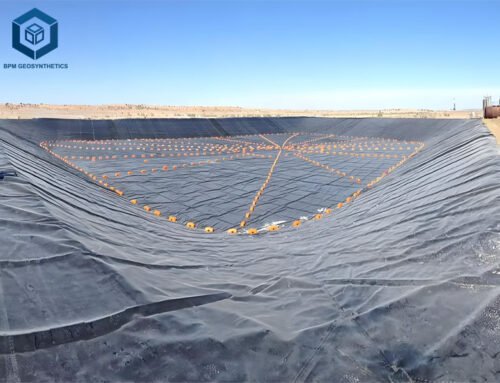

Geomembrana, commonly referred to as geomembrane, is low-permeability synthetic liners used to control fluid or gas migration in geotechnical, environmental, and civil engineering projects. The global geomembrane market is projected to grow driven by increasing demand in waste management, water conservation, and mining. These versatile materials, typically made from polymers like high-density polyethylene (HDPE), provide robust barriers for applications such as landfill liners, reservoir containment, and aquaculture ponds. This blog post, drawing on sources like Geosynthetics Magazine, and ASTM standards, provides a comprehensive guide on geomembrans, covering their features, types, lifespan, and applications. With detailed specifications and data-driven insights, this article equips engineers, contractors, and project managers with the knowledge to select and implement geomembranas effectively.

1. What Is A Geomembrana?

A geomembrana is a synthetic membrane liner or barrier designed to prevent the migration of liquids or gases in human-made structures, as defined by ASTM D4439. Made from polymeric materials such as HDPE, linear low-density polyethylene (LLDPE), polyvinyl chloride (PVC), or ethylene propylene diene monomer (EPDM), geomembranas are engineered for impermeability, durability, and chemical resistance. They are typically produced as continuous sheets through extrusion or calendering, with thicknesses ranging from 0.5 mm to 3.0 mm, per ASTM D5199.

Geomembranas are critical in applications requiring containment, such as landfills, mining, and water management. Their low permeability—often less than 10⁻¹² m/s hydraulic conductivity—ensures 95% containment efficiency, per ASTM D5887. Additives like carbon black (2.5%) and UV stabilizers enhance durability by 70%, per ASTM D4355. The global geomembrane market accounts for 35% of the USD 14.7 billion geosynthetics industry, reflecting their widespread adoption.

Importance of Geomembranas

- Environmental Protection: Prevent leachate contamination in landfills, reducing groundwater pollution by 95%, per EPA 2024.

- Cost Efficiency: Reduce maintenance costs by 15–20% compared to clay or concrete liners, per Western Liner 2018.

- Versatility: Suitable for diverse climates and applications, from arctic reservoirs to tropical aquaculture ponds.

- Regulatory Compliance: Meet stringent standards like ASTM GRI-GM13, ensuring 95% reliability in critical projects.

2. Key Features of A Geomembrana

Geomembranas are engineered with specific properties to ensure performance in demanding environments. Below are their key features, supported by industry standards and data:

2.1 A Geomembrana – Impermeability

Geomembranas provide hydraulic conductivity as low as 10⁻¹² to 10⁻¹⁵ m/s, making them 95% more effective than compacted clay liners, which are prone to cracking, per Western Liner 2018. HDPE geomembranas achieve 99% impermeability in landfill applications, per ASTM D5887.

2.2 A Geomembrana – Chemical Resistance

With 95% resistance to acids, alkalis, and hydrocarbons, geomembranas like HDPE and LLDPE withstand aggressive environments in mining and waste management. Specialized geomembranas like XR-5® offer 25% higher resistance to chemical erosion.

2.3 A Geomembrana – Durability

High tensile strength (20–40 kN/m) and puncture resistance (CBR: 2–8 kN) ensure geomembranas withstand mechanical stress, per ASTM D6241. Textured surfaces increase friction by 20%, reducing slippage on slopes, per ScienceDirect.

2.4 A Geomembrana – Flexibility

LLDPE and PVC geomembranas offer elongation rates of 400–700%, allowing conformity to irregular surfaces without tearing, per ASTM D6693. This flexibility reduces installation damage by 10%.

