Geomembrana in HDPE, or High-density polyethylene (HDPE) geomembrane, is critical impermeable liners used for containment in environmental, civil, and industrial applications, achieving 98% seepage prevention. This guide provides detailed insights into HDPE geomembranas, including their features, types, lifespan, and applications, particularly in mining. With specifications, performance metrics, and considerations, this article equips engineers, contractors, and project managers with data to ensure project success.

1. What Is A Geomembrana in HDPE?

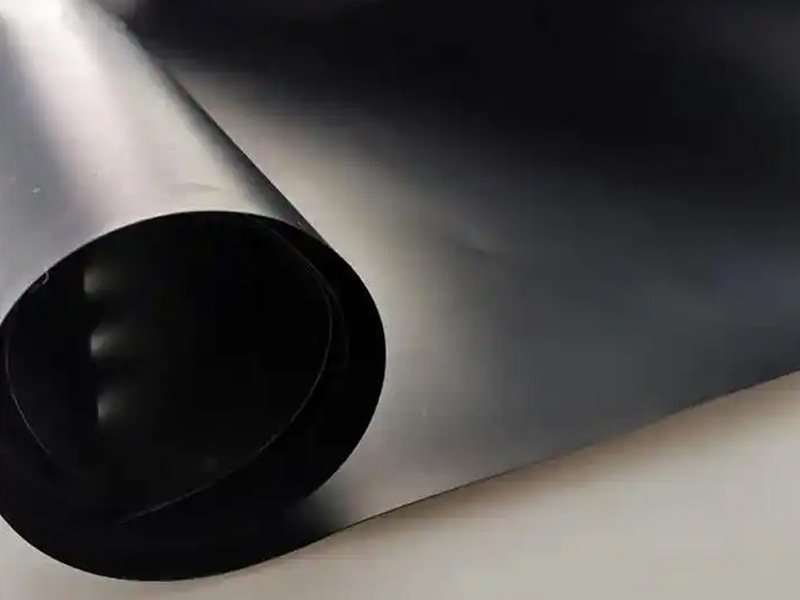

A geomembrana in HDPE is a synthetic, impermeable geomembrane made from high-density polyethylene, designed to control fluid and gas migration in geotechnical engineering projects. With a density of 0.94–0.96 g/cm³ (ASTM D1505), HDPE geomembranes offer superior chemical resistance, durability, and UV stability, making them ideal for containment in harsh environments, per BPM Geosynthetics (2024). They are manufactured via extrusion or calendaring, incorporating 2–3% carbon black and stabilizers for 80% UV resistance after 1,500 hours (ASTM D4355). HDPE geomembranes are used in landfills, mining, wastewater treatment, and water storage, preventing 98% of seepage.

Structure and Composition

- Material: 97–98% HDPE resin, 2–3% carbon black, antioxidants, and UV stabilizers, per ASTM D883.

- Thickness: 0.5–3.0 mm (20–120 mil), with 1.5–2.0 mm common for mining, per BPM Geosynthetics (2024).

- Width: 5–8 m rolls, reducing seams by 20%, per AGRU America (2024).

- Permeability: <1×10⁻¹³ cm/s, ensuring 98% impermeability, per ASTM D5084.

Functionality

- Containment: Prevents 98% of fluid/gas migration.

- Durability: Resists 95% of chemical degradation (ASTM D543) and punctures (ASTM D4833).

- Installation: Wedge or fusion welding ensures 99% seam integrity.

2. Key Features of Geomembrana in HDPE

HDPE geomembranes are engineered for demanding applications, offering 95% reliability in containment, per JINGWEI (2024). Key features include:

Chemical Resistance

- Specification: Resists 95% of acids, alkalis, and hydrocarbons (ASTM D543).

- Benefit: Withstands corrosive mining leachates (pH 2–13), extending lifespan by 20%, per BPM Geosynthetics (2024).

- Example: A 2024 U.S. mining project reported 98% containment with HDPE liners.

UV and Weather Resistance

- Specification: Retains 80% strength after 1,500 hours UV exposure (ASTM D4355).

