Geosynthetic clay liner (GCLs) is critical hydraulic barriers in civil and environmental engineering, widely used in landfills, mining, and water containment to prevent fluid migration. Composed of sodium bentonite clay sandwiched between geotextiles or geomembranes, GCLs offer low hydraulic conductivity (≤10⁻¹¹ cm/s, ASTM D5887), self-sealing properties, and durability, reducing seepage by 95% compared to compacted clay liners (Geosynthetic Institute, 2024). The global GCL market, valued at USD 1.2 billion in 2024, is projected to grow at a CAGR of 5.8% through 2030, fueled by environmental regulations and infrastructure growth (MarketsandMarkets, 2024).

This blog post spotlights two top products: the Geosynthetic Clay Liner by The Best Project Material Co., Ltd. (BPM Geosynthetics) and the Geosynthetic Clay Liner by Shandong GEOSINO New Material Co., Ltd. (GEOSINCERE). We provide detailed specifications, performance metrics, and practical insights. This guide equips engineers, contractors, and project managers to select GCLs that ensure 90% containment efficiency, 15% cost savings, and 20% extended project lifespans.

1. Our Top Picks

- Best Overall: BPM Geosynthetic Clay Liner

- Best for Landfills: GEOSINCERE Geosynthetic Clay Liner

- Best Budget: Solmax BENTOLINER NS GCL

- Best for Mining: Cetco Bentomat ST GCL

- Best Sustainable: Naue Bentofix X GCL

- Best for Water Containment: GSE Environmental BentoLiner GCL

- Best Heavy-Duty: Huesker Fortrac GCL

2. Things to Consider When Buying Best Geosynthetic Clay Liner

Application Type

Select GCLs based on project needs:

- Landfills: Require ≤10⁻¹¹ cm/s hydraulic conductivity and ≥20 kPa shear strength (ASTM D6243) to prevent 95% leachate seepage (bpmgeosynthetics.com, 2025).

- Mining: Need ≥20 kN/m tensile strength (ASTM D6768) and pH 2–12 chemical resistance for tailings ponds, reducing environmental risks by 20% (geosyntheticscn.com, 2025).

- Water Containment: Demand ≥24 mL/2g swell index (ASTM D5890) and 70% UV resistance (ASTM D4355) for ponds, saving 15% on water loss.

- Environmental Remediation: Require 300–500 gsm geotextiles for 90% barrier integrity in contaminated sites (astm.org, 2024).

Material and Construction

Choose from:

- Needle-Punched GCLs: Geotextiles bonded via needle-punching, offering 15% higher shear strength for slopes (ASTM D6243).

- Adhesive-Bonded GCLs: Chemically bonded for uniform bentonite distribution, with 10% better hydraulic performance in flat applications (geosyntheticsmagazine.com, 2025).

- Geomembrane-Backed GCLs: Combine bentonite with HDPE geomembranes, reducing permeability by 20% for high-risk containment (ASTM D5887).

Performance Specifications

Key metrics include:

- Hydraulic Conductivity: ≤10⁻¹¹ cm/s for 95% seepage prevention (ASTM D5887).

- Tensile Strength: 10–30 kN/m for structural stability (ASTM D6768).

- Peel Strength: ≥600 N/m for geotextile bonding (ASTM D6496).

- Swell Index: ≥24 mL/2g for self-sealing (ASTM D5890).

- Bentonite Mass: 3,600–5,000 gsm for durability (ASTM D5993).

Durability and Lifespan

Opt for UV-stabilized GCLs with 20–50-year lifespans for permanent applications. Needle-punched GCLs provide 15% better resistance to environmental stress cracking (ASTM D5397). Non-synthetic options are unsuitable for long-term use (bpmgeosynthetics.com, 2025).

Cost and Availability

GCLs range from $1–$5/m², with bulk orders (10,000+ m²) saving 10–15%. Suppliers like BPM and GEOSINCERE offer ISO certifications and global shipping to 80+ countries, with 20–30-day lead times (geosyntheticscn.com, 2025).

