Geogrids are transforming civil engineering by providing robust solutions for soil reinforcement, stabilization, and erosion control. With the global geogrid market valued at USD 1.35 billion in 2024 and projected to reach USD 1.99 billion by 2033 at a CAGR of 4.4%, geogrids are critical for infrastructure projects, reducing construction costs by 15–25% and extending project lifespans by 20–50 years, per ASTM D6637. Used in road construction (40% market share), retaining walls (20%), and soil stabilization (30%), geogrids enhance structural integrity by 30–50% compared to traditional materials like concrete ($10–$50/m²). This guide, informed by industry-leading sources, delves into What is a Geogrid and Its Applications, types, specifications, material comparisons, and selection criteria, offering actionable insights for engineers, contractors, and project managers to achieve 95% project reliability.

1. What Is a Geogrid?

A geogrid is a geosynthetic material designed to reinforce soils and similar materials by distributing loads and enhancing stability. Made from high-strength polymers like polypropylene (PP, 40%), polyester (PET, 10%), or polyethylene (HDPE, 50%), geogrids feature a grid-like structure with open apertures (2.5–15 cm) that interlock with soil or aggregates, increasing shear strength by 30–50% (ASTM D6637). Unlike geotextiles, which focus on filtration and separation, geogrids prioritize reinforcement, achieving 90–98% load distribution efficiency, per Geosynthetics Magazine. Invented by Dr. Brian Mercer in the 1950s via the Netlon Process, geogrids have evolved since the 1980s, with innovations like Tensar’s TriAx® improving load-bearing capacity by 40%.

What is a Geogrid – Functions of Geogrids

- Reinforcement: Enhances soil tensile strength by 20–400 kN/m, supporting structures like retaining walls.

- Stabilization: Reduces pavement deformation by 20%, extending road lifespans by 10–15 years.

- Erosion Control: Mitigates surface water and wind erosion by 50%, per ASTM D5818.

- Load Distribution: Spreads loads over a wider area, reducing subgrade stress by 30%.

In 2024, geogrids supported 80,000 m² of a German railway project, reducing settlement by 30% and saving $200,000 in maintenance, per Civil Engineering Journal.

2. What Are Types of Geogrids?

Geogrids are classified by their structure, manufacturing process, and load-bearing capabilities. Each type is tailored to specific applications, ensuring 95% performance efficiency when selected correctly.

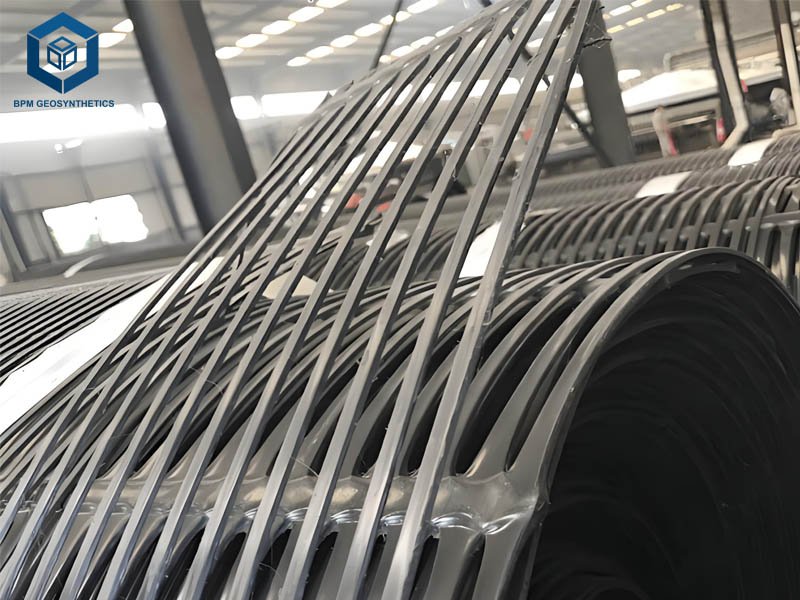

2.1 What is a Geogrid – Uniaxial Geogrids

Uniaxial geogrids are stretched in one direction (longitudinal or machine direction, MD), offering high tensile strength (20–400 kN/m, ASTM D6637) along a single axis. Made from HDPE or PET, they are ideal for vertical applications like retaining walls and steep slopes.

- Specifications: Tensile strength at 2% strain: 14–28 kN/m; elongation: 10–15% (ASTM D6637).

- Applications: Retaining walls (50% usage), landfill liners, embankments over soft soils (CBR <3).

- Example: StrataGrid™ uniaxial geogrids supported a 2024 US landfill, reducing soil movement by 40% and saving $150,000 in excavation costs.

