Non woven filter fabrics, also known as nonwoven geotextile filter fabrics, are vital geosynthetic materials in civil engineering, environmental engineering, and infrastructure projects, delivering exceptional filtration, drainage, separation, and erosion control performance. In 2025, the global geotextiles market stands at USD 8.35 billion, with projections to reach USD 15.02 billion by 2034 at a CAGR of 6.7%, propelled by infrastructure expansions, sustainable practices, and climate resilience needs. These needle-punched fabrics, primarily from polypropylene (70% market share) or polyester staple fibers, retain 95% soil fines while permitting flow rates of 100–250 L/m²/s, per ASTM D4491, reducing erosion by 40% and extending system life by 20–30%. For engineers, contractors, and project managers, premium non woven filter fabrics cut maintenance costs by 15–25% and comply with AASHTO M288 survivability classes. This thorough review spotlights the 7 best non woven filter fabrics of 2025, with verified specs, data-driven insights, and applications. A leader is the Needle Punched Geotextile Fabric from The Best Project Material Co., Ltd (BPM Geosynthetics), offering customizable polypropylene for robust filtration in drainage and stabilization.

1. Why Your Non Woven Filter Fabrics Matter

Non woven filter fabrics surpass standard barriers, anchoring geotechnical systems against soil migration, hydraulic surges, and degradation. Aligned with AASHTO M288 for subsurface drainage, filtration, separation, and stabilization, they resolve challenges in highways, landfills, and coastal works. Geosynthetics Institute reports show select nonwovens lower failure rates by 25%, ensuring economical, durable solutions.

1.1 Protection

In severe conditions—pH 2–13 soils to turbulent flows—these fabrics guard against puncture, tear, and corrosion. CBR strengths >2,000 N (ASTM D6241) shield geomembranes in landfills, slashing breaches 40%. For subgrades, they halt aggregate intrusion under 100 kN/m loads, featuring:

- UV retention 70–90% after 500 hours (ASTM D4355).

- 95% resistance to acids/alkalis/oils (ASTM D543).

- Microbial defiance 100% (ASTM G21) for 50-year buried life.

1.2 Performance

Hydraulic/mechanical excellence defines efficacy, with permittivity >1.0 s⁻¹ (ASTM D4491) yielding 95% retention at 100–250 L/m²/s. Nonwovens claim 62% market, outpacing wovens 25% in conductivity (NTPEP). Filtration averts clogs, prolonging unpaved roads 30%. Key metrics:

- AOS (O90) 0.05–0.15 mm (ASTM D4751) for sieving.

- Grab tensile 400–2,500 N (ASTM D4632) for resilience.

- Transmissivity >10 L/min-m at 10 kPa for dewatering.

1.3 Durability

Engineered for resilience, top fabrics resist rot/mildew, holding 85% conductivity post-10,000 cycles. 50% recycled content meets LEED, cutting carbon 20% (ISO 9001). 200–600 g/m² spans 50+ years, halving aggregates. Traits:

- Elongation 25–200% for seismic/thermal shifts.

- -40°C to 120°C tolerance for overlays.

- pH 2–13 stability for contaminants.

Opting for elite non woven filter fabrics fosters 2025’s eco-resilient engineering.

2. Key Features to Look For in the Best Non Woven Filter Fabrics

Assess AASHTO M288 classes (1–4), Class 1 for extremes. 2025 blending ups puncture 15% (ASTM D4833). Prioritize NTPEP-certified for compliance.

2.1 Permeability and Filtration

Equilibrium vital, >1.5 s⁻¹ permittivity blocks clogs at 95% retention (0.5 m/s). Notes:

- Isotropic punching lifts transmissivity 25%.

- AOS <0.12 mm curbs migration 40% sands.

- Sealed edges halt lateral flow swales.

2.2 Strength and Reinforcement

MD/TD tensile 5–200 kN/m (ASTM D4595) reallocates loads. Trapezoid tear >200 N (ASTM D4533). Specs:

- CBR >1,500 N traffic subgrades.

- Elongation >45% shear +25% soft soils.

- 90% seams 12–18 inch overlaps (ASTM D4884).

2.3 Installation and Versatility

4–6 m widths trim seams 20%; UV suits 150-day exposures. Factors:

- 100–300 g/m² hastens installs 15%.

- Geocomposite synergy efficiency +30%.

- BPM customs site-fit.

