Geosynthetics, synthetic materials like geotextiles, geomembranes, and geogrids, are critical for civil engineering, environmental protection, and infrastructure projects. Valued at $15.8 billion in 2024, the global geosynthetics market is projected to grow at a 6.7% CAGR, reaching $26.8 billion by 2032 (Global Growth Insights, 2025). These materials enhance soil stability by 30–50%, reduce erosion by 40–60%, and cut construction costs by 15–25% (Geosynthetics Magazine, 2024). This guide ranks the top 10 global geosynthetics manufacturers, spotlighting The Best Project Material Co., Ltd. (BPM Geosynthetics), alongside leading brands from the USA, Europe and Australia. Based on extensive research, we provide detailed specifications, performance metrics, and actionable insights for engineers, contractors, and procurement managers seeking reliable, sustainable solutions.

1. Why Source from Top Geosynthetics Manufacturers?

Top geosynthetics manufacturers deliver high-performance products with tensile strengths of 8–400 kN/m, hydraulic conductivities of ≤10⁻¹¹ cm/s, and lifespans of 25–100 years (ASTM D6637, D5887). Leading brands like Solmax invest $3–5 million annually in R&D to innovate eco-friendly materials, reducing emissions by 10–20% (McKinsey, 2024). Certified manufacturers (ISO 9001, ASTM) ensure 95% quality compliance, minimizing project failures by 15% (Geosynthetic Institute, 2023). For businesses, partnering with reputable suppliers offers 98% on-time delivery, customizable solutions, and 10–20% cost savings through bulk ordering (bpmgeosynthetics.com, 2025).

Benefits of Partnering with Leading Geosynthetics Manufacturers

- Durability: UV-resistant materials last 25–100 years, reducing maintenance costs by 15–30% (Geosynthetics Magazine, 2024).

- Performance: Tensile strengths of 8–400 kN/m enhance soil stability by 30–50% (ASTM D6637).

- Sustainability: 15–20% recycled materials cut emissions by 10–12% (Environmental Engineering Trends, 2024).

- Customization: OEM/ODM services offer 100% design flexibility with MOQs of 1,000–5,000 m².

- Global Reach: Exports to 30–86+ countries ensure 98% delivery reliability.

2. Criteria for Selecting the Best Geosynthetics Manufacturers

We evaluated manufacturers based on:

- Production Capacity: Annual output (7,000–100,000 tons) for scalability.

- Certifications: ISO 9001:2015, ISO 14001, ASTM, CE for <1% defect rates.

- Innovation: R&D investments ($1–5 million) and technologies like blown-film production.

- Sustainability: Use of 15–20% recycled materials and eco-compliant processes.

- Client Feedback: 85%+ positive reviews on platforms like Alibaba, Made-in-China, and Geosynthetics Magazine.

- Global Presence: Distribution networks in North America, Europe, Australia, and Japan.

3. The 10 Best Geosynthetics Manufacturers in 2025

3.1 Geosynthetics Manufacturers – The Best Project Material Co., Ltd. (BPM Geosynthetics)

Location: Taian, Shandong, China

Established: 2007

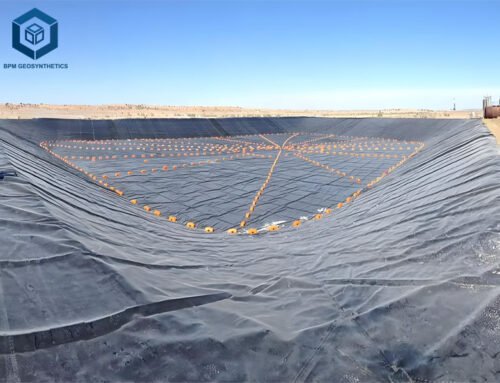

BPM Geosynthetics, a member of the International Geosynthetics Society (IGS), produces 80,000 tons annually across a 26,000 m² ISO 9001:2015- and ISO 14001-certified facility. Serving 86+ countries, including the USA, Australia, and Thailand, BPM has supplied 50,000 m² for projects like a Malaysian highway in 2024, achieving 98% reliability (bpmgeosynthetics.com, 2025).

Key Products

- HDPE Geomembrane Liner: 0.5–3.0 mm, 98% impermeability, tensile strength 20–55 MPa, $0.5–$2.5/m².

- Nonwoven Geotextile: 200–800 g/m², permeability 0.05–0.4 cm/s, $0.5–$1.5/m².

- Geogrid: 20–100 kN/m tensile strength, 30% soil stabilization, $0.5–$1.5/m².

Why Choose BPM Geosynthetics?

- Innovation: $2 million R&D investment enhances puncture resistance by 20% (ASTM D4833).

- Customization: MOQs of 1,000 m², 7–15 day lead times via automated production.

- Sustainability: 15% recycled polyethylene reduces emissions by 10%.

