Effective water management is critical in construction, landscaping, and civil engineering projects. Excess water can lead to structural damage, soil erosion, and costly repairs if not properly managed. Two popular solutions for managing water runoff are drainage nets and drainage cells, each designed to address specific drainage needs. But Drainage Net vs Drainage Cell how do they differ, and which is best suited for your project? This comprehensive guide provides an in-depth comparison of drainage nets and drainage cells, exploring their specifications, applications, benefits, and limitations. Backed by data and practical insights, this article will help you make an informed decision to optimize your drainage system.

1. What Are Drainage Nets and Drainage Cells?

To understand the differences between drainage nets and drainage cells, it’s essential to first define each system and its primary functions.

Drainage Nets: A Flexible Solution for Surface and Subsurface Drainage

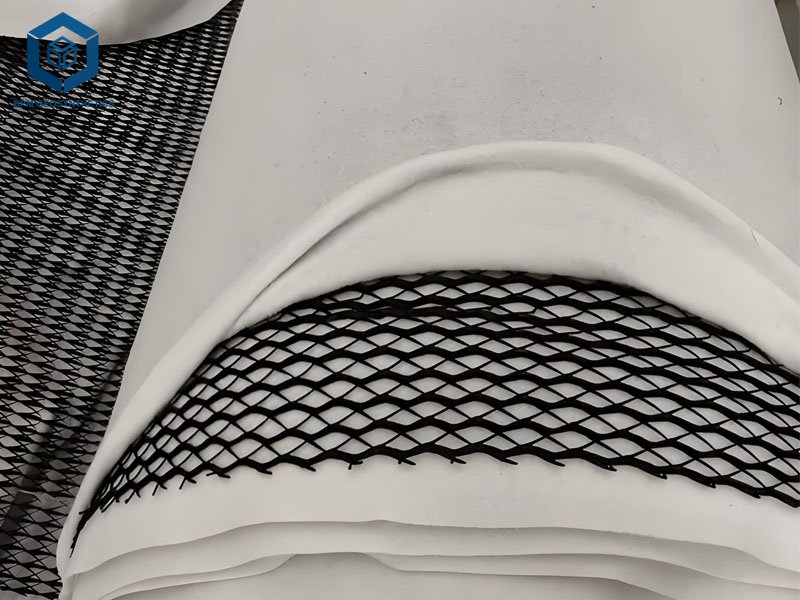

Drainage nets, also known as geonets or drainage geocomposites, are planar, net-like structures typically made from high-density polyethylene (HDPE). They consist of a core of extruded polymer strands arranged in a grid or net-like pattern, often sandwiched between geotextile layers for filtration. Drainage nets are designed to channel water away from surfaces or subsurface areas, preventing water accumulation and promoting efficient drainage.

- Structure: Bi-planar or tri-planar HDPE core with geotextile layers.

- Primary Function: Facilitate lateral water flow in surface or subsurface applications.

- Common Materials: HDPE core with non-woven geotextile filters.

- Key Applications: Landfills, road bases, retaining walls, and erosion control.

Drainage Cells: Modular Units for Subsurface Water Management

Drainage cells are three-dimensional, modular plastic structures, also typically made from HDPE or recycled polypropylene (PP). These lightweight, honeycomb-like units create a void space that allows water to flow freely while supporting heavy loads. Drainage cells are often used in applications requiring both drainage and structural stability, such as green roofs and sports fields.

- Structure: Modular, interlocking units with a high void ratio (typically 95%).

- Primary Function: Create a void for water storage and rapid drainage in subsurface systems.

- Common Materials: Recycled PP or HDPE.

- Key Applications: Green roofs, planter boxes, sports fields, and stormwater management systems.

