Pond liners, also known as geomembranes, are impermeable synthetic membranes essential for lining ponds, reservoirs, and other water containment structures to prevent seepage and ensure efficient water storage. These liners are critical in applications ranging from agriculture and aquaculture to landscaping and industrial projects. With water conservation becoming increasingly vital in regions like Kenya and globally, understanding the Pond Liner Price Per Square Foot is crucial for farmers, landscapers, engineers, and homeowners. This comprehensive guide delves into pond liner prices, material types, specifications, installation costs, and market trends, offering detailed insights to help you make informed purchasing decisions.

1. Factors Influencing Pond Liner Prices

The cost of pond liners per square foot varies significantly based on several key factors. Understanding these variables will help you select the right liner for your project while optimizing your budget.

1.1 Pond Liner Price Per Square Foot – Material Type

The material of a pond liner is the primary determinant of its cost, accounting for 40–60% of the total price. The most common materials include:

- High-Density Polyethylene (HDPE): HDPE Pond Liner (HDPE Geomembrane) Known for its strength, UV resistance, and chemical stability, HDPE is ideal for aquaculture, irrigation ponds, and industrial applications. Prices range from $0.62 to $1.20 per square foot in the U.S. and KSh 240–300 per square meter (approximately $0.17–$0.21 per square foot) in Kenya.

- Polyvinyl Chloride (PVC): Flexible and cost-effective, PVC liners are suitable for smaller ponds and water gardens but are less durable and not always fish-safe. They cost $0.50–$1.00 per square foot in the U.S. and KSh 200–300 per square meter ($0.14–$0.21 per square foot) in Kenya.

- Low-Density Polyethylene (LDPE): Lightweight and affordable, LDPE liners are used for small-scale or temporary projects, priced at $0.40–$0.90 per square foot in the U.S. and KSh 150–250 per square meter ($0.10–$0.17 per square foot) in Kenya.

- Ethylene Propylene Diene Monomer (EPDM): A synthetic rubber material, EPDM is highly flexible, UV-resistant, and fish-safe, ideal for decorative ponds and koi ponds. Prices range from $0.75–$2.00 per square foot in the U.S. and KSh 300–500 per square meter ($0.21–$0.35 per square foot) in Kenya.

- Reinforced Polyethylene (RPE): Lightweight and tear-resistant, RPE is suitable for large ponds and canals, costing $0.30–$1.50 per square foot in the U.S. and KSh 250–400 per square meter ($0.17–$0.28 per square foot) in Kenya.

The choice of material depends on the project’s requirements, such as water volume, environmental exposure, and budget constraints.

1.2 Pond Liner Price Per Square Foot – Thickness of the Liner

The thickness of a pond liner, measured in millimeters (mm) or mils (1 mil = 0.0254 mm), impacts its durability and price. Common thicknesses range from 0.3mm (12 mil) to 3.0mm (118 mil), with 0.5mm (20 mil) and 0.75mm (30 mil) being popular for small to medium ponds. Thicker liners are more puncture-resistant but cost more.

- 0.5mm (20 mil): Suitable for small ponds with smooth surfaces, costing $0.62–$0.80 per square foot for HDPE and $0.50–$0.65 for PVC.

- 0.75mm (30 mil): Ideal for medium ponds or fish farming, priced at $0.80–$1.20 per square foot for HDPE and $0.65–$1.00 for PVC.

- 1.0mm (40 mil): Used for large or industrial ponds, costing $1.00–$1.50 per square foot for HDPE.

- 1.5mm–3.0mm (60–118 mil): Heavy-duty applications like landfills or large reservoirs, priced at $1.50–$3.50 per square foot.

For example, a 0.5mm HDPE liner costs $0.62 per square foot, while a 1.5mm version costs $1.00–$1.20, a 10–20% increase due to added material.

1.3 Pond Liner Price Per Square Foot – Size and Dimensions of the Pond

The size of the pond directly affects the total cost, as larger projects require more material. To calculate the required liner size, use the formula:

Total Area = [Length + (2 × Depth) + 2m overlap] × [Width + (2 × Depth) + 2m overlap]

For a 10m × 15m × 2m deep pond with a 0.75mm HDPE liner at KSh 280 per square meter ($0.20 per square foot):

- Calculation: (10 + 4 + 2) × (15 + 4 + 2) = 16 × 21 = 336m²

- Total Cost: 336 × KSh 280 = KSh 94,080 ($0.20 × 3,617 sq ft = $723.40)

Online calculators from suppliers like Hortitechno Greenhouses simplify this process.

