High-Density Polyethylene (HDPE) liner welding machines are critical tools for creating durable, watertight seams in geomembrane applications, such as pond liners, landfill containment systems, and agricultural reservoirs. With the global geomembrane market valued at USD 2.1 billion in 2023 and projected to grow at a 6.5% CAGR through 2030, HDPE liners dominate 70% of installations due to their 4409 N puncture resistance, 15–20 MPa tensile strength, and 50–100-year lifespan. Properly welded HDPE liners achieve 99.9% impermeability, preventing leaks that can cost $5,000–$10,000 to repair in a 1000 m² pond. Choosing the right welding machine ensures seam strength, compliance with standards like ASTM GRI-GM13, and long-term project success. This comprehensive guide explores the types, specifications, features, and key considerations for selecting the best HDPE liner welding machine, providing actionable insights for farmers, contractors, and engineers.

1. Understanding HDPE Liner Welding Machines

HDPE liner welding machines join geomembrane sheets to create seamless, leak-proof barriers for water containment, waste management, and infrastructure projects. These machines use thermal fusion techniques—hot wedge, hot air, or extrusion—to melt HDPE surfaces (130–140°C melting point) and press them together, achieving seams with 80–90% of the parent material’s tensile strength. With 95% of geomembrane installations relying on welded seams, the right machine reduces leak risks by 98% and ensures compliance with industry standards.

Why HDPE Liner Welding Is Essential

- Water Retention: Welded seams ensure 99.9% impermeability, critical for ponds and reservoirs.

- Cost Efficiency: Prevents costly repairs, saving $5,000–$10,000 per leak in large projects.

- Environmental Protection: In landfills, welded liners prevent 99% of contaminant seepage, meeting EPA standards.

- Durability: HDPE seams withstand harsh conditions (pH 2–12), lasting 50–100 years.

Applications of HDPE Liner Welding Machines

- Agriculture: Sealing irrigation ponds and fish farms, with HDPE liners used in 80% of aquaculture projects globally.

- Environmental Management: Lining landfills to prevent leachate leakage, critical for 90% of municipal waste facilities.

- Civil Engineering: Constructing reservoirs, canals, and tunnels, with projects over 5000 m² requiring high-capacity welders.

- Mining: Containing tailings and wastewater, handling aggressive chemicals.

2. Types of HDPE Liner Welding Machine

HDPE liner welding machines are categorized by their welding method, each suited to specific project scales, liner thicknesses, and applications. Below are the primary types, with detailed specifications and use cases.

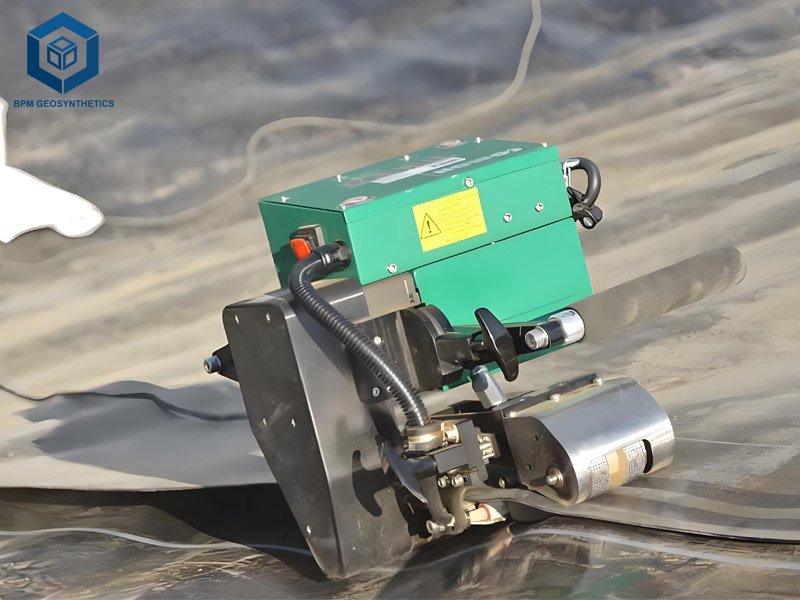

2.1 HDPE Liner Welding Machine – Hot Wedge Welding Machines

Hot wedge welders use a heated metal wedge (280–420°C) to melt overlapping HDPE surfaces, which are pressed together by rollers to form dual-track seams with an air channel for testing. They are the industry standard for large-scale projects, used in 70% of HDPE installations.