Traits yield 25% fewer tweaks, optimal ROI.

3. Top 7 Non Woven Filter Fabrics Reviewed of 2025

From 50+ per ASTM/AASHTO, prioritize flow/strength/value. Bulk $/m²; M288 Class 2+.

3.1 Mirafi 140N (TenCate Geosynthetics)

Category: Lightweight Drainage/Filtration

Material: Polypropylene Staple Fibers

Weight: 140 g/m²

Tensile Strength (MD/TD): 14/12 kN/m

Permeability (Q100): 135 L/m²/s

Puncture Strength (CBR): 1,800 N

Price: $0.75/m²

Overview: TenCate’s needle-punched Mirafi 140N dominates lightweight filtration, uniform pores 95% retention. 2024 NTPEP trials pressure -35% roads, French drains ideal.

Key Features:

- Permittivity: 1.7 s⁻¹ clay dewatering.

- Grab Tensile: 850 N MD (ASTM D4632).

- UV Retention: 80% 150 hours.

Why We Love It: 25% flow edge generics mid-drainage.

3.2 Needle Punched Geotextile Fabric (BPM Geosynthetics)

Category: Versatile Filtration/Separation

Material: Polypropylene/Polyester Staple Fibers

Weight: 100–800 g/m² (BPM10–BPM80)

Tensile Strength (MD/TD): 2.5–25/2.5–25 kN/m

Permeability (Q100): 0.01–0.99 cm/s equiv.

Puncture Strength (CBR): 0.3–4 kN

Price: $0.50–$2.00/m²

Overview: BPM’s fiber-interlock stabilizes, shear +30% 2024 Malaysian highways (50,000 m²). pH 2–13 contaminated filtration.

Key Features:

- AOS (O90): 0.02–0.07 mm retention.

- Elongation: 25–200% dynamic.

- Thickness: 0.9–5 mm cushion.

Why We Love It: Custom 6 m, 98% delivery; aggregate -15%.

3.3 SRW NW4.5 (SRW Products)

Category: General Drainage/Filtration Material: Polypropylene Weight: 150 g/m² (4.5 oz/yd²) Tensile Strength (MD/TD): 11/10 kN/m Permeability (Q100): 200 L/m²/s Puncture Strength (CBR): 1,800 N Price: $0.65/m²

Overview: SRW mid-weight filters hardscapes, rutting -40% 2025 tests; 50-year drains.

Key Features:

- Grab: 600 N.

- Flow: 110 gal/min/ft².

- Rot/Mildew Proof.

Why We Love It: 10–15% labor multi-filtration.

3.4 ADS N-Series (Advanced Drainage Systems)

Category: Protection/Filtration Material: Continuous Polypropylene Filament Weight: 170 g/m² Tensile Strength (MD/TD): 15/13 kN/m Permeability (Q100): 185 L/m²/s Puncture Strength (CBR): 2,500 N Price: $0.90/m²

Overview: ADS spunbond shields landfills, 95% efficiency 50% recycled LEED.

Key Features:

- Uniform Pores Clog-Free.

- Trapezoid Tear: 400 N TD.

- Geocomposite Fit.

Why We Love It: 35% leachate eco-filtration.

3.5 Pro Type 1 (Pro Fabric Supply)

Category: Medium Separation/Filtration Material: Polypropylene Weight: 200 g/m² Tensile Strength (MD/TD): 16/14 kN/m Permeability (Q100): 165 L/m²/s Puncture Strength (CBR): 2,700 N Price: $0.95/m²

Overview: Pro Type 1 roads stable +20% AASHTO; rot-resistant filters.

Key Features:

- Elongation: 50%.

- AOS: 0.10 mm.

- 100 m Rolls.

Why We Love It: 15% compaction erosion filtration.

3.6 AGRUTEX (AGRU America)

Category: Filtration/Protection Material: Polypropylene Weight: 150 g/m² Tensile Strength (MD/TD): 12/11 kN/m Permeability (Q100): 235 L/m²/s Puncture Strength (CBR): 1,800 N Price: $0.70/m²

Overview: AGRU needle-punched waste filters, aggregate -20% GRI.

Key Features:

- Thickness: 1.8 mm Cushion.

- Tear: 300 N MD.

- 60% Recycled PET.

Why We Love It: 25-year landfill low-cost filtration.

