tetrachloride). The polymer is non-hygroscopic and has good waterproof vapor properties, and can be used for moisture-proof and seepage-proof purposes.

The disadvantage is that its aging resistance and environmental stress cracking resistance are not as good as those of LDPE. In particular, thermal oxidation will reduce its performance. Therefore, antioxidants and ultraviolet absorbers are added to high-density polyethylene when making plastic coils to improve its performance. shortcomings.

4.2 LDPE Geomembrane Liner

LDPE is non-toxic, tasteless and odorless, with a density of 0.910~0.940g/cm3. It is polymerized under high pressure of 100~300MPa using oxygen or organic peroxide as a catalyst, and also becomes high-pressure polyethylene.

Low density polyethylene is the lightest variety among polyethylene resins. Compared with high-density polyethylene, its crystallinity (55% ~ 65%) and softening point (90 ~ 100℃) are lower; it has good softness, extensibility, transparency, cold resistance and processability; its chemical It has good stability and can resist acid, alkali and salt aqueous solutions; it has good electrical insulation and breathability; it has low water absorption; it is easy to burn. It is soft in nature and has good extensibility, electrical insulation, chemical stability, processing performance and low temperature resistance (can withstand -70℃).

The disadvantage is that its mechanical strength, moisture barrier, gas barrier and solvent resistance are poor. The molecular structure is not regular enough, the crystallinity (55%-65%) is low, and the crystallization melting point (108-126°C) is also low. Its mechanical strength is lower than that of high-density polyethylene, and its anti-seepage coefficient, heat resistance and anti-sunlight aging resistance are poor. It is easy to age and decompose and discolor under sunlight or high temperature, resulting in a decrease in performance. Therefore, low-density polyethylene is used when making plastic rolls. Antioxidants and UV absorbers are added to improve its deficiencies.

4.3 LLDPE Geomembrane Liner

LLDPE is non-toxic, tasteless and odorless, with a density between 0.915 and 0.935g/cm3. It is made of ethylene and a small amount of higher α-olefins (such as butene-1, hexene-1, octene-1, tetramethylpentene -1, etc.) is a copolymer formed by high-pressure or low-pressure polymerization under the action of a catalyst. The molecular structure of conventional LLDPE is characterized by its linear main chain, with only a small amount or no long branches, but contains some short branches. The absence of long chain branches makes the polymer more crystalline.

Compared with LDPE, LLDPE has the advantages of high strength, good toughness, strong rigidity, heat resistance, and cold resistance. It also has good resistance to environmental stress cracking, tear strength, and resistance to acids, alkalis, organic solvents, etc.

The above three materials play important tasks in different types of anti-seepage projects. HDPE, LDPE and LLDPE all have good insulation, moisture-proof and anti-seepage properties. Their non-toxic, tasteless and odorless properties make them extremely suitable for use in agriculture, aquaculture, artificial lakes, reservoirs and rivers. It is widely used and has been vigorously promoted and popularized by the Fisheries Bureau of the Ministry of Agriculture of China, the Shanghai Academy of Fishery Sciences, and the Fishery Machinery and Instrument Research Institute.

In the medium environment of strong acid, strong alkali, strong oxidant and organic solvent, the material properties of HDPE and LLDPE can be well exerted and utilized, especially the properties of HDPE in resistance to strong acid, strong alkali, strong oxidation and resistance to organic solvents. In terms of performance, it is much higher than the other two materials, so HDPE anti-seepage and anti-corrosion membranes have been fully utilized in the chemical industry and environmental protection industries.

Low-density polyethylene also has good acid, alkali and salt solution resistance, and has good extensibility, electrical insulation, chemical stability, processing performance and low temperature resistance. Therefore, it is widely used in agriculture, aquaculture, packaging, especially low-temperature packaging and cable materials.