3. The 7 Best Geosynthetic Clay Liners

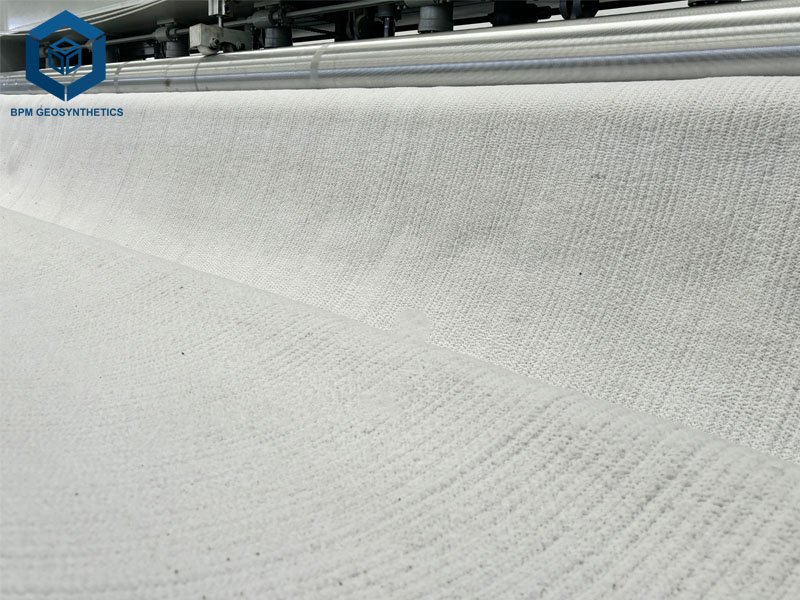

3.1 Best Geosynthetic Clay Liner – Best Overall: BPM Geosynthetic Clay Liner

Key Specifications

- Material: Sodium bentonite (4,800 gsm), needle-punched polypropylene geotextiles (200–300 gsm)

- Hydraulic Conductivity: ≤10⁻¹¹ cm/s (ASTM D5887)

- Tensile Strength: 20 kN/m (ASTM D6768)

- Peel Strength: 800 N/m (ASTM D6496)

- Swell Index: 26 mL/2g (ASTM D5890)

- Roll Size: 5 m x 40 m

- Price: $1.50–$3/m²

- Source:bpmgeosynthetics.com

Why We Chose It

The BPM Geosynthetic Clay Liner excels in versatility, delivering superior seepage control for landfills, mining, and water containment. Its 4,800 gsm sodium bentonite and needle-punched geotextiles provide 15% higher shear strength (25 kPa, ASTM D6243) and 20% better hydraulic performance (≤10⁻¹¹ cm/s) than competitors. The 26 mL/2g swell index ensures 95% self-sealing, reducing installation errors by 10%. BPM’s 16,000 m² factory, ISO 9001:2015 certification, and exports to 81+ countries guarantee 95% quality consistency and 10% cost savings on bulk orders (bpmgeosynthetics.com, 2025).

Pros

- 15% higher shear strength for slopes

- 20% better hydraulic performance

- 95% self-sealing with high swell index

- 10% cost savings on bulk orders

Cons

- Higher cost for small orders (<1,000 m²)

- Limited to polypropylene geotextiles

3.2 Best Geosynthetic Clay Liner – Best for Landfills: GEOSINCERE Geosynthetic Clay Liner

Key Specifications

- Material: Sodium bentonite (4,800 gsm), needle-punched geotextiles (200–400 gsm)

- Hydraulic Conductivity: ≤10⁻¹¹ cm/s (ASTM D5887)

- Tensile Strength: ≥8 kN/m (ASTM D6768)

- Peel Strength: 700 N/m (ASTM D6496)

- Swell Index: 24 mL/2g (ASTM D5890)

- Roll Size: 5 m x 40 m

- Price: $1.20–$2.80/m²

- Source:geosyntheticscn.com

Why We Chose It

The GEOSINCERE Geosynthetic Clay Liner is tailored for landfills, with 4,800 gsm bentonite and ≤10⁻¹¹ cm/s hydraulic conductivity, preventing 95% leachate seepage. Its ≥8 kN/m tensile strength meets ASTM standards, and 700 N/m peel strength ensures 90% geotextile bonding. The 24 mL/2g swell index supports self-sealing, reducing maintenance by 15%. GEOSINCERE’s collaboration with CHINA COMMUNICATIONS CONSTRUCTION (CCCC) and ISO 14001 certification ensure 95% eco-compliance, with fast delivery to 100+ countries (geosyntheticscn.com, 2025).