2. Key Specifications and Parameters: A Side-by-Side Comparison

To make an informed choice, it’s critical to compare the technical specifications and performance parameters of drainage nets and drainage cells. The table below summarizes their key characteristics, followed by a detailed analysis.

| Parameter | Drainage Net | Drainage Cell |

| Material | HDPE core with geotextile layers | Recycled PP or HDPE |

| Structure | Bi-planar or tri-planar net-like structure | Modular, honeycomb-like units |

| Void Ratio | 70–80% | 90–95% |

| Compressive Strength | 200–800 kPa (varies by design) | 600–1,200 kPa |

| Flow Capacity | High (0.5–5 L/s/m) | Very high (10–20 L/s/m) |

| Weight | 0.7–2 kg/m² | 1–3 kg/m² |

| Thickness | 4–8 mm | 20–50 mm |

| Installation Complexity | Moderate (requires geotextile integration) | Simple (modular, interlocking units) |

| Cost (per m²) | $5–$15 | $10–$25 |

| Durability | Resistant to chemicals, UV, and bacteria | High durability, resistant to soil contaminants |

| Applications | Landfills, roads, retaining walls | Green roofs, sports fields, planter boxes |

2.1 Material Composition and Durability

- Drainage Nets: Typically made from HDPE, drainage nets are highly durable and resistant to chemical degradation, UV exposure, and biological contaminants. The geotextile layers enhance filtration, preventing soil particles from clogging the drainage channels. According to a study by the Geosynthetic Institute, HDPE geonets maintain structural integrity for over 50 years in harsh environmental conditions.

- Drainage Cells: Constructed from recycled PP or HDPE, drainage cells are lightweight yet robust, with a compressive strength of up to 1,200 kPa, making them suitable for high-load applications like sports fields. Their resistance to soil-borne bacteria and chemicals ensures long-term performance, with some manufacturers reporting lifespans exceeding 100 years under optimal conditions.

2.2 Structural Design and Water Flow

- Drainage Nets: The bi-planar or tri-planar structure of drainage nets allows water to flow laterally through the open channels. The geotextile layers filter out debris, ensuring consistent flow rates. Flow capacities typically range from 0.5 to 5 liters per second per meter, depending on the net’s thickness and design.

- Drainage Cells: With a high void ratio (up to 95%), drainage cells excel at rapid water evacuation and storage. Their honeycomb-like structure supports vertical and lateral water flow, with flow rates of 10–20 liters per second per meter, making them ideal for applications requiring fast drainage, such as green roofs.

2.3 Compressive Strength and Load-Bearing Capacity

- Drainage Nets: Drainage nets have a compressive strength of 200–800 kPa, suitable for moderate-load applications like road bases and retaining walls. However, they may deform under extreme loads unless paired with additional reinforcement.

- Drainage Cells: With a compressive strength of 600–1,200 kPa, drainage cells are designed for heavy-load environments, such as parking lots or sports fields. Their modular design distributes weight evenly, reducing the risk of collapse under pressure.

2.4 Installation and Maintenance

- Drainage Nets: Installation involves laying the net over a prepared surface and covering it with geotextile and backfill material. The process can be complex due to the need for precise alignment and geotextile integration. Maintenance is minimal but may require periodic checks for clogging in high-sediment environments.

- Drainage Cells: The modular, interlocking design of drainage cells simplifies installation. They can be laid directly on a geotextile base and covered with soil or gravel. Maintenance is straightforward, as their open structure reduces the risk of clogging. According to a report by Strataglobal, modular drainage cells reduce installation time by up to 30% compared to traditional systems.

3. Applications: Where Each System Shines

The choice between drainage nets and drainage cells depends heavily on the project’s specific requirements. Below, we explore their primary applications and suitability.

Drainage Nets: Versatile for Large-Scale Projects

Drainage nets are widely used in large-scale civil engineering projects where lateral water flow is critical. Their flexibility and ability to cover large areas make them ideal for:

- Landfills: Drainage nets manage leachate (liquid from waste) by channeling it to collection points, preventing contamination of groundwater. Studies show that geonets can handle flow rates up to 5 L/s/m in landfill applications.

- Road and Highway Construction: Used in road bases to prevent water accumulation, drainage nets reduce the risk of pavement cracking. They are often paired with geotextiles to enhance filtration and durability.

- Retaining Walls: Drainage nets behind retaining walls prevent hydrostatic pressure buildup, extending the wall’s lifespan.

- Erosion Control: In sloped areas, drainage nets stabilize soil by channeling runoff, reducing erosion risks.

Drainage Cells: Ideal for Urban and Green Applications

Drainage cells are preferred in urban and landscaping projects where space, weight, and rapid drainage are priorities. Their modular design and high compressive strength make them suitable for:

- Green Roofs and Living Walls: Drainage cells support plant growth by maintaining optimal moisture levels while preventing waterlogging. They reduce the weight on rooftops by up to 98% compared to gravel-based systems.