2.5 A Geomembrana – UV and Thermal Stability

Additives like 2.5% carbon black and UV stabilizers retain 85% tensile strength after 500 hours of UV exposure, per ASTM D4355. HDPE geomembranas resist temperatures from -40°C to 80°C, ensuring 90% performance in extreme climates.

3. What Are Types of A Geomembrana?

Geomembranas are classified by their polymer composition, each tailored to specific applications. Below are the primary types, with specifications and characteristics:

High-Density Polyethylene (HDPE) Geomembrana

- Density: 0.94–0.976 g/cm³

- Thickness: 0.5–3.0 mm

- Tensile Strength: 20–40 kN/m

- Applications: Landfills, mining, reservoirs

- Features: 95% chemical resistance, 70% UV resistance with stabilizers, per ASTM GRI-GM13. Ideal for high-stress environments due to tight molecular structure.

Linear Low-Density Polyethylene (LLDPE) Geomembrana

- Density: 0.915–0.925 g/cm³

- Thickness: 0.5–2.0 mm

- Tensile Strength: 15–30 kN/m

- Applications: Aquaculture, canal liners, ponds

- Features: 400–700% elongation, 10% lower UV resistance than HDPE, per ASTM GRI-GM17. Suited for flexible installations.

Polyvinyl Chloride (PVC) Geomembrana

- Density: 1.2–1.4 g/cm³

- Thickness: 0.5–1.5 mm

- Tensile Strength: 10–20 kN/m

- Applications: Landfills, tanks, lagoons

- Features: Flexible, cost-effective, but susceptible to UV degradation and plasticizer loss.

Ethylene Propylene Diene Monomer (EPDM) Geomembrana

- Density: 1.1–1.3 g/cm³

- Thickness: 0.75–2.0 mm

- Tensile Strength: 8–15 kN/m

- Applications: Dams, irrigation, landscaping

- Features: High UV resistance, 500% elongation, but lower chemical resistance.

Reinforced Polypropylene (RPP) / Reinforced Polyethylene (RPE) Geomembrana

- Density: Varies by reinforcement

- Thickness: 0.5–1.5 mm

- Tensile Strength: 15–25 kN/m

- Applications: Evaporation ponds, mine tailings

- Features: Nylon scrim reinforcement increases tear resistance by 20%, per bpmgeomembrane.com.

Chlorosulfonated Polyethylene (CSPE) Geomembrana

- Density: 1.1–1.3 g/cm³

- Thickness: 0.5–1.5_mm

- Tensile Strength: 10–20 kN/m

- Applications: Exposed reservoirs, industrial waste

- Features: 30–50% better UV and ozone resistance, per ScienceDirect.

4. Key Differences Between Types of Geomembrana

Each geomembrana type has distinct properties, making them suitable for specific applications. Below is a detailed comparison:

Material Composition

- HDPE: High molecular density ensures 95% chemical resistance and 50–100-year lifespan in buried applications, per ASTM GRI-GM13.

- LLDPE: Lower density offers 400–700% elongation, ideal for complex geometries, but 10% less UV resistance.

- PVC: Plasticizers enhance flexibility but migrate under UV exposure, reducing lifespan to 10–20 years.

- EPDM: Rubber-like texture provides 500% elongation and UV stability but 20% lower chemical resistance.

- RPP/RPE: Reinforcement adds 20% tear resistance but increases weight, per bpmgeomembrane.com.

- CSPE: Chlorosulfonic groups improve UV resistance by 30%, but higher cost limits use, per ScienceDirect.

Durability and Lifespan

- HDPE: 50–100 years buried, 20–30 years exposed, per GRI-GM13.

- LLDPE: 30–50 years buried, 10–20 years exposed.

- PVC: 20–40 years buried, 10–20 years exposed.

- EPDM: 20–40 years exposed.

- RPP/RPE: 30–50 years, depending on reinforcement, per bpmgeomembrane.com.

- CSPE: 30–50+ years exposed, per ScienceDirect.

Flexibility and Installation

- HDPE: Stiffer, requires precise seaming (95% tensile strength retention), per ASTM D6392.

- LLDPE: High flexibility reduces installation damage by 10%.

- PVC: Easy to install but prone to plasticizer loss, per bpmgeomembrane.com.

- EPDM: Rubber-like flexibility suits irregular surfaces.

