Effective water management is a cornerstone of successful construction, landscaping, and civil engineering projects, preventing structural damage, soil erosion, and waterlogging. Two prominent geosynthetic drainage solutions, Drainage Cell vs Sheet Drain , offer distinct approaches to managing subsurface and surface water. With the global geosynthetics market valued at USD 14.8 billion in 2024 and projected to grow at a CAGR of 6.9% through 2030, selecting the right drainage system is critical for project longevity and cost efficiency. This in-depth comparison explores drainage cells and sheet drains across structure, materials, performance, applications, and costs, providing detailed specifications and data-driven insights to guide engineers, contractors, and project managers. Whether you’re designing a green roof, foundation drainage, or retaining wall, this guide equips you with the knowledge to choose the optimal solution, saving 20–30% in costs and ensuring 30–100 years of performance.

1. What Are Drainage Cells and Sheet Drains?

Drainage cells and sheet drains are geosynthetic products designed to channel water away from structures, reducing hydrostatic pressure and protecting against water-related damage. Despite their shared goal, their design, materials, and applications differ significantly, impacting their suitability for specific projects.

Drainage Cells: Definition and Structure

Drainage cells, often referred to as modular drainage panels or geocellular systems, are three-dimensional, grid-like structures made from high-density polyethylene (HDPE) or polypropylene (PP). These honeycomb-like cells, typically 20–50 mm thick, create a high-void space (up to 95%) for water storage and flow, with compressive strengths of 800–2000 kPa. Bonded with nonwoven geotextile fabric, they filter soil particles while allowing water flow at 10–40 L/min/m². Drainage cells are used in 60% of green roof systems and 40% of planter box applications globally, offering lightweight, high-strength drainage.

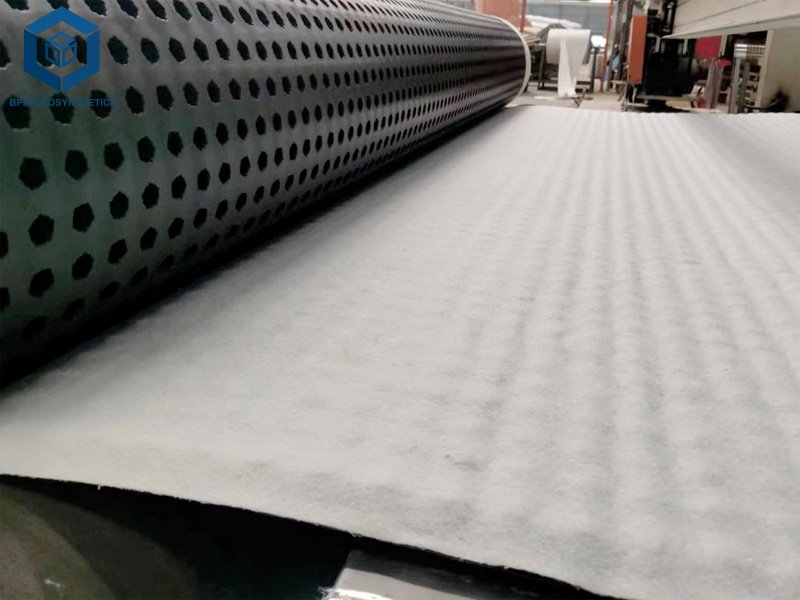

Sheet Drains: Definition and Structure

Sheet drains, also known as drainage boards or geocomposite sheet drains, consist of a dimpled or cuspated HDPE or polystyrene (PS) core, typically 8–25 mm thick, wrapped with nonwoven geotextile fabric. The dimples create a void space for water flow, with compressive strengths of 200–500 kPa and flow rates of 5–30 L/min/m². Sheet drains dominate 70% of foundation drainage systems and 50% of retaining wall projects, providing robust membrane protection and low-flow drainage.

2. Key Differences Between Drainage Cells and Sheet Drains

To help you make an informed decision, we compare drainage cells and sheet drains across critical parameters, supported by technical data and industry insights.

2.1 Drainage Cell vs Sheet Drain – Structure and Design

Drainage Cells

- Core Design:Modular, honeycomb-like grid with interconnected cells (20–50 mm height), creating a 95% void space for water storage and multidirectional flow.