1.4 Pond Liner Price Per Square Foot – UV Resistance and Environmental Conditions

UV-treated liners, essential for sun-exposed ponds, add $0.05–$0.10 per square foot but extend lifespan by 20–30%. HDPE and RPE liners typically include UV stabilizers, while PVC liners require burial to avoid degradation, saving 10% on additives but limiting their use. In Kenya’s arid regions, UV-treated HDPE liners last 20–60 years, compared to 10–20 years for non-UV-treated PVC.

1.5 Pond Liner Price Per Square Foot – Installation and Labor Costs

Installation complexity affects costs, with professional services ranging from $0.50–$2.50 per square foot in the U.S. and KSh 50–150 per square meter ($0.03–$0.10 per square foot) in Kenya. HDPE liners require skilled welding ($0.50–$1.50 per square foot), while EPDM and PVC are easier to install ($0.20–$0.50 per square foot). Site preparation, including clearing rocks or adding geotextile underlayment, costs $0.10–$0.50 per square foot.

1.6 Pond Liner Price Per Square Foot – Supplier and Brand Reputation

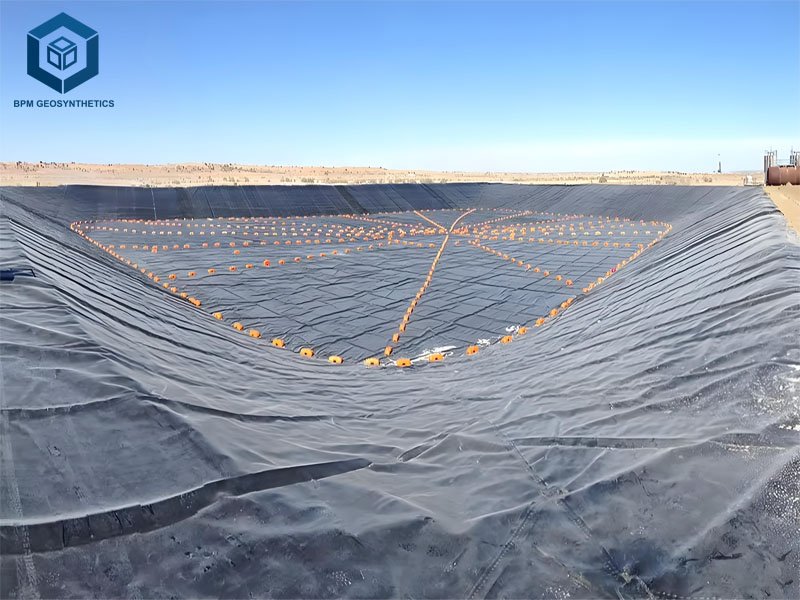

Reputable suppliers like BPM Geosynthetics, Grekkon Limited, and Aqua Hub Kenya offer virgin materials with certifications (ISO, SGS), ensuring durability and safety. Prices from trusted suppliers are 10–15% higher than lesser-known vendors but provide warranties and installation support. Recycled liners, 20% cheaper, reduce lifespan by 30% and may not be fish-safe.

1.7 Pond Liner Price Per Square Foot – Geographic Location and Market Fluctuations

Prices vary by region due to transportation costs and local demand. In Kenya, Nairobi-based suppliers may charge less than those in remote areas like Mombasa. Global oil price increases since 2022 have raised HDPE and PVC resin costs by 8%, impacting liner prices by 5–10%. Polyethylene resin prices in Q1 2025 were $1,300 per metric ton, affecting costs by 30–40%.

2. Specifications of Pond Liners

Pond liners come with specific technical specifications that influence their performance and suitability. Below are key parameters based on industry standards:

- Thickness: 0.3mm–3.0mm, with 0.5mm and 0.75mm common for small to medium ponds.

- Tensile Strength: 10–40 kN/m (ASTM D6693) for HDPE and RPE; 345–680 lbs for PVC (ASTM D7004).