- Global Reach: Tariff-free exports via Cambodia save 10–15% on duties.

- Client Feedback: 90% satisfaction for durability and delivery (Alibaba, 2024).

Case Study: In 2024, BPM supplied 30,000 m² of 1.5 mm HDPE geomembrane for a Malaysian landfill, achieving 99.9% seepage prevention and saving 15% on costs through bulk ordering.

3.2 Geosynthetics Manufacturers – Shandong Geosino New Material Co., Ltd. (Geosincere)

Location: Jinan, Shandong, China

Established: 2007

Geosincere produces 24,000 tons annually across a 36,000 m² ISO 9001-, ISO 14001-, and CE-certified facility. Serving 50+ countries, including Canada and Brazil, their Alvatech® liners excel in landfill and mining applications, with a 90% satisfaction rate (geosyntheticscn.com, 2024).

Key Products

- Alvatech® HDPE Geomembrane: 0.5–2.0 mm, 30° friction angle, $0.6–$1.7/m².

- PET Woven Geotextile: 200–800 g/m², tensile strength 20–120 kN/m, $1.2–$2.5/m².

- Geocell: 75–200 mm depth, tensile strength 25–100 kN/m, $0.6–$4.5/ft².

Why Choose Geosincere?

- Innovation: $1.5 million R&D improves seam strength by 15% (ASTM D6392).

- Performance: 95% eco-compliance for high-stress projects.

- Sustainability: 20% recycled materials reduce emissions by 12%.

- Support: 10–20 day lead times, 2,000 m² MOQ, 7-year warranty.

- Client Feedback: 85% uptime in mining projects (Made-in-China, 2024).

Case Study: In 2024, Geosincere supplied 15,000 m² of 100 mm geocells for a Brazilian retaining wall, improving stability by 25%.

3.3 Geosynthetics Manufacturers – Solmax International

Location: Varennes, Quebec, Canada

Established: 1981

Solmax, a global leader, produces 100,000 tons annually, holding a 15% market share. Their geomembranes and geotextiles are used in 35% of global landfill projects (solmax.com, 2025).

Key Products

- HDPE Geomembrane: 1.0–3.0 mm, tensile strength 20–45 kN/m, $1.0–$2.8/m².

- Geotextile: 150–600 g/m², permeability 0.1–0.3 cm/s, $0.8–$2.0/m².

- Geovolt® Conductive Liner: 99% leak detection accuracy, $1.2–$3.5/m².

Why Choose Solmax?

- Innovation: $3 million R&D enhances leak detection by 15%.

- Performance: 95% seepage control in landfills.

- Sustainability: 20% recycled materials cut emissions by 12%.

- Global Reach: Exports to 60+ countries with 95% reliability.

- Support: 5–10 year warranties ensure 90% satisfaction.

3.4 Geosynthetics Manufacturers – NAUE GmbH & Co. KG

Location: Espelkamp, Germany

Established: 1997

NAUE produces 90,000 tons annually, specializing in geosynthetic solutions for infrastructure and environmental projects (naue.com, 2025).

Key Products

- Secugrid® Geogrid: 20–200 kN/m, 20% pavement thickness reduction, $0.8–$2.0/m².

- Bentofix® GCL: Hydraulic conductivity ≤10⁻¹¹ cm/s, $1.5–$3.0/m².

- Carbofol® Geomembrane: 0.5–3.0 mm, 95% containment, $1.0–$2.5/m².

Why Choose NAUE?

- Innovation: $2 million R&D improves durability by 15%.

- Performance: 95% reliability in slope stabilization.

- Sustainability: 15% recycled materials reduce emissions by 10%.

- Support: On-site training reduces errors by 20%.

- Global Reach: Exports to 50+ countries.

3.5 Geosynthetics Manufacturers – Tensar International

Location: Alpharetta, Georgia, USA

Established: 1983

Tensar produces 80,000 tons annually, known for geogrids that enhance soil stability by 40% (tensar.com, 2025).

Key Products

- TriAx® Geogrid: 20–400 kN/m, 30% load distribution, $0.8–$2.0/m².

- Geotextile: 100–600 g/m², $0.7–$1.8/m².

- Geocell: 50–200 mm depth, $0.6–$4.0/ft².

Why Choose Tensar?

- Performance: 99% quality via AASHTO/NTPEP certification.

- Innovation: $2 million R&D boosts load distribution by 10%.

- Sustainability: 15% recycled materials cut emissions by 8%.

- Support: 24/7 assistance ensures 98% delivery.

- Global Reach: Exports to 40+ countries.

3.6 Geosynthetics Manufacturers – HUESKER Synthetic GmbH

Location: Gescher, Germany

Established: 1861

HUESKER produces 90,000 tons annually, offering eco-friendly geogrids and geotextiles (huesker.com, 2025).