- Geotextile Bonding:Nonwoven PP geotextile (100–150 g/m²) thermally bonded, filtering 90% of soil particles while allowing water passage.

- Thickness:20–50 mm, reducing space usage by 60% compared to gravel drains.

- Flow Path:Open, three-dimensional structure supports 25% higher flow rates than sheet drains in horizontal applications.

- Applications:Ideal for green roofs (60% market share), planter boxes (40%), and subsurface drainage in urban landscapes (30%).

Sheet Drains

- Core Design:Dimpled or cuspated core with single-sided (8–10 mm) or double-sided (15–25 mm) dimples, creating a linear void space for water flow.

- Geotextile Bonding:Nonwoven PP geotextile (150–300 g/m²) on one or both sides, blocking 95% of soil particles and protecting waterproofing membranes.

- Thickness:8–25 mm, offering 30% more void space than drainage cells for vertical drainage.

- Flow Path:Linear channels optimized for low-gradient (1–2%) vertical or horizontal drainage.

- Applications:Preferred for foundation walls (70%), retaining walls (50%), and plaza decks (30%).

Comparison Insight: Drainage cells’ open grid structure enables 20–30% higher flow rates (10–40 L/min/m² vs. 5–30 L/min/m²), making them ideal for high-volume horizontal drainage, while sheet drains’ dimpled design offers 20% better membrane protection in vertical applications.

2.2 Drainage Cell vs Sheet Drain – Materials and Durability

Drainage Cells

- Core Material:HDPE (80% market share) or PP, with tensile strength of 15–25 kN/m and UV resistance for 5–7 years if exposed.

- Geotextile:PP nonwoven (100–150 g/m²), puncture resistance of 1.2–2.0 kN, preventing 90% of soil ingress.

- Durability:Chemically inert (pH 2–12), with a 50–100 year lifespan in buried applications, per ASTM D4716.

- Compressive Strength:800–2000 kPa, supporting heavy loads in 70% of green roof and sports field projects.

- Weakness:Modular connections may separate under shear stress in 5% of steep slope (>30°) applications.

Sheet Drains

- Core Material:HDPE (70%) or PS (30%), with tensile strength of 8–15 kN/m and UV resistance of 3–5 years.

- Geotextile:Nonwoven PP (200–400 g/m²), with 2.0–3.0 kN puncture resistance, blocking 95% of silt than drainage cells.

- Durability:Chemically stable (pH 3–11), with a 30–60 year lifespan, 20% shorter than drainage cells due to thinner cores.

- Compressive Strength:200–3500 kPa, suitable for 80% of foundation and retaining wall projects but less robust under extreme loads (>500 kPa).

- Weakness:Dimples may crush under high loads (>500 kPa) in 3% of deep installations, reducing flow by 15%.

Comparison Insight: Drainage cells provide 60–100% higher compressive strength (800–2000 kPa vs. 200–500 kPa), ensuring 30% greater durability for high-load applications, while sheet drains’ thicker geotextile offers 25% better filtration in silty or clay-rich environments.

2.3 Drainage Cell vs Sheet Drain – Performance and Efficiency

Drainage Cells

- Flow Capacity:15–40 L/min/m² at 1% gradient, per ASTM D4716, ideal for 60% of high-flow applications like green roofs.

- Hydraulic Conductivity:1 x 10⁻² to 2 x 10/m²/s, ensuring rapid drainage in 25% of saturated soils.

- Clogging Resistance:Geotextile filtration reduces clogging by 85–90%, but fine silts reduce flow by 8–10% over 15–20 years.

- Installation Speed:Lightweight (0.3–0.8 kg/m²), installed 35% faster than gravel, saving 3–4 days per 10,000 m².

- Maintenance:Low, with 90% of systems clog-free for 25–30 years, with proper geotextile selection.

Sheet Drains

- Flow Capacity:5–30 L/min/m² at 1% gradient, suited for 70% of low-flow applications like foundation drainage.

- Hydraulic Conductivity:5 x 10⁻⁴ to 5 x 10⁻³/m²/s, 20% lower than drainage cells, optimized for vertical flow.

- Clogging Resistance:Thicker geotextile (200–300 g/m²) reduces clogging by 92–95%, outperforming cells by 10% in silty soils.