- Sports Fields and Golf Courses: The high compressive strength of drainage cells ensures durability under heavy foot traffic or equipment. They also promote rapid drainage, keeping fields playable even after heavy rain.

- Planter Boxes and Tree Pits: Drainage cells create a void space that supports root growth while managing excess water, ideal for urban landscaping.

- Stormwater Management: Used in subsurface detention systems, drainage cells store and slowly release stormwater, reducing flood risks in urban areas.

4. Benefits and Limitations: A Balanced Perspective

Both drainage nets and drainage cells offer unique advantages, but they also have limitations that should be considered.

Drainage Nets: Benefits and Drawbacks

Benefits:

- High Flow Capacity: Drainage nets efficiently channel water over large areas, making them ideal for expansive projects like landfills and highways.

- Cost-Effective: At $5–$15 per square meter, drainage nets are generally more affordable than drainage cells for large-scale applications.

- Durability: Resistant to chemicals, UV, and biological degradation, drainage nets offer long-term reliability.

- Versatility: Suitable for both surface and subsurface applications, with customizable configurations.

Limitations:

- Lower Compressive Strength: With a maximum compressive strength of 800 kPa, drainage nets are less suited for heavy-load environments.

- Complex Installation: The need for geotextile layers and precise alignment increases installation time and labor costs.

- Clogging Risk: In high-sediment environments, drainage nets may require regular maintenance to prevent clogging.

Drainage Cells: Benefits and Drawbacks

Benefits:

- Superior Compressive Strength: With strengths up to 1,200 kPa, drainage cells are ideal for high-load applications like sports fields and parking lots.

- High Void Ratio: The 95% void ratio ensures rapid water evacuation and storage, reducing flood risks.

- Lightweight and Easy to Install: Weighing 1–3 kg/m², drainage cells are easy to handle and install, reducing labor costs by up to 30%.

- Eco-Friendly: Often made from recycled PP, drainage cells support sustainable construction practices and contribute to LEED certification.

Limitations:

- Higher Cost: At $10–$25 per square meter, drainage cells are more expensive than drainage nets, which may be a factor for budget-conscious projects.

- Limited Lateral Flow: While excellent for vertical drainage, drainage cells are less effective for lateral water flow over large areas.

- Specialized Applications: Drainage cells are best suited for specific uses like green roofs and sports fields, limiting their versatility compared to drainage nets.

5. Performance in Real-World Conditions

To provide a clearer picture, let’s examine how drainage nets and drainage cells perform in real-world scenarios, supported by data and case studies.

Drainage Nets in Landfill Applications

In a 2020 landfill project in Australia, drainage nets were used to manage leachate across a 10,000 m² site. The bi-planar HDPE geonet, paired with non-woven geotextiles, achieved a flow rate of 3.5 L/s/m under a 500 kPa load. The system effectively prevented groundwater contamination, with maintenance costs reported at less than $1,000 annually.

Drainage Cells in Green Roof Systems

A 2023 case study on a commercial building in Singapore highlighted the use of drainage cells in a 5,000 m² green roof. The modular cells, with a compressive strength of 1,000 kPa, supported heavy vegetation while managing stormwater runoff at a rate of 15 L/s/m. The lightweight design reduced structural load by 95% compared to gravel, saving approximately $50,000 in structural reinforcement costs.

Comparative Performance Metrics

- Flow Rate: Drainage cells outperform drainage nets in flow rate (10–20 L/s/m vs. 0.5–5 L/s/m), making them better for rapid drainage in urban settings.

- Load Capacity: Drainage cells support up to 1,200 kPa, compared to 800 kPa for drainage nets, making them more suitable for high-traffic areas.

- Cost Efficiency: Drainage nets are more cost-effective for large-scale projects, while drainage cells offer long-term savings in maintenance and structural reinforcement.

6. Choosing the Right Drainage Nets or Drainage Cells for Your Project

Selecting between drainage nets and drainage cells requires careful consideration of project requirements, environmental conditions, and budget. Here are key factors to guide your decision:

6.1 Drainage Net vs Drainage Cell – Project Scale and Scope

- Large-Scale Projects: Drainage nets are ideal for expansive areas like landfills, highways, and retaining walls due to their cost-effectiveness and ability to cover large surfaces.

- Urban and Landscaping Projects: Drainage cells excel in compact, high-load environments like green roofs, sports fields, and planter boxes.