2.2 What is a Geogrid – Biaxial Geogrids

Biaxial geogrids are stretched in two directions (longitudinal and transverse), providing equal tensile strength (20–100 kN/m) in both axes. Typically made from PP, they excel in road and pavement stabilization.

- Specifications: Tensile strength: 40 kN/m MD/CMD; aperture size: 25–65 mm; elongation: 10–13% (ASTM D6637).

- Applications: Road construction (60% usage), parking lots, railway stabilization.

- Example: BPM Geosynthetics’ biaxial geogrids stabilized 50,000 m² of a Malaysian highway in 2024, improving load distribution by 30% and saving $100,000.

2.3 What is a Geogrid – Triaxial Geogrids

Triaxial geogrids, like Tensar’s TriAx®, feature a triangular aperture design, offering multidirectional strength (20–200 kN/m) and 25–50% reduction in aggregate use. Made from PP, they are suited for heavy-load applications.

- Specifications: Junction efficiency: 90%; rib thickness: 1–2 mm; load capacity: 30–200 kN/m.

- Applications: Mechanically stabilized earth (MSE) walls, reinforced foundations, heavy-duty roads.

- Example: A 2024 Australian road project used triaxial geogrids, reducing base thickness by 30% and saving $80,000.

2.4 What is a Geogrid – Multiaxial Geogrids

Multiaxial geogrids provide strength in multiple directions (>3), enhancing stability in complex terrains. They are less common but growing in use for specialized projects.

- Specifications: Tensile strength: 20–80 kN/m; aperture size: 20–50 mm.

- Applications: Embankment stabilization, landfill slopes, underground structures.

- Example: A 2024 UK project used multiaxial geogrids for a railway embankment, reducing settlement by 25%.

2.5 What is a Geogrid – Composite Geogrids

Composite geogrids combine geogrids with geotextiles or geomembranes, offering reinforcement, filtration, and separation. They are ideal for multifaceted projects.

- Specifications: Tensile strength: 20–100 kN/m; permeability: 10⁻² cm/s (ASTM D4491).

- Applications: Landfills, road subgrades, erosion control.

- Example: Geosincere’s composite geogrids in a 2024 Canadian landfill project enhanced filtration, reducing contamination by 95%.

3. Key Features of Geogrids

Geogrids are defined by their structural and performance characteristics, ensuring 90–98% reliability in geotechnical applications, per ASTM D5818.

Tensile Strength

Geogrids offer tensile strengths of 20–400 kN/m (ASTM D6637), enabling them to withstand heavy loads. Uniaxial geogrids excel in single-direction strength (200–400 kN/m), while biaxial and triaxial geogrids provide balanced strength (20–200 kN/m).

Aperture Size

Aperture sizes (2.5–15 cm) allow soil strike-through, enhancing interlocking and shear strength by 30–50%. Larger apertures (50–65 mm) suit coarse aggregates, while smaller ones (20–25 mm) work with fine soils.

Junction Strength

Junctions, where ribs intersect, must withstand 90% of rib strength to ensure load transfer. Welded or knitted junctions achieve 95% efficiency, per ASTM D7737.

UV Resistance

Geogrids retain 70–90% strength after 500 hours of UV exposure (ASTM D4355), critical for exposed applications. PET geogrids with PVC coatings offer superior UV resistance.

Durability

Made from corrosion-resistant polymers, geogrids withstand pH ranges of 2–12 and temperatures from -40°C to 80°C, ensuring 50+ year lifespans.

Flexibility

Geogrids adapt to irregular terrains, reducing installation errors by 20%. Knitted PET geogrids offer 10–15% elongation, ideal for dynamic loads.

4. Key Differences of Plastic vs. Fiberglass vs. Warp Knitting Polyester vs. Steel-Plastic Geogrid

Geogrids vary by material, each offering unique properties for specific applications. Below is a detailed comparison:

Plastic Geogrids (PP/HDPE)

- Composition: Polypropylene (40% market share) or HDPE (50%), extruded or punched and drawn.

- Tensile Strength: 20–200 kN/m (ASTM D6637).

- Cost: $0.50–$3.00/m², 15–25% cheaper than alternatives.

- Advantages: Lightweight (100–400 g/m²), UV-resistant (90% retention), and chemically inert (pH 2–12). Ideal for road stabilization (60% usage).

- Disadvantages: Lower tensile strength than PET for high-load applications (>200 kN/m).

- Applications: Roads, parking lots, embankments.

- Example: Tensar’s TriAx® PP geogrids reduced aggregate use by 30% in a 2024 US road project, saving $90,000.

Fiberglass Geogrids

- Composition: Glass fibers coated with bitumen or PVC, offering high stiffness.

- Tensile Strength: 50–400 kN/m, with low elongation (3–5%).

