Geogrid is an essential geosynthetic material utilized for soil reinforcement and similar applications. It plays a crucial role in enhancing the performance and effectiveness of various geotechnical projects, setting it apart from other geosynthetic materials. Geogrids are commonly employed as reinforcement elements for reinforced soil structures or as a strengthening mechanism for composite materials. They offer unique capabilities and properties that contribute to the overall stability, durability, and load-bearing capacity of the engineered structures.

As the leading geogrid manufacturer and supplier, BPM Geosynthetics offers geogrid in custom size at best factory price. In this article, let us explore the definition, features and applications of geogrid from the manufacturer’s view.

1. What Is Geogrid?

Geogrid is a geosynthetic material composed of a grid-like structure made from polymers such as polypropylene, polyester, or HDPE. It is used in civil engineering and construction projects to reinforce and stabilize soils and fill materials. Geogrids have high tensile strength and stiffness, distributing loads effectively and preventing soil movement and deformation. They come in different configurations, including square, rectangular, or triangular apertures, and can be uniaxial or biaxial.

Geogrids play a vital role in improving soil stability, preventing erosion, and enhancing the overall structural integrity of various geotechnical applications. They are commonly employed in reinforcing retaining walls, slopes, embankments, roadways, parking lots, and other structures. By providing increased tensile strength and confinement, geogrids contribute to the long-term performance and durability of geotechnical projects, reducing maintenance needs and extending the service life of the structures.

2. What Are Benefits Of Geogrid?

Geogrids offer several benefits in geotechnical and civil engineering applications. Here are some key advantages of using geogrids:

2.1 Enhanced Soil Stability

Geogrids reinforce soils by providing them with increased tensile strength and stiffness. This reinforcement effectively prevents soil deformation, settlement, and lateral movement, improving overall stability and load-bearing capacity.

2.2 High Strength

It has high strength, small creep, adapts to various environmental soils, and can fully meet the use of tall retaining walls in high-grade highways.

2.3 Improved Bearing Capacity

By efficiently distributing loads, geogrids enhance the bearing capacity of weak or poorly compacted soils. This allows for the construction of structures on challenging soil conditions without the need for extensive soil excavation or replacement.

2.4 Stability Foundation

It can effectively improve the interlocking and interlocking effects of the reinforced bearing surface, greatly enhance the bearing capacity of the foundation, effectively restrain the lateral displacement of the soil, and enhance the stability of the foundation.

2.5 Cost-Effectiveness

Utilizing geogrids can result in cost savings during construction projects. They allow for the use of locally available or lower-quality fill materials, reducing the reliance on expensive imported materials. Geogrids also minimize excavation and soil replacement requirements, saving both time and resources.

2.6 Easy Installation

Geogrids are lightweight and easy to handle, simplifying the installation process. They can be quickly rolled out, positioned, and secured, minimizing labor and installation time.

2.7 Long-Term Performance

It is more suitable for deep-sea operations and embankment reinforcement, and fundamentally solves the technical problems of low strength, poor corrosion resistance, and short service life caused by long-term erosion of seawater by gabions made of other materials. They exhibit excellent resistance to degradation, ensuring long-term structural integrity and performance.

3. What Are Types of Geogrid?

Geogrids can be classified into different types based on their material composition, aperture configuration, and reinforcement characteristics. Here are some common types of geogrids:

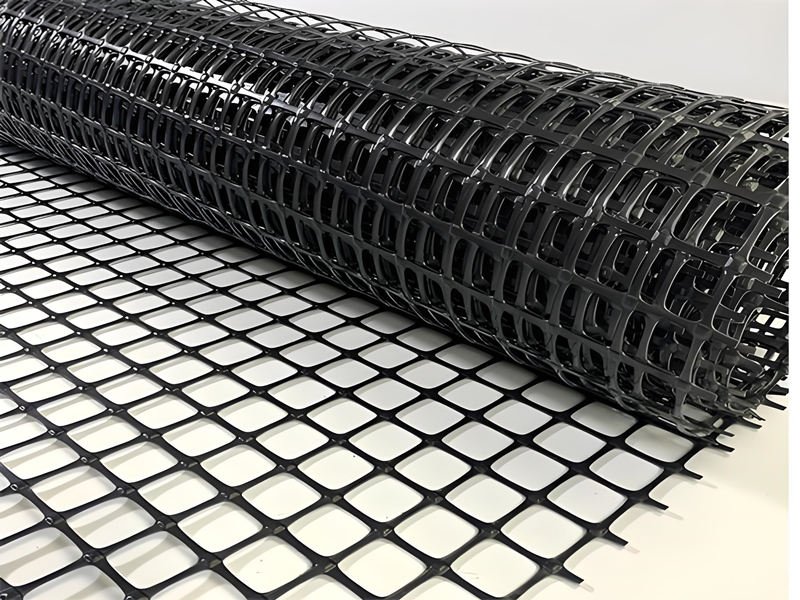

3.1 Plastic Geogrids

The plastic geogrid is stretched to form a square or rectangular polymer mesh, which can be either unidirectional or bidirectional depending on the stretching direction during manufacture. It punches holes in extruded polymer sheets (the raw materials are mostly polypropylene or high-density polyethylene), and then performs directional stretching under heating conditions. One-way stretch grating is only made by stretching along the length direction of the plate; two-way stretch grating is made by continuing to stretch the one-way stretched grating in the direction perpendicular to its length.

3.2 Steel Plastic Geogrid

Steel-plastic geogrid is made of high-strength steel wire (or other fibers), which is specially treated with polyethylene (PE) and other additives, and is extruded into a composite high-strength tensile strip with a rough surface. pattern, it is a high-strength reinforced geotechnical belt. From this single belt, weaved or sandwiched at a certain distance vertically and horizontally, and formed by welding the intersection points using special fusion welding technology to strengthen bonding, it is a reinforced geogrid.

3.3 Fiberglass Geogrid

Fiberglass geogrid is a mesh structure material made of glass fiber using a certain weaving process. In order to protect the glass fiber and improve the overall performance, it is a geocomposite material that has undergone a special coating process. The main component of glass fiber is: silicon oxide, which is an inorganic material. Its physical and chemical properties are extremely stable, and it has high strength, high modulus, high wear resistance and excellent cold resistance, no long-term creep; thermal stability It has good performance; the network structure enables the aggregates to be interlocked and restricted; it improves the load-bearing capacity of the asphalt mixture. Because the surface is coated with special modified asphalt, it has dual composite properties, which greatly improves the wear resistance and shearing capacity of the geogrid.

3.4 Polyester Fiber Warp Knitted Geogrid

Polyester fiber warp-knitted geogrid uses high-strength polyester fiber as raw material. Using a warp-knitted directional structure, the warp and weft yarns in the fabric are not bent to each other. The intersection points are bundled with high-strength fiber filaments to form a strong bonding point and give full play to its mechanical properties. High-strength polyester fiber warp-knitted geogrid The grid has high tensile strength, low elongation force, high tear resistance, small vertical and horizontal strength difference, UV aging resistance, wear resistance, corrosion resistance, light weight, strong interlocking force with soil or gravel, and is good for reinforcing soil Shear resistance and reinforcement play a significant role in improving the integrity and load capacity of the soil.

4. What Are Differences of Plastic vs Steel Plastic vs Fiberglass vs Polyester Warp Knitted Polyester Geogrids?

Geogrids can be categorized into plastic, steel, fiberglass, and polyester warp knitted polyester types, each with distinct characteristics.

Plastic geogrids, made from materials like polypropylene or HDPE, offer high tensile strength, stiffness, and chemical resistance, making them suitable for soil stabilization and retaining walls. Steel geogrids, composed of interconnected steel wires or strips, provide exceptional load-bearing capacity and are commonly used in heavy-duty applications such as pavements and mining. Fiberglass geogrids feature woven or knitted fiberglass yarns, offering high strength, resistance to degradation, and stability, making them ideal for road construction and asphalt overlays. Polyester warp knitted polyester geogrids, knitted with high-strength polyester yarns, provide excellent tensile strength, stiffness, and minimal creep, often utilized in soil reinforcement and slope stabilization projects.