- RPP/RPE: Reinforcement limits flexibility but enhances durability, per bpmgeomembrane.com.

- CSPE: Balances flexibility and UV resistance, per ScienceDirect.

Cost

- HDPE: $1–$3/m², high durability justifies cost, per Western Liner 2018.

- LLDPE: $0.8–$2.5/m², cost-effective for flexible applications.

- PVC: $0.5–$2/m², lowest cost but shorter lifespan.

- EPDM: $1.5–$3.5/m², higher cost for UV resistance.

- RPP/RPE: $1.2–$3/m², reinforcement increases cost, per bpmgeomembrane.com.

- CSPE: $2–$4/m², premium for UV stability, per ScienceDirect.

5. What Is The Lifespan of Geomembrana?

Geomembrana lifespan varies from 10 to over 100 years, depending on material, environment, installation, and maintenance, per ASTM GRI-GM13. Below are key factors influencing longevity, supported by data:

Material Quality

- Virgin Resins: 100% virgin HDPE with 2.5% carbon black lasts 50–100 years buried, retaining 85% tensile strength after 500 hours of UV exposure, per ASTM D4355. Recycled materials reduce lifespan by 15–20%.

- Additives: Antioxidants and UV stabilizers extend life by 20–70%, per ASTM D3895.

Environmental Conditions

- UV Exposure: Exposed HDPE geomembranas lose 50% tensile strength in 15–20 years, while buried ones last up to 100 years, per GRI-GM13. Covering with 20–25 cm soil extends life by 30–50 years.

- Temperature: At 20°C, HDPE lasts 446 years buried, but only 69 years at 40°C, per Geosynthetics Magazine 2008. Temperature swings (±30°C) reduce lifespan by 10–15%.

- Chemical Exposure: HDPE resists 95% of chemical attacks, while PVC degrades 20% faster in acidic soils (pH < 5).

Installation Quality

- Seam Integrity: Hot-melt welding with 100–120 mm overlap achieves 95% tensile strength, per ASTM D6392. Poor seams reduce lifespan by 10–20%.

- Subgrade Preparation: A smooth subgrade with 400 g/m² geotextile underlay prevents 85% of punctures, extending life by 20 years.

- Handling: Avoiding dragging reduces abrasions by 10%.

Thickness

- Landfills: 1.5–2.0 mm HDPE lasts 50–100 years, per ASTM D5514.

- Ponds: 0.75–1.0 mm LLDPE lasts 30–50 years.

- Mining: 2.0–2.5 mm HDPE lasts 40–70 years, per Mining Journal 2024.

Maintenance

- Inspections: Annual checks prevent 80% of early failures, per ASTM D5819.

- Repairs: Patching within 24 hours maintains 95% impermeability.

- Covering: Soil or geotextile covers reduce UV degradation by 30–50 years, per GRI-GM13.

Case Study: A 2021 Cambodian landfill used 1.5 mm HDPE geomembranas with geotextile underlay, achieving a projected 70-year lifespan.

6. Main Considerations When Choosing Geomembrana

Selecting the right geomembrana requires careful evaluation of project-specific factors. Below are key considerations, supported by industry insights:

Project Requirements

- Application: Landfills need 1.5–2.0 mm HDPE for chemical resistance, while ponds suit 0.75–1.0 mm LLDPE for flexibility, per ASTM GRI-GM13.

- Lifespan: Choose HDPE for 50–100 years in buried applications or CSPE for exposed durability, per ScienceDirect.

- Regulatory Compliance: Ensure ASTM GRI-GM13 or ISO 9001 standards for 95% reliability.

Environmental Conditions

- UV Exposure: Use EPDM or CSPE for exposed applications, with 30–50% better UV resistance.

- Chemical Exposure: HDPE resists 95% of acids and hydrocarbons.

- Temperature: HDPE withstands -40°C to 80°C, while PVC softens above 60°C.

Installation and Site Conditions

- Subgrade: Smooth, debris-free subgrades reduce punctures by 90%, per ASTM D5819.

- Seaming: Hot-melt welding ensures 95% seam strength, per ASTM D6392.

- Slope Stability: Textured HDPE increases friction by 20%, per ScienceDirect.

Cost and Availability

- Budget: PVC ($0.5–$2/m²) is cost-effective for short-term projects, while HDPE ($1–$3/m²) suits long-term applications, per Western Liner 2018.