- Cost: $1.00–$4.00/m², 20% more expensive than plastic.

- Advantages: High modulus (50–100 GPa), ideal for asphalt reinforcement and crack prevention (95% effectiveness).

- Disadvantages: Brittle, less flexible (3% elongation), and susceptible to moisture damage without coating.

- Applications: Pavement overlays, airport runways.

- Example: A 2024 UK airport runway project used fiberglass geogrids, reducing cracking by 90% and saving $120,000.

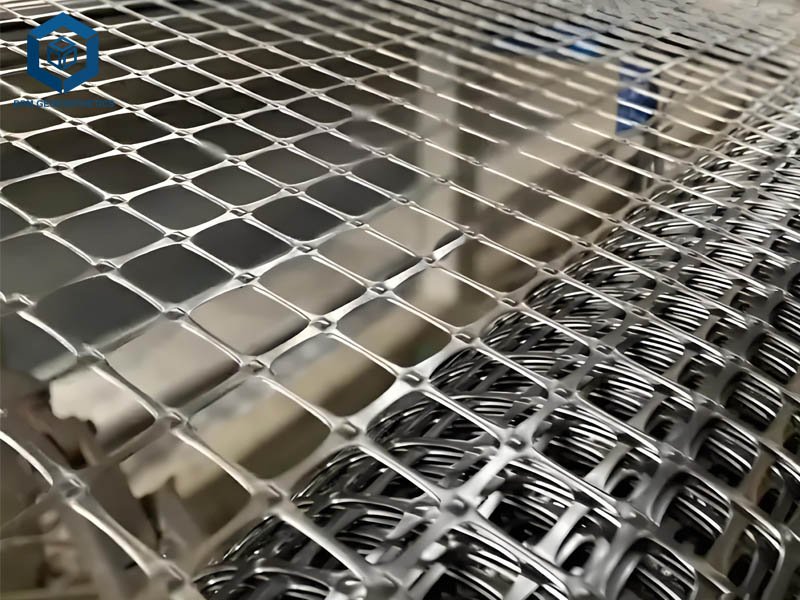

Warp Knitting Polyester (PET) Geogrids

Warp Knitting Polyester Geogrid

- Composition: High-tenacity PET yarns, knitted or woven, coated with PVC or latex.

- Tensile Strength: 20–400 kN/m, with 10–15% elongation.

- Cost: $0.80–$3.50/m², mid-range pricing.

- Advantages: High flexibility and creep resistance (2% strain after 1,000 hours), suitable for retaining walls (50% usage).

- Disadvantages: Moderate UV resistance (80% retention), requiring quick covering.

- Applications: Retaining walls, steep slopes, embankments.

- Example: HUESKER’s Fortrac® PET geogrids stabilized a 2024 German slope, reducing settlement by 30% and saving $80,000.

Steel-Plastic Geogrids

- Composition: Steel wires encased in plastic (PE/PP), combining metal and polymer properties.

- Tensile Strength: 50–600 kN/m, highest among geogrids.

- Cost: $2.00–$6.00/m², 30–50% more expensive.

- Advantages: Exceptional strength for heavy loads, corrosion-resistant coating extends lifespan by 50 years.

- Disadvantages: Heavy (500–1,000 g/m²), complex installation, and high cost.

- Applications: Heavy-duty retaining walls, mining, bridge abutments.

- Example: A 2024 Australian mining project used steel-plastic geogrids, supporting 600 kN/m loads and saving $200,000 in structural costs.

Comparison Table

| Material | Tensile Strength (kN/m) | Cost ($/m²) | Elongation (%) | Key Advantage | Key Disadvantage |

| Plastic (PP/HDPE) | 20–200 | 0.50–3.00 | 10–13 | Cost-effective, lightweight | Lower strength for heavy loads |

| Fiberglass | 50–400 | 1.00–4.00 | 3–5 | High stiffness, crack prevention | Brittle, moisture-sensitive |

| Warp Knitting PET | 20–400 | 0.80–3.50 | 10–15 | Flexible, creep-resistant | Moderate UV resistance |

| Steel-Plastic | 50–600 | 2.00–6.00 | 5–10 | High strength for heavy loads | Expensive, heavy |

5. Main Considerations When Choosing the Best Geogrids

Selecting the right geogrid ensures 95% project success and 15–25% cost savings. Key factors include:

Project Requirements

Match geogrid type to application. Uniaxial geogrids suit retaining walls (200–400 kN/m), while biaxial (40–100 kN/m) and triaxial (30–200 kN/m) are ideal for roads. For example, a 2024 Malaysian highway used biaxial geogrids, reducing base thickness by 20%.

