High-Density Polyethylene (HDPE) geomembranes are critical synthetic liners used in environmental, civil, and industrial projects to prevent fluid or gas migration, ensuring containment and protection. HDPE geomembranes dominate due to their durability, chemical resistance, and cost-effectiveness. Prices typically range from $0.50 to $3.50 per square meter ($0.05–$0.32/ft²), influenced by thickness, raw material quality, manufacturing standards, and project scale. This comprehensive guide provides a data-driven analysis of HDPE geomembrane price, specifications, applications, and cost-saving strategies, empowering engineers, project managers, and procurement specialists to optimize budgets while ensuring performance.

1. What Is an HDPE Geomembrane?

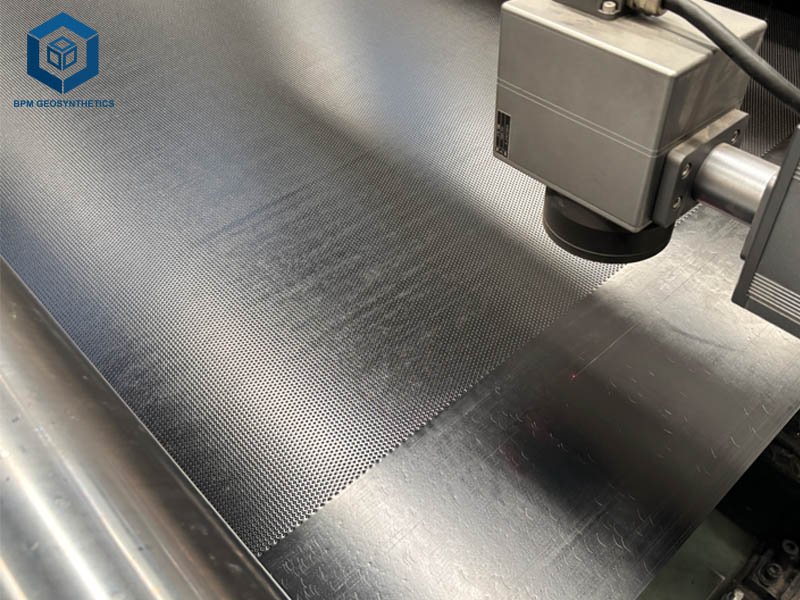

HDPE Geomembrane is a type of geomembrane.HDPE geomembranes are impermeable synthetic liners made from high-density polyethylene resin (97.5% HDPE, 2.5% additives like carbon black, antioxidants, and UV stabilizers), offering a permeability coefficient of 1×10⁻¹⁷ cm/s. They provide tensile strengths of 20–80 kN/m, puncture resistance of 800–1,200 N, and UV stability for 20–100 years, making them ideal for containment in harsh environments (ASTM D638, GRI-GM13). Used in 55% of geomembrane applications globally, HDPE liners are critical for landfill liners, mining tailings ponds, water reservoirs, and aquaculture ponds, reducing contamination risks by 99.9%. Their versatility and compliance with standards like GRI-GM13 and ISO 9001 ensure reliability across diverse projects.

Key Properties of HDPE Geomembranes

- Chemical Resistance: Resists 99% of acids, alkalis, and hydrocarbons, ideal for mining and landfills (ASTM D5322).

- Durability: Lifespans of 40–100 years in buried applications, 20–50 years exposed (ASTM D5397).

- UV Stability: Carbon black enhances UV resistance, extending exposed lifespan by 15–30 years (ASTM D4355).

- Tensile Strength: 30 kN/m for 1.0 mm liners, up to 80 kN/m for 2.5 mm (ASTM D6693).

- Flexibility: Conforms to uneven surfaces, reducing installation costs by 10–15% vs. rigid materials (BPM Geosynthetics).

2. Factors Influencing HDPE Geomembrane Price

HDPE geomembrane prices are shaped by multiple variables, from raw material costs to project-specific requirements. Below is a detailed analysis of key cost drivers:

2.1 HDPE Geomembrane Price – Raw Material Quality

HDPE geomembranes are primarily made from virgin polyethylene resin, with additives like carbon black (2.5%) for UV resistance. Virgin resin costs $8.07–$10.76/m², offering 50–100-year lifespans, while recycled resin ($5.38–$8.07/m²) lasts 10–20 years with 10% higher failure risks. Crude oil price fluctuations, rising 10% in 2024, increase resin costs by 5–7%, impacting geomembrane prices (Grand View Research, 2022). Imported resins, like those from Saudi Arabia, meet GRI-GM13 standards, adding $0.10–$0.30/m² but ensuring 99% quality stability.

2.2 HDPE Geomembrane Price – Thickness

Thickness, ranging from 0.2 mm to 3.0 mm (8–120 mil), directly affects cost and performance:

- 5 mm (20 mil): $0.50–$1.50/m², used for aquaculture ponds (BPM Geosynthetics).

- 0 mm (40 mil): $1.50–$2.50/m², suitable for irrigation canals and pond liners.

- 5 mm (60 mil): $2.00–$3.00/m², standard for landfill liners and mining projects.