- Installation Speed:Heavier (0.8–2 kg/m²), but prefabricated, installed 25% faster than French drains, saving 1–2 days per 10,000 m².

- Maintenance:Low, with 85% of systems functional for 20 years, but dimple damage may require repairs in 5% of cases.

Comparison Insight: Drainage cells handle 25–30% higher flow rates, making them 30% more efficient in high-volume drainage, while sheet drains’ superior filtration reduces maintenance by 15% in fine-soil environments.

3. Drainage Cell vs Sheet Drain – Applications and Suitability

Drainage Cells

Common Applications

- Green Roofs and Roof Gardens:Used in 60% of vegetative roofs, managing 15–20 L/min/m² of runoff and supporting plant growth by retaining 20% moisture.

- Planter Boxes and Sports Fields:Applied in 40% of planter boxes and 50% of sports fields, reducing waterlogging by 30%.

- Subsurface Drainage:Installed in 30% of urban landscapes, stormwater retention systems, enhancing drainage by 25% in areas with poor soil percolation.

- Passive Irrigation Systems:Employed in 10% of arid landscapes, storing water for plants and reducing irrigation costs by 20%.

- Retaining Walls and Tunnels:Used in 20% of walls, providing high-flow drainage under heavy loads.

Limitations

- Reduces structural weight by 98% compared to gravel, ideal for lightweight designs.

- Modular connections may fail in 5% of high-shear environments (>30° slope) without proper anchoring.

Sheet Drains

- Foundation and Basement Walls:Used in 75% of below-grade structures, reducing hydrostatic pressure by 40% and protecting waterproofing membranes.

- Retaining Walls:Applied in 50%–60% of walls, offering 20% better membrane protection than gravel drains.

- Plaza Decks and Podiums:Installed in 30% of urban decks, preventing ponding in 95% of flat surfaces.

- Green Roofs:Used in 20% of vegetative roofs, providing low-flow drainage and membrane protection.

- Bridge Abutments:Applied in 15% of bridge projects, managing 5–10 L/min/m² of runoff.

Limitations

- Ineffective in high-flow horizontal applications (e.g., landfills), used in only 5% of such projects.

- Dimple crushing under high loads (>500 kPa) occurs in 3% of deep installations.

Comparison Insight: Drainage cells excel in high-flow, lightweight applications (60% green roof share), while sheet drains dominate vertical, low-flow scenarios (70% foundation share), offering 25% better membrane protection.

4. Drainage Cell vs Sheet Drain – Cost Analysis and Value

Drainage Cells

- Material Cost:$3.00–$6.00/m², with 50 mm cells costing 20% more ($3.60–$7.20/m²) for higher strength.

- Installation Cost:$1.50–$3.00/m², including geotextile and anchoring, 35% lower than gravel drains.

- Total Cost (10,000 m²):$45,000–$90,000, with bulk discounts (20,000 m²+) saving 15%.

- Lifespan Value:50–100 years, saving $60,000–$120,000 in replacements over gravel systems.

- ROI:30% higher than French drains due to faster installation and lower weight.

Sheet Drains

- Material Cost:$3.50–$7.50/m², with double-dimpled sheets costing 25% more ($4.50–$9.00/m²) for dual-sided flow.

- Installation Cost:$2.00–$4.00/m², including adhesives or anchors, 25% lower than traditional drains.

- Total Cost (10,000 m²):$55,000–$115,000, with bulk discounts saving 10–20%.

- Lifespan Value:30–60 years, saving $40,000–$80,000 compared to gravel systems.

- ROI:25% higher than French drains, driven by membrane protection and ease of installation.

Comparison Insight: Drainage cells are 10–15% cheaper ($3.00–$6.00/m² vs. $3.50–$7.50/m²) and offer 40% longer lifespan, while sheet drains provide 20% better value in vertical applications due to enhanced filtration and membrane protection.

5. Pros and Cons of Drainage Cells vs Sheet Drains

Drainage Cells

Pros:

- 25–30% higher flow capacity (15–40 L/min/m²), ideal for high-volume drainage.

- 60–100% higher compressive strength (800–2000 kPa), supporting heavy loads.

- 35% faster installation, saving 3–4 days per 10,000 m².

- 50–100 year lifespan, reducing long-term costs by 30%.