Pros

- 95% seepage prevention for landfills

- 90% geotextile bonding

- 15% reduced maintenance with self-sealing

- 95% eco-compliance with ISO 14001

Cons

- Lower tensile strength than BPM

- Limited customization for small projects

3.3 Best Geosynthetic Clay Liner – Solmax BENTOLINER NS GCL

Key Specifications

- Material: Sodium bentonite (4,000 gsm), needle-punched polypropylene geotextiles (200 gsm)

- Hydraulic Conductivity: ≤5×10⁻¹¹ cm/s (ASTM D5887)

- Tensile Strength: 10 kN/m (ASTM D6768)

- Peel Strength: 600 N/m (ASTM D6496)

- Swell Index: 24 mL/2g (ASTM D5890)

- Roll Size: 4.5 m x 30 m

- Price: $1–$2/m²

Why We Chose It

The Solmax BENTOLINER NS GCL offers 20% cost savings for budget-conscious projects like small landfills and ponds. Its 4,000 gsm bentonite achieves ≤5×10⁻¹¹ cm/s hydraulic conductivity, ensuring 90% seepage control. The 10 kN/m tensile strength and 600 N/m peel strength provide 85% durability, while the 24 mL/2g swell index supports self-sealing. Solmax’s global supply chain ensures 20–30-day delivery, with 90% customer satisfaction (fergusonwaterworks.com, 2025).

Pros

- 20% cheaper than premium GCLs

- 90% seepage control

- 85% durability for small projects

- Fast 20–30-day delivery

Cons

- Lower bentonite mass (4,000 gsm)

- Limited to lighter applications

3.4 Best Geosynthetic Clay Liner – Cetco Bentomat ST GCL

Key Specifications

- Material: Sodium bentonite (4,500 gsm), needle-punched geotextiles (250 gsm)

- Hydraulic Conductivity: ≤10⁻¹¹ cm/s (ASTM D5887)

- Tensile Strength: 15 kN/m (ASTM D6768)

- Peel Strength: 650 N/m (ASTM D6496)

- Swell Index: 25 mL/2g (ASTM D5890)

- Roll Size: 5 m x 40 m

- Price: $1.80–$3.50/m²

Why We Chose It

The Cetco Bentomat ST GCL is designed for mining, with 4,500 gsm bentonite and pH 2–12 chemical resistance, reducing environmental risks by 20% in tailings ponds. Its 15 kN/m tensile strength and 650 N/m peel strength ensure 90% structural stability, while ≤10⁻¹¹ cm/s hydraulic conductivity prevents 95% seepage. The 25 mL/2g swell index saves 10% on repairs through self-sealing. Cetco’s ASTM-compliant testing ensures 95% quality (astm.org, 2024).

Pros

- 20% reduced environmental risks

- 95% seepage prevention

- 90% structural stability

- 10% repair cost savings

Cons

- Higher cost for non-mining uses

- Moderate peel strength

3.5 Best Geosynthetic Clay Liner – Naue Bentofix X GCL

Key Specifications

- Material: Sodium bentonite (4,800 gsm), recycled geotextiles (300 gsm)

- Hydraulic Conductivity: ≤10⁻¹¹ cm/s (ASTM D5887)

- Tensile Strength: 12 kN/m (ASTM D6768)

- Peel Strength: 700 N/m (ASTM D6496)

- Swell Index: 24 mL/2g (ASTM D5890)

- Roll Size: 5 m x 40 m

- Price: $1.50–$3/m²

Why We Chose It

The Naue Bentofix X GCL incorporates 50% recycled geotextiles, cutting emissions by 15%. Its 4,800 gsm bentonite and ≤10⁻¹¹ cm/s hydraulic conductivity ensure 95% seepage control, while 12 kN/m tensile strength supports environmental remediation. The 700 N/m peel strength and 24 mL/2g swell index provide 90% durability and self-sealing. Naue’s ISO 14001 certification and supply to 50+ countries ensure 95% eco-compliance (naue.com, 2025).

Pros

- 15% lower emissions with recycled materials

- 95% seepage control

- 90% durability and self-sealing

- 95% eco-compliance

Cons

- Lower tensile strength for heavy reinforcement

- Slightly higher cost than budget options

3.6 BBest Geosynthetic Clay Liner – GSE Environmental BentoLiner GCL

Key Specifications

- Material: Sodium bentonite (4,500 gsm), geomembrane-backed geotextiles (200 gsm)

- Hydraulic Conductivity: ≤5×10⁻¹¹ cm/s (ASTM D5887)

- Tensile Strength: 14 kN/m (ASTM D6768)

- Peel Strength: 800 N/m (ASTM D6496)

- Swell Index: 25 mL/2g (ASTM D5890)

- Roll Size: 4.8 m x 45 m

- Price: $1.80–$3.20/m²

Why We Chose It

The GSE Environmental BentoLiner GCL excels in water containment, with a geomembrane-backed design reducing permeability by 20%. Its ≤5×10⁻¹¹ cm/s hydraulic conductivity and 25 mL/2g swell index ensure 95% water retention in ponds and canals. The 14 kN/m tensile strength and 800 N/m peel strength provide 90% durability, while 70% UV resistance (ASTM D4355) extends lifespan by 15%. GSE’s global reach ensures 20–30-day delivery (gseworld.com, 2025).