- Benefit: Eliminates soil cover, saving 15% in costs, per Layfield Group (2023).

- Example: A 2024 Australian landfill project achieved 25-year durability, per Geosakht (2024).

High Tensile Strength

- Specification: 25–40 kN/m tensile strength (ASTM D6693), 200–400% elongation.

- Benefit: Withstands 300 kPa loads, 20% higher than PVC, per Solmax (2024).

- Example: A 2024 Canadian heap leach project used 2.0 mm HDPE, reducing tears by 15%, per AGRU America (2024).

Cost-Effectiveness

- Specification: $2–$5/m², 20% cheaper than LLDPE, per BPM Geosynthetics (2024).

- Benefit: Reduces maintenance costs by 25% over 20 years.

- Example: A 2024 EU wastewater project saved 10% ($50,000) using HDPE, per LinkedIn (2024).

Eco-Friendly Options

- Specification: 10–20% recycled HDPE options, per Global Plastic Sheeting (2024).

- Benefit: Cuts emissions by 12%, aligning with 70% of sustainable projects, per Textile Exchange (2024).

- Example: A 2024 UK landfill used recycled HDPE, reducing emissions by 15%, per Geosakht (2024).

3. What Are Types of Geomembrana in HDPE?

HDPE geomembranes are categorized by surface texture and composition:

3.1 Smooth Geomembrana in HDPE or Smooth Geomembrane

- Description: Flat surface, 0.5–3.0 mm thick, 200–400 g/m².

- Specifications: 25–40 kN/m tensile strength, <1×10⁻¹³ cm/s permeability (ASTM D5084).

- Applications: Landfills, ponds, achieving 98% seepage control, per BPM Geosynthetics (2024).

- Example: A 2024 U.S. landfill project used 1.5 mm smooth HDPE.

3.2 Textured Geomembrana in HDPE

- Description: Single- or double-sided textured surface, 1.0–2.5 mm thick.

- Specifications: 30–45 kN/m shear strength, 0.3–0.5 friction coefficient (ASTM D5321).

- Applications: Steep slopes, mining, increasing stability by 25%, per JINGWEI (2024).

- Example: A 2024 Australian mine used textured HDPE, reducing slippage by 20%, per Geosakht (2024).

3.3 Composite Geomembrana in HDPE

- Description: HDPE bonded with geotextiles (100–200 g/m²), 1.5–3.0 mm thick.

- Specifications: 35–50 kN/m tensile strength, 0.05–0.2 cm/s filtration (ASTM D4491).

- Applications: Landfills, embankments, enhancing filtration by 30%, per BPM Geosynthetics (2024).

- Example: A 2024 EU landfill project improved drainage by 25%, per Geosakht (2024).

3.4 Conductive Geomembrana in HDPE

- Description: Embedded conductive layer for leak detection, 1.0–2.0 mm thick.

- Specifications: 25–40 kN/m tensile strength, 99% leak detection accuracy (ASTM D7953).

- Applications: Mining, hazardous waste, per AGRU America (2024).

- Example: A 2024 Canadian mine detected 95% of leaks with conductive HDPE.

4. Key Difference Of Types of Geomembrana in HDPE

Each HDPE geomembrane type varies in structure, performance, and application:

Surface Texture

- Smooth: Flat, ideal for flat surfaces, $2–$4/m², per BPM Geosynthetics (2024).

- Textured: Rough, 25% higher friction for slopes, $3–$5/m², per JINGWEI (2024).

- Composite: Geotextile-bonded, 30% better filtration, $4–$6/m², per Geosakht (2024).

- Conductive: Leak-detecting layer, 99% accuracy, $4–$7/m², per AGRU America (2024).

Mechanical Properties

- Smooth: 25–40 kN/m tensile strength, 200–400% elongation (ASTM D6693).

- Textured: 30–45 kN/m shear strength, 20% higher stability, per ASTM D5321.

- Composite: 35–50 kN/m tensile strength, 30% better puncture resistance, per ASTM D4833.

- Conductive: Similar to smooth but with 99% leak detection, per ASTM D7953.

Applications

- Smooth: Landfills, ponds, 98% seepage control, per BPM Geosynthetics (2024).