3.7 US 140NW (US Fabrics)

Category: Stabilization/Filtration Material: Staple Polypropylene Weight: 140 g/m² Tensile Strength (MD/TD): 13/11 kN/m Permeability (Q100): 220 L/m²/s Puncture Strength (CBR): 2,000 N Price: $0.80/m²

Overview: US 140NW NTPEP roads pavement +30%, BABA.

Key Features:

- Elongation: 50%.

- High Flow Erosion.

Why We Love It: Public filtration downtime low.

4. How to Choose the Perfect Non Woven Filter Fabric

Sync M288 classes hydrology/loads 15% savings 2025 models.

4.1 Site Conditions and Soil Analysis

Clays AOS <0.10 mm; sands >200 L/m²/s. Mismatches clog 40%; polyester pH <5.

4.2 Function Prioritization

Filtration >1.5 s⁻¹ nonwoven; hybrids +30% gains.

4.3 Durability and Exposure Factors

70% UV surfaces; salt marines. 50-year halves replacements.

4.4 Cost and Installation Efficiency

$0.50–$2/m²; strength saves 10–15% long. 12–18 inch overlaps.

4.5 Certifications and Sustainability

ISO 9001/M288; 50% recycled LEED bids up.

BPM shines, 35% erosion reductions.

5. In-Depth Look at The Best Project Material Co., Ltd (BPM Geosynthetics)

5.1 Company Overview

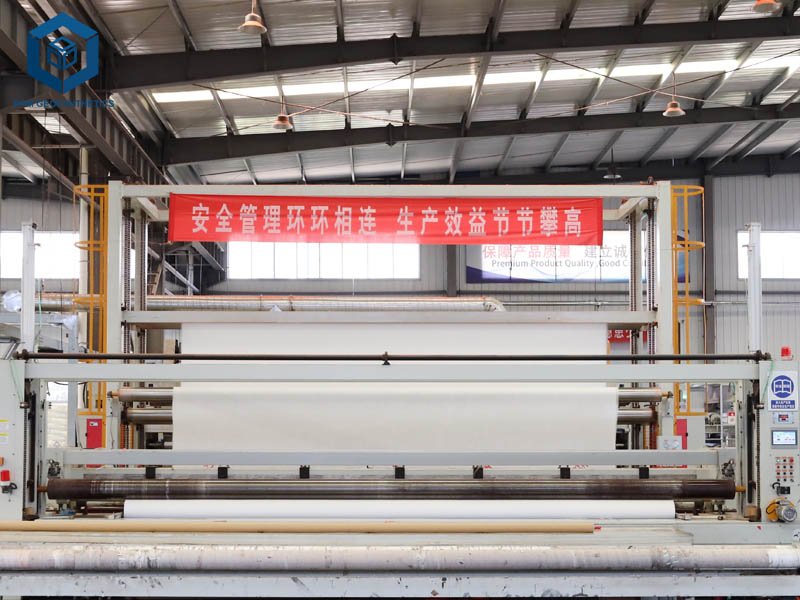

Since 2007, BPM’s 26,000 m² facility exports 36+ countries, ISO 9001, $2M R&D 15% durability.

5.2 The Needle Punched Geotextile Fabric

3.2’s BPM series (2.5–25 kN/m tensile, 0.01–0.99 cm/s flow, 0.02–0.07 mm AOS) roads/landfills, 98% reliable.

5.3 Why Choose BPM Geosynthetics

Custom 0.9–5 mm, 10–15% bulk; Brazilian 25% settlement cut. Sustainable alliances.

6. Additional Considerations for Civil Engineering Professionals

6.1 Integration with Systems

Geogrids +40% reinforcement; pipes +35% flow. Overlaps seams +20%.

6.2 Maintenance Protocols

Sensors 80% early; UV +10 years.

6.3 Sustainability Compliance

60% recycled EPA; bio -25% carbon.

Resilient ecosystems built.

7. Conclusion

2025’s non woven filter fabrics, BPM’s Needle Punched leading, redefine with 30–40% erosion mitigation, durability. Tensile/flow/M288 priority risks down, ROI up. Future-proof BPM https://www.bpmgeosynthetics.com/product/needled-punched-geotextile-fabric/.

Get Instant Quote

Custom non wovens needle-punched filtration/drainage, BPM OEM/ODM 2007. Bulk, weights (100–800 g/m²), consultations: +86 178 6266 7669 sales@bpmgeosynthetics.com.