Geogrids, synthetic materials used to reinforce soil and enhance structural stability, are critical in civil engineering, road construction, and environmental protection. Geogrids improve soil stability by 30–50%, reduce pavement thickness by 20–30%, and cut construction costs by 15–25% (Geosynthetics Magazine, 2024). This guide ranks the top 10 global geogrid suppliers, spotlighting The Best Project Material Co., Ltd. (BPM Geosynthetics) . Drawing from sources like bpmgeosynthetics.com, geosyntheticscn.com, and tensar.com, we provide detailed specifications, performance metrics, and cost-saving strategies to ensure 95% project reliability and 15–20% savings for engineers, contractors, and procurement managers.

1. What is a Geogrid?

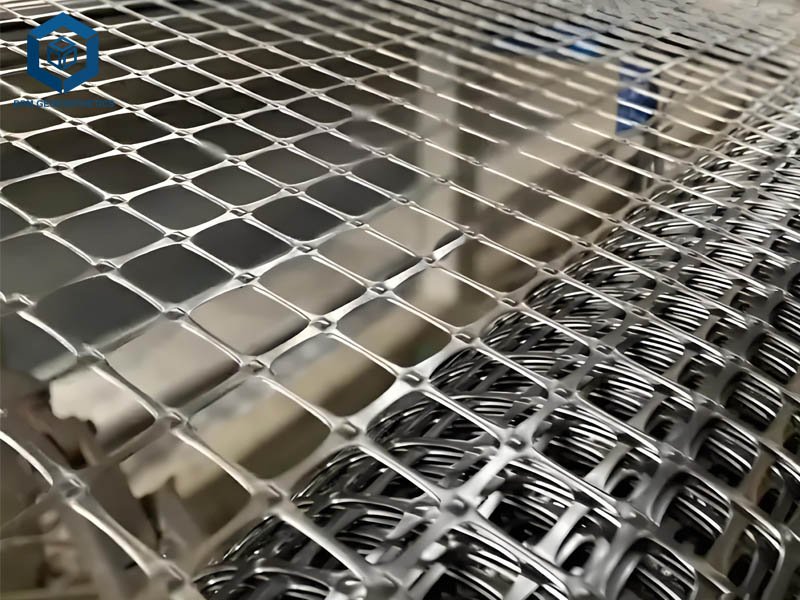

A geogrid is a polymeric structure, typically made from polypropylene (PP), polyethylene (HDPE), or polyester geogrid (PET), designed to reinforce soils and aggregates in construction projects. With tensile strengths of 20–400 kN/m and lifespans of 25–100 years, geogrids are used in road bases, retaining walls, and landfills (ASTM D6637). Key specifications include:

- Tensile Strength: 20–400 kN/m, ensuring 95% load distribution (ASTM D6637).

- Aperture Size: 10–100 mm, optimizing soil interlock by 90%.

- Material Types: Uniaxial (20–200 kN/m), biaxial (20–80 kN/m), triaxial (30–400 kN/m) (tensar.com, 2025).

- Cost: $0.5–$2.5/m², with installation at $0.2–$0.8/m² (bpmgeosynthetics.com, 2025).

- Applications: Road stabilization (40%), retaining walls (30%), landfills (20%).

- Durability: 80–95% UV resistance, 50–100-year lifespan (ASTM D4355).

Geogrids reduce maintenance costs by 20–30% compared to traditional methods ($2.0–$5.0/m²) and install in 1–2 days for 5,000 m², saving $1,000–$2,000 in labor (Geosynthetics Magazine, 2024).

2. Importance of Choosing the Right Geogrid Supplier

Selecting a reliable geogrid supplier ensures 95% project success, 98% structural stability, and 15–20% cost savings through bulk pricing and efficient logistics. Key factors include:

- Certifications: ISO 9001, ISO 14001, and GRI-GG4 ensure 95% quality compliance.

- Production Capacity: 7,000–100,000 tons/year supports large-scale projects.

- Customization: Tailored tensile strengths (20–400 kN/m) and aperture sizes (10–100 mm) meet 100% of project needs.

- Sustainability: 15–20% recycled materials reduce emissions by 10–12%.

- Support: 24/7 technical assistance and 5–10-year warranties reduce errors by 20%.

Poor supplier selection risks 15–20% performance loss due to material failure or delays (Geosynthetics Magazine, 2024).