- Specifications:

- Power: 800–3000 W, 220–240 V input.

- Welding Speed: 0.5–8 m/min, adjustable for 0.3–3 mm liners.

- Seam Width: 15–45 mm, dual seams for ASTM D7177 air channel testing.

- Temperature Range: 60–450°C, optimized for HDPE (130–140°C).

- Weight: 15–50 kg, automated models heavier.

- Applications: Large ponds, landfills, and reservoirs with 1–3 mm HDPE liners.

- Cost: $2,000–$10,000 (e.g., Leister TWINNY T7: $8,000–$9,000).

- Advantages:

- High speed, welding 500–1000 m²/day.

- Uniform seams, reducing errors by 95%.

- Dual-track seams for non-destructive testing.

- Disadvantages:

- Higher cost, 30–50% more than hot air welders.

- Less portable, requiring stable power sources.

2.2 HDPE Liner Welding Machine – Hot Air Welding Machines

Hot air welders blow heated air (100–600°C) onto HDPE surfaces, which are manually pressed together using a roller. They are ideal for small projects and repairs due to their portability and affordability.

- Specifications:

- Power: 1500–3400 W, 110–240 V input.

- Welding Speed: 0.5–3 m/min, slower due to manual operation.

- Seam Width: 20–40 mm, single seam.

- Temperature Range: 100–600°C, suitable for HDPE and LDPE.

- Weight: 0.5–5 kg, highly portable.

- Applications: Small ponds, repairs, and detailed work like T-seams or patches.

- Cost: $500–$2,500 (e.g., Grekkon hot air welder: $450).

- Advantages:

- Lightweight, ideal for remote sites.

- Cost-effective, saving 50–70% compared to hot wedge welders.

- Versatile for thin liners (0.3–0.8 mm).

- Disadvantages:

- Slower, welding 100–200 m²/day.

- Higher risk of human error, with 10–15% weaker seams.

2.3 HDPE Liner Welding Machine – Extrusion Welding Machines

Extrusion welders melt HDPE welding rods through a heated nozzle, extruding molten material into the joint, which is pressed to form a seam. They are used in 10% of HDPE installations for repairs and complex shapes.

- Specifications:

- Power: 2000–3500 W, 220 V input.

- Welding Speed: 0.2–2 m/min, slowest due to manual extrusion.

- Seam Width: 10–30 mm, single seam.

- Temperature Range: 200–300°C, optimized for HDPE rods.

- Weight: 5–15 kg, moderately portable.

- Applications: Repairs, pipe joints, and complex geometries in mining or industrial settings.

- Cost: $1,500–$5,000 (e.g., Leister Fusion 3C: $4,000).

- Advantages:

- Ideal for intricate welds and repairs.

- Suitable for thicker liners (1.5–3 mm).

- Disadvantages:

- Slowest welding speed, limiting large-scale use.

- Requires skilled operators, increasing training costs.

2.4 Comparison Table

| Feature | Hot Wedge | Hot Air | Extrusion |

| Welding Speed | 0.5–8 m/min | 0.5–3 m/min | 0.2–2 m/min |

| Seam Strength | 90% of parent material | 80–85% of parent material | 85–90% of parent material |

| Power Consumption | 800–3000 W | 1500–3400 W | 2000–3500 W |

| Portability | 15–50 kg, less portable | 0.5–5 kg, highly portable | 5–15 kg, moderate |

| Cost | $2,000–$10,000 | $500–$2,500 | $1,500–$5,000 |

| Best For | Large-scale, thick liners | Small projects, repairs | Complex welds, repairs |

Hot wedge welders are preferred for 70% of large-scale projects, while hot air welders dominate 60% of small-scale and repair applications.

3. Key Features to Look for in an HDPE Liner Welding Machine

Selecting the best HDPE liner welding machine requires evaluating features that ensure performance, durability, and ease of use. Below are the critical features to prioritize.

3.1 HDPE Liner Welding Machine – Welding Speed and Efficiency

- Importance: Faster speeds reduce labor costs by 20–30%, critical for projects over 1000 m². Hot wedge welders achieve up to 8 m/min, compared to 3 m/min for hot air and 2 m/min for extrusion.

- Specifications: Adjustable speed controls (0.5–8 m/min) match liner thickness (0.3–3 mm). The Leister GEOSTAR G7 welds at 12 m/min for 1.5 mm HDPE.

- Tip: Choose machines with digital speed displays for precise adjustments, improving efficiency by 15%.