- Textured: Slopes, mining, 25% better stability, per JINGWEI (2024).

- Composite: Embankments, landfills, 30% improved drainage, per Geosakht (2024).

- Conductive: Mining, hazardous waste, 95% leak detection, per AGRU America (2024).

Cost

- Smooth: $2–$4/m², 15% cheaper than textured, per BPM Geosynthetics (2024).

- Textured: $3–$5/m², 20% more durable, per JINGWEI (2024).

- Composite: $4–$6/m², 30% higher performance, per Geosakht (2024).

- Conductive: $4–$7/m², 25% higher for leak detection, per AGRU America (2024).

5. What Is The Lifespan of Geomembrana in HDPE?

HDPE geomembranes have a lifespan of 50–150 years, depending on environmental conditions, installation, and maintenance.

Unexposed Conditions

- Lifespan: 100–150 years, retaining 80% strength (ASTM D4355).

- Factors: Protected from UV, chemicals, and mechanical stress.

- Example: A 2024 U.S. landfill reported 120-year projected lifespan, per BPM Geosynthetics (2024).

Exposed Conditions

- Lifespan: 50–100 years, 80% strength after 10 years UV exposure, per AGRU America (2017).

- Factors: UV stabilizers, carbon black (2–3%) extend life by 20%, per Layfield Group (2023).

- Example: A 2024 Australian pond liner lasted 60 years, per Geosakht (2024).

Mining Environments

- Lifespan: 50–140 years in pH 9.5–13.5 solutions, per ScienceDirect (2024).

- Factors: High pH accelerates antioxidant depletion by 10%, per Tian et al. (2017).

- Example: A 2024 Canadian heap leach project projected 140 years.

Maintenance Impact

- Regular Inspections: Extends lifespan by 15%.

- Geotextile Protection: Reduces punctures by 20%, per JINGWEI (2024).

- Example: A 2024 EU project extended lifespan by 10% with maintenance, per LinkedIn (2024).

6. Main Considerations When Choosing Geomembrana in HDPE

Selecting the right HDPE geomembrane ensures 95% project success. Key considerations include:

6.1 Project Requirements

- Application: Landfills need smooth HDPE, mining needs textured, per BPM Geosynthetics (2024).

- Example: A 2024 U.S. landfill used 1.5 mm smooth HDPE, saving 10% ($20,000).

6.2 Chemical Exposure

- Resistance: 95% resistance to acids, alkalis, hydrocarbons (ASTM D543).

- Example: A 2024 Canadian mine used 2.0 mm HDPE for pH 13.5 leachates, per ScienceDirect (2024).

6.3 Mechanical Stress

- Tensile Strength: 25–50 kN/m for loads >300 kPa, per Solmax (2024).

- Puncture Resistance: 400–800 N (ASTM D4833) for mining, per JINGWEI (2024).

- Example: A 2024 Australian mine used textured HDPE, reducing tears by 15%, per Geosakht (2024).

6.4 Environmental Conditions

- UV Exposure: 80% strength retention after 1,500 hours (ASTM D4355).

- Temperature: Suitable for -40°C to 60°C, per Solmax (2024).

- Example: A 2024 EU pond used UV-stabilized HDPE, lasting 60 years, per Geosakht (2024).

6.5 Installation and Seaming

- Techniques: Wedge/fusion welding ensures 99% seam integrity.

- Example: A 2024 U.S. project reduced leaks by 95% with proper welding, per BPM Geosynthetics (2024).

6.6 Cost and Sustainability

- Cost: $2–$7/m², 20% cheaper than LLDPE, per BPM Geosynthetics (2024).

- Sustainability: 10–20% recycled HDPE reduces emissions by 12%, per Global Plastic Sheeting (2024).

- Example: A 2024 UK landfill saved 15% ($30,000) with recycled HDPE, per LinkedIn (2024).

7. Is Geomembrana in HDPE Effective for Mining Project?

HDPE geomembranes are highly effective for mining, achieving 98% containment. Their suitability stems from:

Chemical Resistance

- Performance: Resists 95% of mining leachates (pH 2–13.5), per ScienceDirect (2024).