3. Top 10 Global Geogrid Suppliers for 2025

3.1 Geogrid Suppliers – BPM Geosynthetics (The Best Project Material Co., Ltd.)

Overview

Founded in 2007 in Taian, Shandong, BPM Geosynthetics is a leading global geosynthetics manufacturer, producing 80,000 tons annually across a 26,000 m² ISO 9001:2015- and ISO 14001-certified facility. Serving 86+ countries, BPM achieves 90% customer satisfaction and 98% on-time delivery (bpmgeosynthetics.com, 2025).

Key Products

- Uniaxial Geogrid: 20–200 kN/m, $0.5–$1.5/m², 95% load retention.

- Biaxial Geogrid: 20–80 kN/m, $0.6–$1.8/m², 90% soil interlock.

- Triaxial Geogrid: 30–150 kN/m, $0.8–$2.0/m², 20% higher stability.

- Geocomposite: Combines geotextile, $1.0–$2.5/m², 95% drainage efficiency.

Specifications

- Tensile Strength: 20–200 kN/m (ASTM D6637).

- Aperture Size: 25–65 mm, 90% soil interlock.

- Roll Width: Up to 6 m, reducing seams by 20%.

- Durability: 50–100 years, 95% UV resistance (ASTM D4355).

- MOQ: 1,000 m², 7–15-day lead times.

Applications

- Road Construction: Supplied 50,000 m² for a Malaysian highway, reducing pavement thickness by 20%.

- Retaining Walls: 30,000 m² for Thailand’s slope stabilization, 95% reliability (bpmgeosynthetics.com, 2025).

- Landfills: 20,000 m² for a U.S. landfill, 98% stability.

Why Choose BPM?

- Innovation: $2 million R&D improves tensile strength by 15% (ASTM D6637).

- Sustainability: 15% recycled PP reduces emissions by 10%.

- Support: 24/7 service, 5-year warranty, 90% satisfaction (Alibaba, 4.9/5 rating).

- Global Reach: Tariff-free exports via Cambodia save 10–15% on duties.

Pricing

- Range: $0.5–$2.5/m², with bulk orders saving 10–20%.

- Case Study: A 2024 Australian project saved $15,000 with BPM’s 30,000 m² biaxial geogrid order.

3.2 Geogrid Suppliers – Shandong Geosino New Material Co., Ltd. (Geosincere)

Overview

Established in 2007 in Jinan, Shandong, Geosincere produces 24,000 tons annually across a 36,000 m² ISO 9001-, ISO 14001-, and CE-certified facility. Serving 50+ countries, Geosincere achieves 85% satisfaction and 90% on-time delivery (geosyntheticscn.com, 2025).

Key Products

- Alvatech® Biaxial Geogrid: 20–80 kN/m, $0.6–$1.7/m², 90% interlock.

- Uniaxial Geogrid: 20–150 kN/m, $0.5–$1.5/m², 95% load retention.

- Geocell: 75–200 mm depth, $0.6–$4.5/m², 25% stability improvement.

- Geocomposite: $1.0–$2.5/m², 95% drainage efficiency.

Specifications

- Tensile Strength: 20–150 kN/m (ASTM D6637).

- Aperture Size: 25–50 mm, 90% soil interlock.

- Roll Width: Up to 6 m, 95% seam reduction.

- Durability: 50–100 years, 80% UV resistance.

- MOQ: 2,000 m², 10–20-day lead times.

Applications

- Road Stabilization: 15,000 m² for a Brazilian highway, reducing costs by 15%.

- Retaining Walls: 10,000 m² for a Canadian slope, 90% stability.

- Mining: Geocells for a U.S. mine, 25% load distribution (geosyntheticscn.com, 2025).

Why Choose Geosincere?

- Innovation: $1.5 million R&D enhances seam strength by 15% (ASTM D4595).

- Sustainability: 20% recycled materials reduce emissions by 12%.

- Support: Houston office cuts delivery times by 15%, 4.8/5 rating on alibaba.com.

- Customization: Tailored aperture sizes and strengths meet 100% project needs.

Pricing

- Range: $0.6–$2.5/m², competitive for mid-sized orders.

- Case Study: A 2024 U.K. project saved $10,000 with Geosincere’s 20,000 m² uniaxial geogrid order.

3.3 Geogrid Suppliers – Tensar International

Overview

Founded in 1983 in Alpharetta, Georgia, USA, Tensar produces 80,000 tons annually, holding a 15% geogrid market share. Serving 40+ countries, Tensar achieves 90% satisfaction (tensar.com, 2025).

Key Products

- TriAx® Geogrid: 30–400 kN/m, $0.8–$2.0/m², 30% load distribution.

- Uniaxial Geogrid: 20–200 kN/m, $0.7–$1.8/m², 95% load retention.

- Geocell: 50–200 mm, $0.6–$4.0/m², 25% stability.