5. What Is Geogrid Used For?

Geogrids are used in various geotechnical and civil engineering applications for soil reinforcement, stabilization, and enhancement of structural integrity. Here are some common uses of geogrids:

5.1 Retaining Walls

Geogrids are used to reinforce and stabilize retaining walls, preventing soil movement and maintaining structural stability. By providing tensile strength to the soil, geogrids distribute loads and reduce the risk of wall failure.

5.2 Slope Stabilization

Geogrids are employed to stabilize slopes and embankments, particularly in areas prone to erosion or landslides. By reinforcing the soil and increasing its strength, geogrids prevent slope failure and ensure slope stability.

5.3 Road Construction

Geogrids are incorporated into roads, highways, and pavements to enhance performance and durability. They distribute loads, minimize rutting and cracking, and improve the overall structural integrity of the road surface.

5.4 Soil Stabilization

Geogrids are used for stabilizing weak or poorly compacted soils, improving their load-bearing capacity and reducing settlement. This allows for construction on challenging soil conditions without extensive soil excavation or replacement.

5.5 Erosion Control

Geogrids are employed in erosion control applications such as riverbanks, shorelines, and steep slopes. They prevent soil erosion and surface instability by providing reinforcement and confinement, effectively protecting against the erosive forces of water flow.

5.6 Landfills

Geogrids are used in landfill construction to enhance stability and integrity of waste containment systems. They reinforce liner and cap systems, minimizing the potential for soil movement or failure.

5.7 Mining

Geogrids find application in mining projects for haul road construction, load support in mining pits, and reinforcement of tailings dams. They improve the load-bearing capacity of the soil and enhance the stability of mining infrastructure.

6. How To Construct And Install Geogrid?

Geogrid installation involves several steps to ensure proper placement and integration with the soil or other materials. Here is a general overview of the geogrid installation process:

6.1 Construction site

It is required to be compacted, flat and level, with sharp protrusions removed.

6.2 Grid Laying

On a flat and compacted site, the main stress direction (longitudinal) of the grating installed and laid should be perpendicular to the axis of the embankment. The laying should be smooth, without wrinkles, and tensioned as much as possible. Fix it with nails and earth and stone weight. The main stress direction of the laid grid is preferably the whole length without joints.

6.3 Selection of Fillers

Fillers should be selected according to design requirements. Practice has proved that all materials except frozen soil, swamp soil, domestic garbage, chalk soil and diatomaceous earth can be used as filler. However, gravel soil and sand soil have stable mechanical properties and are little affected by moisture content, so they should be used first.

6.4 Paving and Compacting of Filler

After the grid is laid and positioned, it should be filled with soil and covered in time. The exposure time should not exceed 48 hours. The flow operation method of backfilling while laying can also be adopted. First spread the filler at both ends, secure the grating, and then advance to the middle. The order of rolling is first on both sides and then in the middle. During rolling, the rollers should not be in direct contact with the reinforcements. Vehicles are generally not allowed to drive on uncompacted reinforcements to avoid dislocation of the reinforcements.

6.5 Anti Drainage Measures

In reinforced soil projects, drainage treatment inside and outside the wall must be done well; foot protection must be done to prevent erosion; filtering and drainage measures must be set up in the soil body. If necessary, geotextiles and permeable tube (or blind ditch). Drainage should be channeled and cannot be blocked, otherwise hidden dangers may occur.

7. Summary

BBPM Geogrids play a vital role in reinforcing and stabilizing soil structures. Their construction methods and materials vary depending on the specific application requirements. Geogrids offer diverse benefits, including increased stability, improved load-bearing capacity, erosion control, and enhanced durability. By providing effective soil reinforcement solutions, geogrids contribute to the successful completion of a wide range of civil and geotechnical engineering projects.

Any questions, please contact us.