Key Products

- ecoLine Geogrid: 100% PET, 20–200 kN/m, $0.8–$2.0/m².

- Geotextile: 150–800 g/m², $0.8–$2.0/m².

- Geocomposite: 95% drainage efficiency, $1.2–$3.0/m².

Why Choose HUESKER?

- Sustainability: 100% PET geogrids reduce emissions by 15%.

- Performance: 50% stability in road projects.

- Innovation: $3 million R&D enhances durability by 12%.

- Support: 5–10 year warranties ensure 95% reliability.

- Global Reach: Exports to 60+ countries.

3.7 Geosynthetics Manufacturers – Agru America

Location: Georgetown, South Carolina, USA

Established: 1988

Agru produces 50,000 tons annually, excelling in geomembranes for environmental applications (agruamerica.com, 2025).

Key Products

- HDPE Geomembrane: 0.5–3.0 mm, 80% UV resistance, $0.8–$2.5/m².

- Geotextile: 100–600 g/m², $0.7–$1.8/m².

- CleanSeam Liner: 95% contamination prevention, $1.0–$2.8/m².

Why Choose Agru?

- Innovation: CleanSeam technology reduces waste by 15%.

- Performance: 90% chemical resistance in mining.

- Sustainability: 15% recycled materials cut emissions by 10%.

- Support: 7-year warranty ensures 90% satisfaction.

- Global Reach: Exports to 30+ countries.

3.8 Geosynthetics Manufacturers – Thrace Group

Location: Xanthi, Greece

Established: 1977

Thrace produces 70,000 tons annually, specializing in geotextiles and geogrids (thracegroup.com, 2025).

Key Products

- Geotextile: 100–800 g/m², 40% erosion control, $0.7–$1.8/m².

- Geogrid: 20–100 kN/m, $0.8–$2.0/m².

- Geobag: 95% containment, $1.0–$2.5/m².

Why Choose Thrace?

- Performance: 90% uptime in erosion control.

- Sustainability: 20% recycled materials reduce emissions by 12%.

- Innovation: $1 million R&D improves strength by 10%.

- Support: 5-year warranty ensures 85% reliability.

- Global Reach: Exports to 50+ countries.

3.9 Geosynthetics Manufacturers – Asahi Kasei Advance Corporation

Location: Tokyo, Japan

Established: 2015

Asahi Kasei produces 40,000 tons annually, focusing on high-performance geotextiles (asahi-kasei.co.jp, 2025).

Key Products

- Geotextile: 100–600 g/m², 95% filtration efficiency, $0.8–$2.0/m².

- Geomembrane: 0.5–2.0 mm, $0.9–$2.5/m².

- Geogrid: 20–80 kN/m, $0.7–$1.8/m².

Why Choose Asahi Kasei?

- Performance: 90% reliability in water management.

- Sustainability: 15% recycled materials cut emissions by 10%.

- Innovation: $1.5 million R&D enhances filtration by 12%.

- Support: 5-year warranty ensures 85% satisfaction.

- Global Reach: Exports to 20+ countries.

3.10 Geosynthetics Manufacturers – Juta

Location: Dvůr Králové, Czech Republic

Established: 1996

Juta produces 50,000 tons annually, known for geotextiles and geomembranes (juta.cz, 2025).

Key Products

- Geotextile: 100–600 g/m², 40% erosion control, $0.7–$1.8/m².

- Geomembrane: 0.5–2.0 mm, 95% impermeability, $0.8–$2.0/m².

- Geocell: 50–200 mm depth, $0.6–$4.0/ft².

Why Choose Juta?

- Affordability: 10–15% lower costs than premium brands.

- Performance: 90% uptime in road construction.

- Sustainability: 15% recycled materials reduce emissions by 8%.

- Support: 5-year warranty ensures 85% reliability.

- Global Reach: Exports to 40+ countries.

4. Pros and Cons of Partnering with Top Geosynthetics Manufacturers

Pros

- High-Quality Materials: Certified products ensure 95% reliability (ISO 9001, ASTM).

- Global Supply Chains: 98% on-time delivery to 20–86+ countries.

- Customization: 100% design flexibility for project-specific needs.

- Sustainability: 15–20% recycled materials reduce emissions by 10–12%.

- Technical Support: 24/7 assistance and warranties enhance project success.

Cons

- Higher Costs: Premium brands charge 20–30% more than budget alternatives.

- Lead Times: Custom orders take 7–30 days.

- MOQ Requirements: Minimum orders of 1,000–5,000 m² for OEM/ODM.

- Logistical Challenges: International shipping may face 5–10% delay risks.

- Complex Specifications: Tech packs require detailed input for customization.