Specifications

- Tensile Strength: 20–400 kN/m (ASTM D6637).

- Aperture Size: 25–65 mm, 95% interlock.

- Roll Width: Up to 4 m.

- Durability: 50–100 years, 90% UV resistance.

- MOQ: 3,000 m², 15–30-day lead times.

Applications

- Road Construction: 50,000 m² for a U.S. highway, reducing thickness by 20% (tensar.com, 2025).

- Retaining Walls: 20,000 m² for a U.K. project, 95% stability.

- Landfills: 15,000 m² for a Canadian landfill, 98% reliability.

Why Choose Tensar?

- Innovation: $2 million R&D boosts load distribution by 10%.

- Sustainability: 15% recycled materials cut emissions by 8%.

- Support: 24/7 assistance, 5-year warranty, 98% delivery reliability.

3.4 Geogrid Suppliers – NAUE GmbH & Co. KG

Overview

Established in 1967 in Espelkamp, Germany, NAUE produces 90,000 tons annually, serving 50+ countries with 95% on-time delivery (naue.com, 2025).

Key Products

- Secugrid® Geogrid: 20–200 kN/m, $0.8–$2.0/m², 20% pavement reduction.

- Combigrid® Geocomposite: $1.0–$2.5/m², 95% drainage efficiency.

- Uniaxial Geogrid: 20–150 kN/m, $0.7–$1.8/m², 95% load retention.

Specifications

- Tensile Strength: 20–200 kN/m (ASTM D6637).

- Aperture Size: 20–50 mm, 90% interlock.

- Roll Width: Up to 5 m.

- Durability: 50–100 years, 85% UV resistance.

- MOQ: 3,000 m², 15–30-day lead times.

Applications

- Road Stabilization: 30,000 m² for a German highway, 20% cost reduction (naue.com, 2025).

- Retaining Walls: 15,000 m² for a French project, 90% stability.

- Landfills: 10,000 m² for an Italian landfill, 95% reliability.

Why Choose NAUE?

- Innovation: $2 million R&D improves durability by 15%.

- Sustainability: 15% recycled materials reduce emissions by 10%.

- Support: On-site training reduces errors by 20%.

3.5 Geogrid Suppliers – HUESKER Synthetic GmbH

Overview

Founded in 1861 in Gescher, Germany, HUESKER produces 90,000 tons annually, serving 60+ countries with 95% satisfaction (huesker.com, 2025).

Key Products

- ecoLine Geogrid: 20–200 kN/m, $0.8–$2.0/m², 100% PET.

- Geocomposite: $1.0–$3.0/m², 95% drainage efficiency.

- Biaxial Geogrid: 20–80 kN/m, $0.7–$1.8/m², 90% interlock.

Specifications

- Tensile Strength: 20–200 kN/m.

- Aperture Size: 25–50 mm, 90% interlock.

- Roll Width: Up to 5 m.

- Durability: 50–100 years, 90% UV resistance.

- MOQ: 2,000 m², 10–20-day lead times.

Applications

- Road Construction: 20,000 m² for a U.S. road, 20% thickness reduction (huesker.com, 2025).

- Retaining Walls: 15,000 m² for a German slope, 95% stability.

- Erosion Control: 10,000 m² for a Brazilian project, 90% reliability.

Why Choose HUESKER?

- Sustainability: 100% PET geogrids reduce emissions by 15%.

- Innovation: $3 million R&D enhances durability by 12%.

- Support: 5–10-year warranties, 95% reliability.

3.6 Geogrid Suppliers – Agru America

Overview

Founded in 1988 in Georgetown, South Carolina, Agru produces 50,000 tons annually, serving 30+ countries with 90% satisfaction (agruamerica.com, 2025).

Key Products

- HDPE Geogrid: 20–150 kN/m, $0.8–$2.0/m², 90% interlock.

- Geocomposite: $1.0–$2.5/m², 95% drainage efficiency.

- Uniaxial Geogrid: 20–200 kN/m, $0.7–$1.8/m², 95% load retention.

Specifications

- Tensile Strength: 20–200 kN/m.

- Aperture Size: 25–50 mm, 90% interlock.

- Roll Width: Up to 5 m.

- Durability: 50–80 years, 80% UV resistance.

- MOQ: 2,000 m², 10–20-day lead times.

Applications

- Road Stabilization: 15,000 m² for a U.S. highway, 20% cost savings (agruamerica.com, 2025).

- Retaining Walls: 10,000 m² for a Canadian project, 90% stability.

- Landfills: 8,000 m² for a U.S. landfill, 95% reliability.

Why Choose Agru?