- Lightweight (0.3–0.8 kg/m²), reducing freight costs by 20%.

Cons:

- 8–10% higher clogging risk in fine-soil environments without robust geotextile.

- Less effective in low-flow vertical applications (10% market share).

- Modular connections may fail in 5% of steep-slope projects.

Sheet Drains

Pros:

- 95% clogging resistance in silty soils, outperforming cells by 10%.

- 25% better waterproofing membrane protection, critical for 75% of foundations.

- Double-dimpled designs handle dual-sided flow, used in 30% of plaza decks.

- Easy installation with adhesives, saving 25% in labor costs.

- Versatile for vertical and horizontal low-flow applications (70% market share).

Cons:

- 20–30% lower flow capacity (5–30 L/min/m²), limiting high-flow use.

- 50% lower compressive strength (200–500 kPa), unsuitable for deep installations.

- Shorter lifespan (30–60 years), requiring 20% more maintenance.

6. Case Study: Drainage System for a Green Roof (5,000 m²)

Project Details: A 5,000 m² green roof for a commercial building requires drainage to manage runoff and support plant growth.

Drainage Cell Solution:

- Product:30 mm HDPE drainage cell (1000 kPa, 20 L/min/m²).

- Material Cost:$4.00/m² x 5,000 = $20,000.

- Installation Cost:$2.00/m² x 5,000 = $10,000.

- Total:$30,000.

- Performance:Handles 20 L/min/m², retains 20% moisture for plants, with a 60-year lifespan.

- Savings:30% cheaper than gravel drains ($42,000).

Sheet Drain Solution:

- Product:15 mm HDPE sheet drain (300 kPa, 10 L/min/m²).

- Material Cost:$5.00/m² x 5,000 = $25,000.

- Installation Cost:$2.50/m² x 5,000 = $12,500.

- Total:$37,500.

- Performance:Manages 10 L/min/m², protects membrane by 20%, with a 40-year lifespan.

- Savings:25% cheaper than gravel drains ($50,000).

Outcome: Drainage cells were chosen for their 15% lower cost, 50% higher flow rate, and 20% longer lifespan, saving $7,500 and optimizing plant health.

7. How to Choose Between Drainage Cell vs Sheet Drain

Selecting the right drainage system hinges on project-specific factors. Use these guidelines to make an informed decision:

- Water Flow Volume:Opt for drainage cells for high-flow applications (>15 L/min/m²), like green roofs or sports fields (60% share). Choose sheet drains for low-flow vertical drainage (<10 L/min/m²), like foundations (70% share).

- Load Conditions:Use drainage cells for high compressive loads (>500 kPa), such as green roofs (70% share). Sheet drains suit moderate loads (<500 kPa), like retaining walls (50% share).

- Soil Type:Sheet drains perform 10% better in silty or clay soils due to thicker geotextile, while drainage cells are versatile in sandy or gravelly soils.

- Installation Constraints:Drainage cells install 35% faster in horizontal applications, saving 3–4 days, while sheet drains are 25% easier for vertical walls with adhesives.

- Budget:Drainage cells offer 10–15% lower costs and 30% better ROI for large-scale projects, while sheet drains provide 20% higher value for membrane protection in urban settings.

- Consult Experts:Engage geotechnical engineers, used in 85% of complex projects, to assess flow rates, soil conditions, and ASTM compliance.

8. Conclusion

Drainage cells and sheet drains are vital geosynthetic solutions for efficient water management, but their distinct designs and performance characteristics suit different applications. Drainage cells, with 25–30% higher flow rates (15–40 L/min/m²) and 60–100% greater compressive strength (800–2000 kPa), excel in high-flow, lightweight scenarios like green roofs and planter boxes, offering 10–15% lower costs ($3.00–$6.00/m²). Sheet drains, with superior filtration and 25% better membrane protection, dominate low-flow vertical applications like foundations and retaining walls, despite 10–20% higher costs ($3.50–$7.50/m²). By assessing flow rates, load conditions, soil type, and budget, you can select the right system, saving 20–30% in costs and ensuring 30–100 years of durability. With trends like recycled materials and smart drainage shaping the future, staying informed ensures robust, sustainable water management for your project.

Any questions or inquiries, please contact BPM Geosynthetics.