- Puncture Resistance: 640 N for HDPE (ASTM D4833); 202 lbs for PVC.

- Density: 0.941–0.965 g/cm³ for HDPE, ensuring chemical stability.

- Lifespan: 10–60 years for HDPE (covered), 10–20 years for EPDM, 8–15 years for PVC.

- UV Resistance: Standard in HDPE and RPE, optional in PVC, extending lifespan by 20–30%.

- Permeability: Below 1×10⁻¹¹ cm/s, reducing leakage by 95%.

- Widths: 4m, 6m, 8m, or 15m rolls, with lengths up to 100m, reducing seams by 15%.

- Certifications: ISO 9001, SGS, and TUV for quality assurance.

These specifications make pond liners suitable for diverse applications, from small koi ponds to large irrigation reservoirs.

3. Applications of Pond Liners

Pond liners are versatile, supporting various applications based on their material and thickness.

Aquaculture

In Kenya, fish farming is a growing industry, with 500-micron HDPE liners used in ponds (1,000–30,000 sq ft) due to their fish-safe, non-toxic properties. These liners prevent seepage, maintaining stable water levels for fish growth.

Agriculture

Farmers use pond liners for irrigation ponds and canals, reducing water loss by 50–80% in porous soils. HDPE and RPE liners are preferred for large irrigation reservoirs, while PVC suits smaller canals.

Landscaping and Water Gardens

EPDM and PVC liners are ideal for decorative ponds, waterfalls, and koi ponds due to their flexibility and aesthetic appeal. They conform to irregular shapes and are fish-safe, enhancing garden aesthetics.

Industrial Applications

HDPE liners are used in wastewater treatment ponds, cooling ponds, and containment basins due to their chemical resistance, preventing groundwater contamination by 95%.

Environmental Protection

Pond liners are used in landfills and leachate ponds to prevent soil and water contamination. HDPE and RPE liners are preferred for their durability and chemical stability.

4. Price Breakdown for Pond Liners (2025)

Below is a detailed price breakdown for pond liners per square foot in the U.S. and Kenya, based on recent market data:

| Material | U.S. Price ($/sq ft) | Kenya Price (KSh/m²) | Kenya Price ($/sq ft) | Lifespan (Years) | Applications |

| HDPE | 0.62–1.20 | 240–300 | 0.17–0.21 | 10–60 | Aquaculture, irrigation, industrial |

| PVC | 0.50–1.00 | 200–300 | 0.14–0.21 | 8–15 | Water gardens, small ponds |

| LDPE | 0.40–0.90 | 150–250 | 0.10–0.17 | 8–12 | Temporary ponds, small-scale |

| EPDM | 0.75–2.00 | 300–500 | 0.21–0.35 | 10–20 | Koi ponds, landscaping |

| RPE | 0.30–1.50 | 250–400 | 0.17–0.28 | 12–35 | Large ponds, canals |

Note: Prices are approximate and may vary by supplier, location, and market fluctuations. In Kenya, 1 USD ≈ KSh 143 (June 2025). Contact suppliers like BPM Geosynthetics or Grekkon Limited for accurate quotes.

5. Installation Process and Costs

Proper installation ensures the longevity and effectiveness of a pond liner. Below is a step-by-step guide with associated costs:

5.1 Step 1: Site Preparation

- Excavation: Dig the pond to the desired shape and depth using manual tools ($100–$500) or machinery ($1,000–$5,000).

- Surface Smoothing: Remove rocks and debris to prevent punctures. Add sand or geotextile underlayment ($0.30–$1.00 per square foot), increasing lifespan by 30%.

5.2 Step 2: Liner Placement

- Unfold the liner at the pond’s center, spreading it to cover the floor and walls with a 1–2m overlap to prevent leaks.

- Anchoring: Dig a trench 1m from the edge, 30cm deep and wide, to secure the liner with soil or concrete blocks ($0.05–$0.20 per square foot).

5.3 Step 3: Welding and Sealing

- Welding: HDPE liners require hot wedge or extrusion welding ($0.50–$1.50 per square foot), while PVC and EPDM use adhesives or tape ($0.20–$0.50 per square foot).

- Testing: Fill the pond with water and monitor for leaks over 48 hours to ensure integrity.

5.4 Step 4: Additional Features

- Geotextile Underlayment: Protects against punctures, costing $0.30–$1.00 per square foot.