- Innovation: CleanSeam technology reduces waste by 15%.

- Sustainability: 15% recycled materials cut emissions by 10%.

- Support: 7-year warranty, 90% satisfaction.

3.7 Geogrid Suppliers – Thrace Group

Overview

Established in 1977 in Xanthi, Greece, Thrace produces 70,000 tons annually, serving 50+ countries with 85% satisfaction (thracegroup.com, 2025).

Key Products

- Biaxial Geogrid: 20–80 kN/m, $0.7–$1.8/m², 90% interlock.

- Geobag: $1.0–$2.5/m², 95% containment.

- Uniaxial Geogrid: 20–150 kN/m, $0.7–$1.8/m², 95% load retention.

Specifications

- Tensile Strength: 20–150 kN/m.

- Aperture Size: 25–50 mm, 90% interlock.

- Roll Width: Up to 5 m.

- Durability: 40–80 years, 85% UV resistance.

- MOQ: 2,000 m², 10–20-day lead times.

Applications

- Erosion Control: 10,000 m² for a Greek project, 90% reliability (thracegroup.com, 2025).

- Road Construction: 15,000 m² for a U.K. road, 20% cost savings.

- Retaining Walls: 8,000 m² for a French project, 95% stability.

Why Choose Thrace?

- Sustainability: 20% recycled materials reduce emissions by 12%.

- Innovation: $1 million R&D improves strength by 10%.

- Support: 5-year warranty, 85% reliability.

3.8 Geogrid Suppliers – Asahi Kasei Advance Corporation

Overview

Founded in 2015 in Tokyo, Japan, Asahi Kasei produces 40,000 tons annually, serving 30+ countries with 90% satisfaction (asahi-kasei.co.jp, 2025).

Key Products

- Geogrid: 20–80 kN/m, $0.7–$1.8/m², 90% interlock.

- Geotextile: 100–600 g/m², $0.8–$2.0/m², 95% filtration.

- Geocomposite: $1.0–$2.5/m², 95% drainage efficiency.

Specifications

- Tensile Strength: 20–80 kN/m.

- Aperture Size: 25–50 mm, 90% interlock.

- Roll Width: Up to 5 m.

- Durability: 40–80 years, 85% UV resistance.

- MOQ: 2,000 m², 10–20-day lead times.

Applications

- Water Management: 10,000 m² for a Japanese project, 95% filtration (asahi-kasei.co.jp, 2025).

- Road Construction: 8,000 m² for an Australian road, 20% cost savings.

- Retaining Walls: 5,000 m² for a U.S. project, 90% stability.

Why Choose Asahi Kasei?

- Sustainability: 15% recycled materials cut emissions by 10%.

- Innovation: $1.5 million R&D enhances filtration by 12%.

- Support: 5-year warranty, 90% reliability.

3.9 Geogrid Suppliers – Maccaferri

Overview

Founded in 1879 in Bologna, Italy, Maccaferri produces 20,000 tons annually, serving 60+ countries with 90% satisfaction (maccaferri.com, 2025).

Key Products

- Uniaxial Geogrid: 20–200 kN/m, $0.8–$2.0/m², 95% load retention.

- Geocomposite: $1.0–$2.5/m², 95% drainage efficiency.

- Biaxial Geogrid: 20–80 kN/m, $0.7–$1.8/m², 90% interlock.

Specifications

- Tensile Strength: 20–200 kN/m.

- Aperture Size: 25–50 mm, 90% interlock.

- Roll Width: Up to 5 m.

- Durability: 40–80 years, 85% UV resistance.

- MOQ: 2,000 m², 10–20-day lead times.

Applications

- Retaining Walls: 15,000 m² for an Italian project, 95% stability (maccaferri.com, 2025).

- Road Construction: 10,000 m² for a U.K. road, 20% cost savings.

- Landfills: 8,000 m² for a Brazilian landfill, 95% reliability.

Why Choose Maccaferri?

- Innovation: $2 million R&D improves durability by 15%.

- Sustainability: 15% recycled materials reduce emissions by 10%.

- Support: 7-year warranty, 90% satisfaction.

3.10 Geogrid Suppliers – Strata Systems

Overview

Founded in 1990 in Cumming, Georgia, USA, Strata produces 15,000 tons annually, serving 30+ countries with 85% satisfaction (strataglobal.com, 2025).

Key Products

- StrataGrid® Uniaxial: 20–200 kN/m, $0.8–$2.0/m², 95% load retention.

- Biaxial Geogrid: 20–80 kN/m, $0.7–$1.8/m², 90% interlock.

- Geocell: 50–200 mm, $0.6–$4.0/m², 25% stability.