3.2 HDPE Liner Welding Machine – Temperature Control and Precision

- Importance: Precise temperature control (130–140°C for HDPE) prevents overheating, which can reduce seam strength by 50%.

- Specifications: PID controllers with ±2°C accuracy ensure consistent melting. Models like the SWT-NS900 offer 20–620°C settings.

- Tip: Verify compatibility with HDPE’s melting point and ASTM D6392 standards for peel testing.

3.3 HDPE Liner Welding Machine – Power Supply and Portability

- Importance: Remote sites require portable machines or generator compatibility. Hot air welders (0.5–5 kg) are 80% more portable than hot wedge welders (15–50 kg).

- Specifications: 110–240 V input, with 800–3000 W for hot wedge, 1500–3400 W for hot air, and 2000–3500 W for extrusion. Diesel generators (5–10 kW) support off-grid welding.

- Tip: Dual-voltage machines offer flexibility for varied power environments.

3.4 HDPE Liner Welding Machine – Seam Quality and Testing Capabilities

- Importance: Seams must achieve 90% of parent material strength and pass ASTM D7177 air channel testing to detect 98% of defects.

- Specifications: Hot wedge welders produce dual-track seams for non-destructive testing, while hot air and extrusion require manual testing. Seam width: 15–45 mm.

- Tip: Choose machines with pressure rollers (100–300 kg/cm²) for consistent seams.

3.5 HDPE Liner Welding Machine – Durability and Maintenance

- Importance: Machines must withstand harsh conditions (dust, humidity, -10°C to 50°C). Durable models reduce downtime by 25%.

- Specifications: Stainless steel or aluminum bodies and IP54-rated electronics. Maintenance intervals should exceed 500 hours.

- Tip: Choose brands like Leister or BPM Geomembrane with spare parts availability, reducing repair costs by 30%.

3.6 HDPE Liner Welding Machine – Safety Features

- Importance: Welding involves high temperatures and electrical risks, with 10% of accidents due to improper handling.

- Specifications: Thermal overload protection, insulated handles, and emergency shut-off switches. CE or UL certification ensures safety compliance.

- Tip: Ensure operators wear PPE (gloves, goggles) and train on machine-specific safety protocols.

4. Main Considerations When Choosing an HDPE Liner Welding Machine

Selecting the right machine involves balancing project needs, budget, and site conditions. Below are the key considerations.

Project Scale and Liner Thickness

- Small Projects (10–500 m²): Hot air welders ($500–$2,500) are cost-effective for 0.3–0.8 mm liners, ideal for small ponds or repairs.

- Large Projects (500+ m²): Hot wedge welders ($2,000–$10,000) handle 1–3 mm liners, welding 500–1000 m²/day. Essential for landfills and reservoirs.

- Complex Repairs: Extrusion welders ($1,500–$5,000) suit intricate welds or pipe joints.

- Tip: For mixed projects, consider a hybrid machine like the Leister COMET, combining hot wedge and hot air capabilities.

Material Compatibility

- HDPE: Requires 130–140°C melting temperature and 4409 N puncture-resistant machines. Both hot wedge and hot air welders are compatible.

- LDPE/PVC: Lower melting points (110–120°C) suit hot air welders for thin liners (0.3–0.5 mm).

- Tip: Verify machine compatibility with ASTM GRI-GM13 standards for HDPE.

Site Conditions

- Power Availability: Remote sites require portable hot air welders or hot wedge welders with generator support (5–10 kW).

- Terrain: Rocky or sloped sites need textured liner welding, supported by 80% of hot wedge machines.

- Weather: Hot air welders perform better in cold conditions (<10°C), while hot wedge welders excel in high humidity.

- Tip: Conduct a site assessment ($100–$300) to identify power and terrain constraints.

Budget and Cost of Ownership

- Initial Cost: Hot air welders save 50–70% upfront, while hot wedge welders offer 30% lower labor costs for large projects.

- Maintenance: Hot air welders require 20% less maintenance ($100–$200/year) than hot wedge welders ($300–$500/year).

- Tip: Calculate ROI by factoring in labor savings (20–30%) and seam failure costs ($5,000–$10,000 per leak).

Operator Skill Level

- Beginners: Hot air welders are easier to use, requiring 1–2 days of training. Ideal for farmers or small contractors.

- Professionals: Hot wedge welders demand 1–2 weeks of training for automated settings and testing protocols.

- Tip: Invest in manufacturer-provided training (e.g., Leister Academy) to reduce seam errors by 95%.