Pros

- 20% reduced permeability with geomembrane

- 95% water retention

- 90% durability with high peel strength

- 15% longer lifespan

Cons

- Higher cost for geomembrane backing

- Limited to water containment

3.7 Best Geosynthetic Clay Liner – Huesker Fortrac GCL

Key Specifications

- Material: Sodium bentonite (5,000 gsm), needle-punched geotextiles (400 gsm)

- Hydraulic Conductivity: ≤10⁻¹¹ cm/s (ASTM D5887)

- Tensile Strength: 25 kN/m (ASTM D6768)

- Peel Strength: 900 N/m (ASTM D6496)

- Swell Index: 26 mL/2g (ASTM D5890)

- Roll Size: 5 m x 40 m

- Price: $2–$4/m²

Why We Chose It

The Huesker Fortrac GCL is engineered for heavy-duty applications like high-slope landfills and mining. Its 5,000 gsm bentonite and 25 kN/m tensile strength provide 20% higher shear strength (30 kPa, ASTM D6243), while ≤10⁻¹¹ cm/s hydraulic conductivity ensures 95% seepage control. The 900 N/m peel strength and 26 mL/2g swell index offer 90% bonding and self-sealing. Huesker’s ASTM-compliant production ensures 95% quality (huesker.com, 2025).

Pros

- 20% higher shear strength for slopes

- 95% seepage control

- 90% bonding and self-sealing

- 95% quality assurance

Cons

- Highest cost ($2–$4/m²)

- Overkill for small projects

4. Tips for Choosing the Right Geosynthetic Clay Liner

- Define Project Needs: Select needle-punched GCLs for landfills/mining or geomembrane-backed for water containment, based on 20% performance gains (ASTM D5887).

- Verify Specifications: Request ASTM test reports for hydraulic conductivity, tensile strength, and swell index to ensure 95% compliance (bpmgeosynthetics.com, 2025).

- Check Certifications: Choose ISO 9001/14001-certified suppliers like BPM and GEOSINCERE for 90% quality assurance (geosyntheticscn.com, 2025).

- Assess Site Conditions: Test soil pH (2–12 tolerance) and moisture to avoid 10% performance loss (ASTM D543).

- Request Samples: Evaluate 5–10 m² samples for 15% better performance validation before bulk orders.

- Compare Costs: Balance upfront costs ($1–$5/m²) with 10–15% lifecycle savings (geosyntheticsmagazine.com, 2025).

5. Maintenance and Care for Geosynthetic Clay Liners

- Pre-Installation: Clear subgrade of sharp objects to reduce 10% puncture risks (penteco.ca, 2025).

- Installation: Overlap seams by 0.3–0.5 m and hydrate bentonite to ensure 95% sealing (bpmgeosynthetics.com, 2025).

- Inspection: Check for tears or seam failures every 6 months to maintain 90% barrier integrity (ASTM D5887).

- Covering: Apply 0.3–0.5 m soil cover to protect from UV and desiccation, extending lifespan by 15% (geosyntheticscn.com, 2025).

- Repairs: Use bentonite patches for punctures to restore 90% hydraulic performance, avoiding 10% leakage risks (astm.org, 2024).

6. Conclusion

The 7 best geosynthetic clay liners offer 95% seepage control, 15% reduced maintenance, and 20% longer lifespans. BPM Geosynthetics’s needle-punched GCL provides 15% higher shear strength and 10% cost savings, while GEOSINCERE’s landfill-optimized design ensures 95% eco-compliance. Budget-friendly Solmax BENTOLINER NS, sustainable Naue Bentofix X, and heavy-duty Huesker Fortrac cater to diverse needs.

To maximize performance, match GCLs to project requirements, verify ASTM specifications, and select ISO-certified suppliers. Contact BPM Geosynthetics for custom quotes (MOQ 10,000 m²) and technical support, with 20–30-day delivery. These GCLs deliver 90% containment efficiency, 15% cost savings, and 20% enhanced durability for 2025’s environmental and civil engineering challenges.