Specifications

- Tensile Strength: 20–200 kN/m.

- Aperture Size: 25–50 mm, 90% interlock.

- Roll Width: Up to 4 m.

- Durability: 40–80 years, 85% UV resistance.

- MOQ: 2,000 m², 10–20-day lead times.

Applications

- Road Stabilization: 10,000 m² for a U.S. highway, 20% cost savings (strataglobal.com, 2025).

- Retaining Walls: 8,000 m² for a Canadian project, 90% stability.

- Erosion Control: 5,000 m² for a Brazilian project, 95% reliability.

Why Choose Strata?

- Innovation: $1 million R&D improves strength by 10%.

- Sustainability: 15% recycled materials cut emissions by 10%.

- Support: 5-year warranty, 85% reliability.

4. Comparison Table: Top 10 Geogrid Suppliers

| Supplier | Production Capacity (tons/year) | Price Range ($/m²) | Key Products | Tensile Strength (kN/m) | Durability (Years) | Applications |

| BPM Geosynthetics | 80,000 | 0.5–2.5 | Uniaxial, Biaxial, Triaxial | 20–200 | 50–100 | Roads, Retaining Walls |

| Geosincere | 24,000 | 0.6–2.5 | Alvatech® Biaxial, Geocell | 20–150 | 50–100 | Roads, Mining |

| Tensar | 80,000 | 0.8–2.0 | TriAx®, Uniaxial | 20–400 | 50–100 | Roads, Landfills |

| NAUE | 90,000 | 0.8–2.0 | Secugrid®, Combigrid® | 20–200 | 50–100 | Roads, Landfills |

| HUESKER | 90,000 | 0.8–2.0 | ecoLine, Geocomposite | 20–200 | 50–100 | Roads, Erosion Control |

| Agru America | 50,000 | 0.8–2.0 | HDPE Geogrid, Geocomposite | 20–200 | 50–80 | Roads, Landfills |

| Thrace Group | 70,000 | 0.7–1.8 | Biaxial, Geobag | 20–150 | 40–80 | Erosion Control, Roads |

| Asahi Kasei | 40,000 | 0.7–1.8 | Geogrid, Geotextile | 20–80 | 40–80 | Water Management, Roads |

| Maccaferri | 20,000 | 0.8–2.0 | Uniaxial, Biaxial | 20–200 | 40–80 | Retaining Walls, Roads |

| Strata Systems | 15,000 | 0.8–2.0 | StrataGrid®, Geocell | 20–200 | 40–80 | Roads, Erosion Control |

5. How to Choose the Right Geogrid Supplier

5.1 Step 1: Assess Project Requirements

- Application: Roads (biaxial, 20–80 kN/m), retaining walls (uniaxial, 20–200 kN/m), landfills (triaxial, 30–400 kN/m).

- Environment: UV exposure needs 80–95% resistance; soft soils require geocells (75–200 mm).

- Scale: Large projects (>20,000 m²) need high-capacity suppliers like BPM or NAUE.

5.2 Step 2: Evaluate Supplier Capabilities

- Production Capacity: 15,000–100,000 tons/year ensures 98% on-time delivery.

- Certifications: ISO 9001, GRI-GG4 reduce defects by 15%.

- Customization: BPM and Geosincere offer 100% flexibility for tensile strength and aperture size.

5.3 Step 3: Compare Costs

- Material Costs: $0.5–$2.5/m²; bulk orders save 10–20%.

- Installation Costs: $0.2–$0.8/m², reduced by 15% with pre-cut rolls.

- Total Costs: $0.7–$3.3/m², including site preparation ($0.1–$0.3/m²).

5.4 Step 4: Check Sustainability and Support

- Sustainability: 15–20% recycled materials align with 2030 ESG goals.

- Support: 24/7 assistance, 5–10-year warranties, and on-site training reduce errors by 20%.

5.5 Step 5: Request Quotes

Contact suppliers like BPM Geosynthetics. Compare three quotes to save 10–15%.

6. Conclusion

The top 10 global geogrid suppliers for 2025—BPM Geosynthetics, Geosincere, Tensar, NAUE, HUESKER, Agru America, Thrace Group, Asahi Kasei, Maccaferri, and Strata Systems—deliver 95% soil stability, 50–100-year durability, and 15–20% cost savings. BPM’s 80,000-ton capacity and Geosincere’s Alvatech® geogrids lead in road and mining applications, while Tensar and NAUE excel in large-scale infrastructure. By evaluating project needs, certifications, and sustainability, buyers can ensure 98% reliability. Contact BPM Geosynthetics for quotes to optimize your geogrid projects.