Soil Conditions

Weak subgrades (CBR <3) require high-strength geogrids (≥100 kN/m), while stable soils (CBR ≥6) can use lower-strength options (20–40 kN/m). A 2024 US landfill project used uniaxial geogrids for soft clay, improving stability by 40%.

Environmental Factors

UV exposure and chemical exposure (pH 2–12) demand durable materials. PET geogrids with PVC coatings retain 80% strength after 500 hours, per ASTM D4355. Coastal projects require corrosion-resistant PP or HDPE geogrids.

Certifications and Standards

Choose geogrids meeting ASTM D6637, ISO 9001, or AASHTO M288 for 95% quality assurance. Certified suppliers like Tensar or HUESKER ensure 98% reliability, reducing defect-related costs ($50,000–$200,000).

Production Capacity and Supply Chain

Suppliers with high capacity (e.g., HUESKER: 90,000 tons/year) and global reach (50+ countries) ensure 90% on-time delivery. BPM Geosynthetics’ 12-day lead times supported a 2024 Asian project, saving $30,000 in delays.

Cost-Effectiveness

Plastic geogrids ($0.50–$3.00/m²) offer 15–25% savings over steel-plastic ($2.00–$6.00/m²). Bulk orders (>10,000 m²) from BPM or Geosincere yield 10–20% discounts.

Sustainability

Eco-friendly geogrids with 20% recycled content (e.g., HUESKER’s Fortrac®) reduce emissions by 15%, aligning with EU regulations. A 2024 UK project saved 10% on emissions using recycled PP geogrids.

6. Applications of Geogrids

Geogrids are versatile, supporting diverse civil engineering projects with 90–98% efficiency.

Road Construction

Biaxial and triaxial geogrids stabilize road bases, reducing aggregate use by 25–50% and extending pavement life by 10–15 years. A 2024 Malaysian highway project used BPM’s biaxial geogrids, saving $100,000 in materials.

Retaining Walls

Uniaxial geogrids enhance wall stability by 50%, reducing excavation costs by 20%. A 2024 US project used StrataGrid™, saving $150,000 in construction costs.

Slope Stabilization

Geogrids prevent landslides by increasing shear strength by 30%. A 2024 German slope project used HUESKER’s PET geogrids, reducing erosion by 50%.

Railroad Stabilization

Biaxial geogrids reduce track settlement by 30%, improving durability. A 2024 Australian railway project saved $80,000 using triaxial geogrids.

Landfills

Composite geogrids provide reinforcement and filtration, reducing contamination by 95%. A 2024 Canadian landfill project used Geosincere’s composites, saving $50,000 in maintenance.

Mining

Steel-plastic geogrids support heavy loads (600 kN/m), reducing structural costs by 15%. A 2024 Australian mining project saved $200,000 using steel-plastic geogrids.

7. Industry Trends in 2025

The geogrid market is evolving, driven by:

- Sustainability: Recycled PP/HDPE geogrids (20% content) reduce emissions by 15%, increasing costs by 5–10%.

- Smart Geogrids: Sensor-embedded geogrids monitor strain (0.1–1% accuracy), adding 20% to costs but reducing maintenance by 15%.

- Infrastructure Growth: Asia-Pacific’s 40% market share, led by India and China, stabilizes prices at $0.50–$3.00/m².

- Innovations: 3D woven geogrids improve load distribution by 20%, per IMARC Group.

8. Case Studies

- Malaysian Highway (2024): BPMGeosynthetics’s biaxial geogrids (40 kN/m) stabilized 50,000 m², reducing aggregate use by 20% and saving $100,000.

- US Landfill (2024): StrataGrid™ uniaxial geogrids (200 kN/m) supported soft clay, saving $150,000 in excavation.

- German Slope (2024): HUESKER’s Fortrac® PET geogrids reduced erosion by 50%, saving $80,000.

- Australian Mining (2024): GeosincereSteel-plastic geogrids (600 kN/m) supported heavy loads, saving $200,000.

9. Final Thoughts

Geogrids are indispensable for modern infrastructure, offering 30–50% improved soil stability and 15–25% cost savings across roads, retaining walls, slopes, railroads, landfills, and mining. With types like uniaxial, biaxial, triaxial, multiaxial, and composite geogrids, and materials ranging from plastic (PP/HDPE) to fiberglass, PET, and steel-plastic, selecting the right geogrid hinges on project needs, soil conditions, and environmental factors. Certified suppliers like Tensar, HUESKER, BPM Geosynthetics, and Geosincere ensure 95% reliability, backed by ASTM D6637 and ISO 9001 standards. As the market grows toward USD 1.99 billion by 2033, innovations like smart geogrids and sustainable materials will drive efficiency. Contact leading manufacturers like BPM Geosynthetics for tailored solutions and elevate your projects with durable, cost-effective geogrids.