- Fencing: Prevents animal or debris damage, costing $50–$200 for small ponds.

- Aeration Systems: Enhance water quality for fish ponds, costing $100–$500.

5.5 Total Installation Costs

- Small Ponds (100–1,000 sq ft): $1,050–$4,400, including materials and labor.

- Medium Ponds (1,000–10,000 sq ft): $5,000–$20,000, depending on complexity.

- Large Ponds (10,000+ sq ft): $17,424–$261,360 for a 1-acre pond.

6. Market Trends and Price Fluctuations

The global pond liner market, valued at $1.45 billion in 2024, is projected to grow at a 6.8% CAGR to $2.31 billion by 2032, driven by demand for water conservation and aquaculture. Key trends include:

- Rising Resin Costs: Polyethylene resin prices rose 8% to $1,300 per metric ton in Q1 2025, increasing liner costs by 5–10%.

- Demand for UV-Treated Liners: UV-treated HDPE and RPE liners dominate in sunny regions, adding $0.05–$0.10 per square foot but extending lifespan.

- Aquaculture Growth: Fish farming in Kenya and globally has increased demand for fish-safe HDPE liners by 15% since 2023.

- Sustainability Focus: Virgin materials are preferred for safety, increasing costs by 10–20% compared to recycled options.

Prices in 2025 are expected to stabilize, but regional variations and global economic factors may cause fluctuations. Request quotes from multiple suppliers to compare prices and services.

7. Choosing the Right Pond Liner

Selecting the appropriate pond liner involves balancing cost, durability, and project requirements. Consider the following:

Project Size and Water Volume

- Small Ponds (<1,000 sq ft): PVC or LDPE liners are cost-effective for garden ponds or temporary storage.

- Medium Ponds (1,000–10,000 sq ft): HDPE or EPDM liners are ideal for aquaculture or irrigation.

- Large Ponds (10,000+ sq ft): RPE or HDPE liners suit large reservoirs or canals.

Surface Conditions

- Smooth Surfaces: 0.5mm liners suffice for sandy soils.

- Rough Terrains: Use geotextile underlayment or thicker liners (0.75mm+) to prevent punctures.

Environmental Exposure

- Sun-Exposed Areas: UV-treated HDPE or EPDM liners are essential for longevity.

- Covered Ponds: Non-UV-treated PVC or LDPE liners reduce costs by 10%.

Budget Constraints

- Low Budget: PVC or LDPE liners are affordable for short-term projects.

- Long-Term Investment: HDPE or EPDM liners offer better value due to their 20–60-year lifespan.

Supplier Reliability

Choose suppliers like BPM Geosynthetics, Grekkon Limited, or Aqua Hub Kenya, which offer certifications, warranties, and installation support. Avoid second-hand or recycled liners, as they may crack and lack warranties.

8. Maintenance and Longevity Tips

To maximize the lifespan of a pond liner, follow these maintenance tips:

- Maintain Water Coverage: Keep the pond filled to protect the liner from UV damage and physical wear.

- Regular Inspections: Check for tears or punctures every 6–12 months, costing $0.01–$0.05 per square foot annually.

- Repair Small Damages: Use patching kits or heat welding for minor tears to prevent leaks.

- Protective Fencing: Install barriers to prevent animal or debris damage, costing $50–$200.

- Geotextile Underlayment: Reduces puncture risk by 95%, costing $0.30–$1.00 per square foot.

With proper maintenance, HDPE liners can last 20–60 years, EPDM 10–20 years, and PVC 8–15 years.

9. Conclusion

The price of pond liners per square foot in 2025 ranges from $0.30 to $3.50 globally, with HDPE ($0.62–$1.20) and EPDM ($0.75–$2.00) being the most durable options, while PVC ($0.50–$1.00) and LDPE ($0.40–$0.90) offer affordability for smaller projects. In Kenya, prices range from KSh 150–500 per square meter ($0.10–$0.35 per square foot). By understanding material types, specifications, and installation requirements, you can choose a liner that meets your needs and budget. Proper installation and maintenance are crucial for maximizing lifespan, ensuring efficient water management for years to come.

For personalized quotes and expert guidance, contact trusted suppliers like BPM Geosynthetics today.