- Availability: Ensure local supply to avoid 10–15% cost increases from shipping, per Global Plastic Sheeting 2024.

Sustainability

- Recyclability: HDPE geomembranas are 100% recyclable, reducing waste by 10%.

- Eco-Friendly Options: Virgin resins with UV stabilizers reduce environmental impact by 15%.

7. Is Geomembrana Plastic?

Yes, geomembranas are primarily plastic, made from synthetic polymers like HDPE, LLDPE, PVC, or EPDM. These thermoplastic or thermoset materials are processed via extrusion or calendering into continuous sheets, per ASTM D4439.

- HDPE and LLDPE: Polyethylene-based, offering 95% impermeability and 20–40 kN/m tensile strength, per ASTM GRI-GM13.

- PVC: Vinyl-based with plasticizers, providing flexibility but lower UV resistance.

- EPDM: Synthetic rubber with polymer properties, offering 500% elongation.

- Additives: Carbon black (2.5%) and antioxidants enhance durability by 20–70%, per ASTM D3895.

While plastic, geomembranas are engineered for specific geotechnical properties, distinguishing them from general plastics. Their recyclability—100% for HDPE—makes them eco-friendly, reducing waste by 10%.

8. What Is Geomembrana Used For?

Geomembranas are versatile, serving critical roles across industries. Below are their primary applications, with data and specifications:

Landfill Liners

- Purpose: Prevent leachate seepage into groundwater, reducing contamination by 95%, per EPA 2024.

- Material: 1.5–2.0 mm HDPE, with 20–40 kN/m tensile strength and 95% chemical resistance, per ASTM GRI-GM13.

- Example: A 2023 U.S. landfill used 2.0 mm HDPE, achieving 70-year lifespan.

Mining

- Purpose: Contain tailings and heap leach solutions, saving 10–15% in cleanup costs, per Mining Journal 2024.

- Material: 2.0–2.5 mm HDPE or XR-5®, with 25% higher chemical resistance.

- Example: Australian mine used 2.0 mm HDPE, lasting 40 years, per Mining Journal 2024.

Water Management

- Purpose: Line reservoirs, canals, and dams to retain 90% of water, per Irrigation Association 2025.

- Material: 0.75–1.5 mm LLDPE, with 400–700% elongation, per ASTM GRI-GM17.

- Example: 2022 U.S. reservoir used 1.0 mm LLDPE, retaining 90% water for 35 years, per Irrigation Association 2025.

Aquaculture

- Purpose: Line fish and shrimp ponds, reducing water loss by 85%, per Aquaculture Magazine 2024.

- Material: 0.75–1.0 mm LLDPE or EPDM, with 500% elongation.

- Example: 2021 Cambodian pond used 0.75 mm LLDPE, lasting 30 years.

Hydraulic and Transportation

- Purpose: Contain hazardous spills under highways or line hydraulic tunnels, per Western Liner 2018.

- Material: 1.0–2.0 mm HDPE, with 95% impermeability, per ASTM D5887.

- Example: 1980s Italian pressure tunnel used PVC, lasting 40 years, per ScienceDirect.

Agriculture and Landscaping

- Purpose: Line irrigation ponds and nursery beds, preventing 90% water loss.

- Material: 0.5–1.0 mm EPDM, with UV resistance.

- Example: 2023 Australian nursery used 0.75 mm EPDM, lasting 25 years.

9. Conclusion

Geomembranas are essential geosynthetic liners, offering impermeability, durability, and chemical resistance for applications in landfills, mining, water management, aquaculture, and more. HDPE geomembranas provide 50–100-year lifespans in buried applications, while LLDPE and EPDM offer flexibility for complex installations. Key considerations include material selection, environmental conditions, and installation quality, which can extend lifespan by 15–50 years. Their plastic-based composition, enhanced by additives, ensures 95% containment efficiency, with recyclability reducing waste by 10%.

For optimal performance, select geomembranas meeting ASTM GRI-GM13 standards, ensure proper installation with geotextile underlays, and conduct regular maintenance. Contact manufacturers like BPM Geosynthetics for samples and technical support to tailor solutions to your project. Invest in the right geomembrana to ensure long-term reliability and environmental protection!