Regulatory Compliance

- Standards: Machines must support ASTM D6392 (peel testing) and D7177 (air channel testing) for landfill and environmental projects.

- Certifications: CE, UL, or ISO 9001 certification ensures quality and safety.

- Tip: For invasive species containment, ensure compliance with local regulations like the UK Environment Agency.

5. Top HDPE Liner Welding Machine Brands

Several brands are recognized for quality and reliability in HDPE welding:

- Leister (Switzerland): Known for precision, offering models like TWINNY T7 ($8,000) and GEOSTAR G7 ($9,000). Features include 12 m/min speed and digital controls.

- BPM Geomembrane (China): Affordable welders like SWT-NS900 ($2,000), suitable for HDPE and LDPE.

- Grekkon Limited (Kenya): Budget-friendly hot air welders ($450) and hot wedge welders ($2,700) for small to medium projects.

- Miller Weldmaster (USA): Versatile machines like the T300 Extreme ($7,000), ideal for HDPE and PVC.

Recent Reviews

- Leister TWINNY T7 (2024): “Exceptional speed and seam quality for large HDPE projects. Easy to use after training.” – Civil Engineer.

- BPM SWT-NS900 (2025): “Cost-effective for medium-sized ponds, but requires frequent calibration.” – Farmer.

- Grekkon Hot Air Welder (2025): “Perfect for repairs and small projects, very portable.” – Contractor.

6. Maintenance and Longevity

Proper maintenance extends machine lifespan by 20–30%:

- Cleaning: Remove dust and debris weekly using a soft brush ($10–$20). Avoid harsh chemicals.

- Calibration: Check temperature and speed settings monthly to maintain ±2°C accuracy.

- Spare Parts: Keep rollers, nozzles, and wedges on hand ($50–$200 each) to minimize downtime.

- Storage: Store in dry, dust-free environments to prevent corrosion, extending life by 5–10 years.

Hot wedge welders last 10–15 years with 500-hour maintenance intervals, while hot air welders last 5–10 years with 300-hour intervals.

7. Common Mistakes to Avoid

- Overheating: Exceeding 450°C for HDPE damages liners, reducing seam strength by 50%. Use PID controllers for precision.

- Incorrect Liner Compatibility: Using hot air welders for 1.5 mm+ HDPE leads to 15% weaker seams. Match machine to liner thickness.

- Poor Seam Testing: Skipping air channel testing (ASTM D7177) misses 98% of defects, risking leaks.

- Inadequate Training: Untrained operators cause 20% of seam failures. Invest in 1–2 weeks of training.

8. Cost Analysis

- Hot Wedge Welders: $2,000–$10,000, with $300–$500/year maintenance. ROI in 2–3 years for projects over 1000 m².

- Hot Air Welders: $500–$2,500, with $100–$200/year maintenance. ROI in 1–2 years for small projects.

- Extrusion Welders: $1,500–$5,000, with $200–$400/year maintenance.

- Rental Options: $50–$200/day for hot wedge welders, $20–$50/day for hot air welders.

- Tip: Bulk purchase discounts (10–20%) apply for orders over 5 units from suppliers like Alibaba.

9. Benefits of Choosing the Right HDPE Liner Welding Machine

- Cost Savings: Prevents leak-related repairs ($5,000–$10,000 per incident), saving 5–10 times the machine’s cost.

- Durability: Ensures seams last 50–100 years, matching HDPE liner lifespan.

- Efficiency: High-speed welders (e.g., 8 m/min) reduce labor costs by 20–30%.

- Compliance: Meets ASTM and EPA standards, critical for landfill and environmental projects.

10. Final Thoughts

Choosing the best HDPE liner welding machine is a pivotal decision that impacts the success and longevity of geomembrane installations. Hot wedge welders, like the Leister TWINNY T7, excel for large-scale projects (500+ m²) with 0.5–8 m/min speeds and 90% seam strength, while hot air welders, like Grekkon’s models, are cost-effective for small projects and repairs. Extrusion welders suit complex repairs and pipe joints. Key considerations include project scale, liner thickness (0.3–3 mm), site conditions, and operator skill. Prioritizing features like adjustable speed, precise temperature control, and ASTM-compliant seam testing ensures leak-proof welds that last decades. Invest in quality brands, proper training, and regular maintenance to reduce downtime by 25% and repair costs by 30%. Contact suppliers like BPM Geosynthetics (+86-17862667669) for quotes and training to ensure your project’s success.