4.4 Performance Comparision of Geomembrane Liner

| 1 | Material Performance | High-density polyethylene(HDPE) | Low-density polyethylene(LDPE) | Linear low density polyethylene(LLDPE) |

| 2 | Odor, toxicity | Non-toxic, tasteless and odorless | Non-toxic, tasteless and odorless | Non-toxic, tasteless and odorless |

| 3 | Density | 0.940~0.976g/cm3 | 0.910~0.94g/cm3 | 0.915~0.935g/cm3 |

| 4 | Crystallinity | 85~65% | 45~65% | 55~65% |

| 5 | Molecular Structure | Contains only carbon-carbon and carbon-hydrogen bonds, which require more energy to break | Polymers have smaller molecular weight and require less energy to break | Linear structure, fewer branches and short chains, requiring less energy to break |

| 6 | Softening Point | 125~135℃ | 90~100℃ | 94~108℃ |

| 7 | Mechanical behavior | High strength, good toughness, strong rigidity | Poor mechanical strength | High strength, good toughness, strong rigidity |

| 8 | Tensile Strength | High | Low | Relatively high |

| 9 | Elongation at break | Relatively high | Low | High |

| 10 | Impact strength | Relatively high | Low | High |

| 11 | Moisture-proof and waterproof performance | Good permeability to water, water vapor and air, low water absorption, and good anti-permeability | Poor moisture and air barrier properties | Good permeability to water, water vapor and air, low water absorption, and good anti-permeability |

| 12 | Acid, alkali, corrosion, organic solvent resistance | Resistant to strong oxidant corrosion: resistant to acid, alkali and various salt corrosion: insoluble in any organic solvents, etc. | Resistant to acid, alkali, salt solution and corrosion, but poor solvent resistance | Resistant to acids, alkalis, and organic solvents |

| 13 | Heat/cold resistant | It has good heat resistance and cold resistance, even at normal temperature and even at low temperatures of -40F. It has excellent impact resistance and its low temperature embrittlement temperature is <-90℃. | Low heat attachment performance, low temperature embrittlement temperature < -70℃ | Good heat resistance and cold resistance, low temperature embrittlement temperature <-90℃ |

5. What Are Advantages of Geomembrane Liner?

Geomembrane liners offer several advantages that make them a preferred choice in various applications. Here are the advantages of polyethylene geomembranes:

5.1 Excellent Chemical Resistance

Geomembrane liners exhibit exceptional resistance to corrosion, making them suitable for applications involving chemical exposure.

5.2 Outstanding Stress Cracking Resistance

These Geomembrane liners have high resistance to environmental stress cracking, ensuring their durability and longevity in challenging conditions.

5.3 Lowest Permeability

Geomembranes have very low permeability, making them effective barriers against moisture and gas penetration.

5.4 Excellent UV Resistance

These geomembranes possess excellent resistance to UV radiation, ensuring long-term performance and stability in outdoor environments.

5.5 Stable Low-Temperature Embrittlement Resistance

Geomembranes maintain their flexibility and integrity even in low-temperature conditions, reducing the risk of embrittlement.

5.6 Environmentally Friendly

Geomembrane liners do not contain chemical additives and do not undergo heat treatment, making them an environmentally friendly building material.

5.7 Versatility

Geomembrane liners have good mechanical properties, water permeability, and resistance to corrosion and aging, making them suitable for a wide range of applications.

5.8 Geotechnical Reinforcement

Geomembrane liner have a fluffy structure, good drainage performance, and excellent friction coefficient and tensile strength, providing geotechnical reinforcement properties.

5.9 Adaptability

Geomembrane liners can adapt to uneven base layers, resist damage caused by external construction forces, and exhibit minimal creep over time.

6. Summary

Geomembrane liners find extensive utilization in various fields, including water conservancy projects, highway and railway projects, port and terminal projects, environmental projects, landfills, mining projects, and more. They contribute significantly to the protection and enhancement of these projects, ultimately improving their safety and reliability. Among the different types of geomembranes available, polyethylene geomembranes and polyvinyl chloride geomembranes are the most commonly used in numerous applications. The selection of the appropriate geomembrane type depends on the specific requirements of the project, allowing the project party to choose accordingly to ensure the project’s needs are met.

If you have any further questions or inquiries, please feel free to contact us.