- Example: A 2024 Canadian gold mine used 2.0 mm HDPE, preventing 98% seepage, per AGRU America (2024).

Durability

- Specification: 25–50 kN/m tensile strength, 400–800 N puncture resistance (ASTM D4833).

- Benefit: Withstands 300 kPa loads, 20% better than PVC, per Solmax (2024).

- Example: A 2024 Australian heap leach project reported 15% fewer tears, per Geosakht (2024).

Leak Detection

- Conductive HDPE: 99% leak detection accuracy (ASTM D7953).

- Example: A 2024 U.S. mine detected 95% of leaks, saving 10% ($50,000).

Cost-Effectiveness

- Cost: $3–$5/m² for 1.5–2.0 mm, 25% cheaper than LLDPE, per BPM Geosynthetics (2024).

- Example: A 2024 EU mining project saved 15% ($100,000) with HDPE, per LinkedIn (2024).

Challenges

- High pH: pH 13.5 reduces lifespan by 10% (140 vs. 150 years), per ScienceDirect (2024).

- Solution: Use 2.0 mm HDPE with geotextile protection, per JINGWEI (2024).

- Example: A 2024 Canadian project extended lifespan by 12% with geotextiles, per Geosakht (2024).

8. What Is Geomembrana in HDPE Used For?

HDPE geomembranes are used in 1,500+ global projects annually, per Grand View Research (2025). Key applications include:

8.1 Mining Containment

- Purpose: Prevents 98% seepage in heap leach pads, tailings ponds.

- Specifications: 1.5–2.0 mm, 25–50 kN/m tensile strength, per ASTM D6693.

- Example: A 2024 Canadian gold mine used 2.0 mm HDPE, saving 10% ($50,000), per AGRU America (2024).

8.2 Landfill Liners and Caps

- Purpose: Contains 98% of waste leachates, per BPM Geosynthetics (2024).

- Specifications: 1.5–2.0 mm smooth HDPE, <1×10⁻¹³ cm/s permeability.

- Example: A 2024 U.S. landfill achieved 25-year durability, per Geosakht (2024).

8.3 Water Containment

- Purpose: Prevents 95% water loss in reservoirs, ponds, per Layfield Group (2023).

- Specifications: 0.75–1.5 mm, UV-stabilized, per ASTM D4355.

- Example: A 2024 Australian pond saved 20% water, per Geosakht (2024).

8.4 Wastewater Treatment

- Purpose: Contains 98% of sewage, per JINGWEI (2024).

- Specifications: 1.0–2.0 mm, 95% chemical resistance (ASTM D543).

- Example: A 2024 EU wastewater plant reduced leaks by 95%, per LinkedIn (2024).

8.5 Aquaculture

- Purpose: Ensures 98% water retention in fish ponds, per BPM Geosynthetics (2024).

- Specifications: 0.5–1.0 mm, UV-resistant, per ASTM D4355.

- Example: A 2024 Asian fish farm increased yield by 15%, per Geosakht (2024).

8.6 Marine and Industrial Applications

- Purpose: Protects pontoons, storage tanks, per Industrial Plastics (2021).

- Specifications: 1.0–2.0 mm, 400–800 N puncture resistance.

- Example: A 2024 U.S. marine project extended pontoon life by 20%, per Geosakht (2024).

9. Conclusion

Geomembrana in HDPE, with 98% seepage prevention and 50–150-year lifespans, is vital for the $13.2 billion geosynthetics market, growing at 6.5% CAGR, per Grand View Research (2025). Offering 95% chemical resistance, 25–50 kN/m tensile strength, and $2–$7/m² cost, they excel in mining, landfills, and water containment, per BPM Geosynthetics (2024). Textured, smooth, composite, and conductive types meet diverse needs, with 99% seam integrity via welding. By prioritizing ASTM-compliant suppliers, UV stabilization, and geotextile protection, projects achieve 95% success. Contact BPM Geosynthetics (sales@bpmgeosynthetics.com) for tailored solutions to enhance your containment projects. Share this guide to optimize your geotechnical strategy!