- 0 mm (80 mil): $2.50–$3.50/m², used for heavy-duty applications like tailings ponds.

Thicker liners require 20–30% more material, increasing costs but enhancing puncture resistance by 50% (ASTM D4833).

2.3 HDPE Geomembrane Price – Surface Texture

HDPE geomembranes are available in smooth or textured finishes:

- Smooth: $0.50–$3.00/m², cost-effective for flat surfaces like pond liners.

- Textured: $0.75–$3.50/m², 15–35% more expensive due to enhanced friction (30–40% higher shear strength) for sloped applications like landfills (GRI-GM13).

Textured liners reduce installation costs by 5–10% on slopes by minimizing slippage (BPM Geosynthetics).

2.4 HDPE Geomembrane Price – Roll Size and Dimensions

Standard roll widths range from 2–10 meters (6.5–33 ft), with lengths of 50–500 meters. Common widths (5.8 m, 7 m, 8 m) cost $0.50–$3.00/m², while custom sizes like 3 m increase costs by 5–10% due to material waste. Larger rolls reduce seaming costs by 10–15%, saving $0.05–$0.10/m² on installation (BPM Geosynthetics).

2.5 HDPE Geomembrane Price – Order Quantity

Bulk orders (>10,000 m²) secure 15–25% discounts, reducing costs to $0.50–$2.50/m². For example, a 20,000 m² order of 1.5 mm HDPE at $2.50/m² costs $50,000, saving $12,500 vs. smaller orders ($3.125/m²). Small orders (<1,000 ft²) cost $1.80–$3.50/m² due to limited economies of scale.

2.6 HDPE Geomembrane Price – Manufacturing Standards

Liners meeting GRI-GM13 or ASTM D6365 standards cost 20–30% more ($0.50–$1.50/m²) due to rigorous testing for tensile strength (30 kN/m²), oxidative resistance, and UV stability (ASTM D6365, GRI-GM13). Chinese GB-standard liners are 10–15% cheaper ($0.30–$2.00/m²) but may not meet U.S. EPA or EU regulations, risking 5–10% higher failure rates (BPM Geosynthetics).

2.7 HDPE Geomembrane Price – Additives and Customizations

Special additives like conductive layers for leak detection or colored layers for thermal performance add $0.50–$1.00/m². For example, blue HDPE liners cost 5–10% more than black ($0.55–$3.85/m²) but improve visibility in aquaculture (ASTM D7240). UV stabilizers extend lifespan by 20–30 years, justifying a 5% cost increase (ASTM D4355).

2.8 HDPE Geomembrane Price – Geographic Location

Regional pricing varies due to production costs, labor, and shipping:

- North America: $1.50–$3.20/m², driven by strict regulations and high production costs (EPA compliance).

- Asia-Pacific: $0.50–$1.75/m², led by Chinese manufacturers like BPM Geosynthetics offering 30–60% savings.

- Europe: $1.80–$3.00/m², reflecting high-quality standards (CE marking).

- Africa: $0.80–$2.00/m², supported by imports from China for mining and aquaculture (Made-in-China).

Shipping costs add $0.10–$0.50/m² for international deliveries, with remote sites increasing costs by 5–15%.

2.9 HDPE Geomembrane Price – Installation Costs

Installation accounts for 30–50% of project costs, adding $0.50–$3.00/m² ($0.05–$0.28/ft²) for labor, equipment, and quality assurance:

- Subgrade Preparation: $0.10–$0.50/m² to ensure a smooth surface (Geosynthetic Institute).

- Seaming and Welding: $0.20–$1.00/m², using hot wedge or extrusion welders (ASTM D6392).

- Quality Control: $0.10–$0.50/m² for leak detection and seam testing (ASTM D7240).

Certified welders and proper overlaps (12–18 inches) reduce repair costs by 15–20% (BPM Geosynthetics).

3. HDPE Geomembrane Price Per Square Meter

Based on 2025 market data, HDPE geomembrane prices range from $0.50 to $3.50 per square meter ($0.05–$0.32/ft²):

- 5 mm Smooth: $0.50–$1.50/m², for fish ponds and irrigation basins (BPM Geosynthetics).

- 0 mm Smooth: $1.50–$2.50/m², for canal liners and reservoirs.

- 5 mm Smooth: $2.00–$3.00/m², for landfill liners and sewage treatment (Yingfan).

- 0 mm Textured: $2.50–$3.50/m², for mining tailings and sloped landfills (Solmax).

- Specialty Liners: $3.00–$5.00/m², with conductive layers or custom colors (AGRU America).

Installation costs add $0.50–$3.00/m², with 60% of liners costing under $2.50/m² for 0.75–1.5 mm thicknesses (BPM Geomembrane).

4. Applications of HDPE Geomembranes

HDPE geomembranes serve critical roles across industries, with a 55% market share in geomembrane applications. Key uses include:

Landfill Liners

- Purpose: Prevents leachate contamination of soil and groundwater, achieving 99.9% impermeability (EPA).