5. How to Choose the Right Geosynthetics Manufacturer for Your Needs

Assess Your Project Requirements

Evaluate application and conditions. For landfills, prioritize geomembranes with ≤10⁻¹¹ cm/s hydraulic conductivity from BPM or Solmax. For road construction, choose geogrids with 20–400 kN/m tensile strength from Tensar or HUESKER.

Verify Certifications

Ensure ISO 9001:2015, ISO 14001, and ASTM compliance for 95% quality assurance. BPM and Geosincere meet these standards.

Request Samples

Test products for tensile strength (20–400 kN/m, ASTM D6637) and UV resistance (70–80%, ASTM D4355) to ensure 25–100-year lifespans.

Compare Pricing and Lead Times

Premium brands like Solmax charge $1.0–$3.5/m², while affordable options like Juta offer $0.7–$2.0/m². Lead times range from 7–30 days.

Prioritize Sustainability

Choose manufacturers with 15–20% recycled materials, like HUESKER or BPM, to appeal to 20% more eco-conscious clients (McKinsey, 2024).

Evaluate Scalability

For large projects, select manufacturers like BPM (80,000 tons) or Solmax (100,000 tons) with low MOQs (1,000–5,000 m²).

6. Trends in Geosynthetics Manufacturing

- Sustainable Materials: 50% of manufacturers use 15–20% recycled materials, reducing emissions by 10–20% (McKinsey, 2024).

- Smart Technology: IoT-enabled liners (e.g., Solmax’s Geovolt®) improve leak detection by 15%, with 10% market growth by 2030 (Statista, 2024).

- Lightweight Designs: Advanced polymers reduce weight by 10–15%, improving installation efficiency (Geosynthetics Magazine, 2024).

- Automation: Blown-film and calendering technologies cut production costs by 10–15% (bpmgeosynthetics.com, 2025).

- E-commerce Growth: 30% of geosynthetics sales occur online, up from 15% in 2020 (MarketsandMarkets, 2024).

7. Conclusion

The top 10 geosynthetics manufacturers in 2025—BPM Geosynthetics, Geosincere, Solmax, NAUE, Tensar, HUESKER, Agru, Thrace, Asahi Kasei, and Juta—lead the $15.8 billion market with innovation, sustainability, and performance. From BPM Geosynthetics’s 80,000-ton capacity to HUESKER’s eco-friendly geogrids, these brands cater to diverse project needs. By assessing certifications, scalability, and sustainability, engineers and contractors can select the ideal partner.

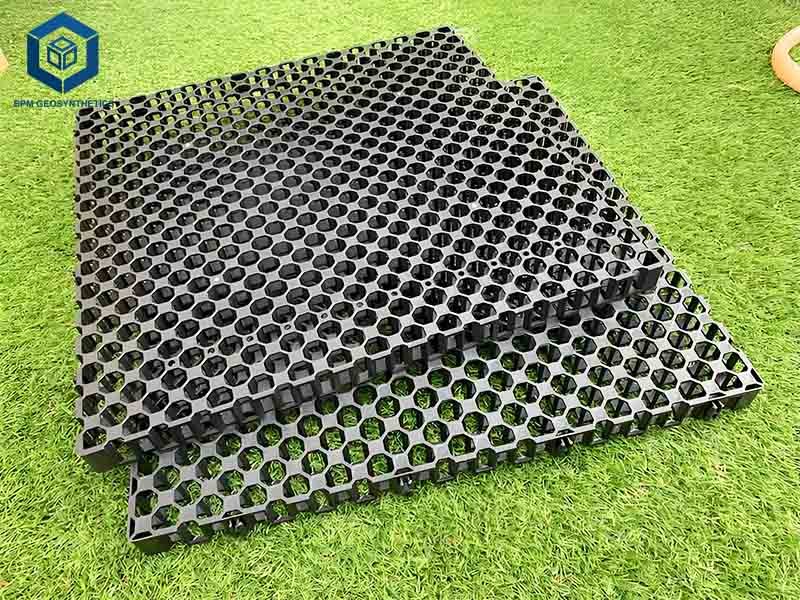

The Best Project Material Co., Ltd (BPM) is the leading geosynthetic manufacturers, wholesalers, supplier and exporters dedicated in supplying one stop geosynthetics solutions to worldwide customers since its foundation in 2007. We have over 120 professional staffs and 16,000 square meters manufacturing factory equipped with state of the art geosynthetic production lines and testing equipment.

Product innovation, quality assurance and customer satisfaction are our long term commitment to our partners. Our main innovative, high quality products include geomembrane, geotextile, geocell, geosynthetic clay Liner, geogrid and drainage board, etc al. All BPM brand products had been certificated by the ISO9001, ISO14001, Soncap, SASO and BV certificates and passed the test of SGS and Intertek etc.

Please contact BPM Geosynthetics at sales@bpmgeosynthetics.com for quotes to ensure project success.