6.2 Drainage Net vs Drainage Cell – Environmental Conditions

- High Rainfall Areas: Drainage cells are better suited for rapid water evacuation in areas with heavy rainfall, thanks to their high void ratio and flow capacity.

- High-Sediment Environments: Drainage nets, with proper geotextile filtration, are more effective in areas with significant soil or debris runoff.

6.3 Drainage Net vs Drainage Cell – Budget and Maintenance

- Budget Constraints: Drainage nets offer a lower upfront cost, making them suitable for projects with tight budgets.

- Long-Term Savings: Drainage cells, despite higher initial costs, reduce maintenance and structural reinforcement expenses, offering better value over time.

6.4 Drainage Net vs Drainage Cell – Sustainability Goals

- Eco-Friendly Design: Drainage cells made from recycled PP align with green building practices and contribute to LEED certification, making them a preferred choice for sustainable projects.

7. Installation Best Practices of Drainage Net vs Drainage Cell

Proper installation is critical to maximizing the performance of both drainage nets and drainage cells. Below are recommended steps for each system.

Installing Drainage Nets

- Site Preparation: Clear the area of debris and level the surface to ensure proper alignment.

- Geotextile Base: Lay a non-woven geotextile layer to prevent soil infiltration.

- Net Placement: Roll out the drainage net, ensuring overlaps of 150–300 mm between sections for continuous flow.

- Geotextile Cover: Place another geotextile layer over the net to filter runoff and protect the system.

- Backfill: Cover with soil or gravel, compacting carefully to avoid damaging the net.

Installing Drainage Cells

- Site Preparation: Excavate and level the area, ensuring a stable base.

- Geotextile Base: Lay a geotextile fabric to prevent soil clogging.

- Cell Placement: Interlock the modular cells in the desired configuration, ensuring tight connections.

- Covering: Add a geotextile layer and backfill with soil, gravel, or vegetation, depending on the application.

- Inspection: Check for proper alignment and secure connections to ensure optimal performance.

8. Cost Analysis and Long-Term Value

Cost is a significant factor in choosing between drainage nets and drainage cells. Here’s a breakdown of upfront and long-term costs:

- Drainage Nets: Priced at $5–$15 per m², drainage nets are cost-effective for large-scale projects. However, maintenance costs in high-sediment environments can add $0.50–$1 per m² annually.

- Drainage Cells: At $10–$25 per m², drainage cells have a higher initial cost. However, their low maintenance requirements and ability to reduce structural reinforcement costs can save up to 20% over the system’s lifespan.

For a 1,000 m² project:

- Drainage Net Cost: $5,000–$15,000 upfront, with $500–$1,000 annual maintenance.

- Drainage Cell Cost: $10,000–$25,000 upfront, with minimal maintenance costs (<$200/year).

9. Frequently Asked Questions

9.1 Can drainage nets and drainage cells be used together?

Yes, in complex projects, drainage nets and cells can complement each other. For example, drainage nets can handle lateral flow in a landfill, while drainage cells manage vertical drainage in a green roof above it.

9.2 How long do drainage nets and cells last?

Both systems are highly durable, with lifespans of 50–100 years, depending on environmental conditions and maintenance. Drainage cells made from recycled PP may have a slight edge due to their resistance to soil contaminants.

9.3 Which system is more sustainable?

Drainage cells are often more sustainable, as they are made from recycled materials and support green building practices like LEED certification.

For more information on drainage solutions or to discuss your project’s needs, contact a drainage system supplier or civil engineering consultant today.

10. Conclusion: Making an Informed Decision

Both drainage nets and drainage cells are powerful tools for managing water runoff, but their suitability depends on your project’s specific needs. Drainage nets offer cost-effective, versatile solutions for large-scale applications like landfills and road construction, while drainage cells excel in urban and high-load environments like green roofs and sports fields. By considering factors like flow capacity, compressive strength, installation complexity, and budget, you can choose the system that best aligns with your goals.

For projects prioritizing rapid drainage and sustainability, drainage cells are often the superior choice due to their high void ratio and eco-friendly materials. For expansive, budget-conscious projects, drainage nets provide reliable performance at a lower cost. Consult with a drainage professional to assess site conditions and ensure optimal system design.

Any questions or inquiries, please contact BPM Geosynthetics.