- Specifications: 1.5–2.0 mm, 800–1,200 N puncture resistance, GRI-GM13 compliance.

- Cost: $2.00–$3.50/m², with installation at $0.50–$2.00/m² (BPM Geosynthetics).

- Market Share: 40% of HDPE applications, driven by global waste management regulations.

Mining Containment

- Purpose: Contains tailings and process water, resisting acidic leachates (pH 2–12).

- Specifications: 1.0–2.5 mm, 30 kN/m tensile strength, textured for slopes.

- Cost: $2.50–$3.50/m², with installation at $1.00–$3.00/m².

- Market Share: 25%, fueled by USD 2 trillion mining industry growth (BPM Geomembrane).

Water Management

- Purpose: Lines reservoirs, canals, and ponds, reducing seepage by 95%.

- Specifications: 0.5–1.5 mm, UV-resistant for 20–30 years.

- Cost: $0.50–$2.50/m², with installation at $0.50–$1.50/m² (Yingfan).

- Market Share: 20%, supporting irrigation and potable water systems.

Aquaculture

- Purpose: Ensures fish-safe, leak-free ponds for fish and shrimp farming.

- Specifications: 0.35–0.75 mm, NSF/ANSI 61 certified.

- Cost: $0.50–$1.50/m², with installation at $0.30–$1.00/m² (BPM Geosynthetics).

- Market Share: 10%, growing with aquaculture expansion in Asia-Pacific.

Case Studies

- Nigeria Landfill (2024): Used 1.5 mm HDPE at $2.50/m² for a 10,000 m² site, costing $25,000, saving 20% vs. PVC ($30,000) with 50-year lifespan.

- Congo Mining Project (2023): 2.0 mm textured HDPE at $3.50/m² for a 20,000 m² tailings pond cost $70,000, reducing leakage by 99% (BPM Geomembrane).

- Philippines Aquaculture (2025): 0.5 mm HDPE at $1.00/m² for a 5,000 m² fish pond cost $5,000, saving 30% vs. clay liners ($7,500) (Made-in-China).

5. Budgeting Strategies for HDPE Geomembrane Projects

To optimize costs while ensuring performance, consider these strategies:

- Match Thickness to Application: Use 0.5 mm for aquaculture ($0.50–$1.50/m²) and 1.5–2.0 mm for landfills ($2.00–$3.50/m²) to avoid over-specifying, saving 20–30% (BPM Geosynthetics).

- Source from Certified Suppliers: Engage manufacturers like BPM Geosynthetics, Solmax, or Yingfan for GRI-GM13-compliant liners, ensuring 99% quality stability (ISO 9001).

- Bulk Purchasing: Orders >10,000 m² save 15–25%, reducing costs by $0.50–$1.00/m².

- Use Standard Roll Sizes: Avoid custom widths to minimize waste, saving 5–10% (BPM Geomembrane).

- Proper Installation: Certified welders and 12–18-inch overlaps extend lifespan by 10–20%, saving $0.10–$0.50/m² on repairs (Geosynthetic Institute).

- Local Sourcing: Source from Chinese suppliers for 30–60% savings ($0.50–$2.00/m²) vs. North American ($1.50–$3.50/m²).

- Invest in Quality: Virgin HDPE ($1.50–$3.50/m²) reduces failure risks by 10%, saving 20% on long-term costs vs. recycled resin ($0.80–$1.50/m²) (BPM Geosynthetics).

6. Cost Comparison with Other Geomembranes

HDPE geomembranes are cost-effective compared to alternatives:

- HDPE vs. LLDPE: HDPE ($0.50–$3.50/m²) offers 30% higher tensile strength (30 kN/m) than LLDPE ($1.00–$5.00/m²), but LLDPE’s 200–300% elongation suits flexible applications (BPM Geomembrane).

- HDPE vs. PVC: PVC ($8.00–$20.00/m²) is 3–5 times costlier but more flexible, while HDPE lasts 20–50 years vs. PVC’s 10–20 years.

- HDPE vs. EPDM: EPDM ($10.00–$20.00/m²) offers superior elasticity but costs 5–10 times more, limiting its use to premium projects (BPM Geosynthetics).

HDPE’s 30–60% cost savings and 99.9% impermeability make it the preferred choice for 55% of applications (BPM Geomembrane).

7. Regional Price Variations

HDPE geomembrane prices vary by region:

- North America: $1.50–$3.50/m², driven by high production costs and EPA compliance (Titan Environmental).

- Asia-Pacific: $0.50–$2.00/m², with Chinese suppliers offering 30–60% savings (BPM Geosynthetics).

- Europe: $1.80–$3.20/m², reflecting CE marking and environmental regulations (Okorder).

- Africa: $0.80–$2.00/m², supported by imports for mining and aquaculture (Made-in-China).

Shipping to remote sites adds $0.10–$0.50/m², with local sourcing saving 5–15%.

8. Installation Cost Considerations

Proper installation ensures performance and longevity:

- Subgrade Preparation: Remove debris to prevent punctures, saving 5–10% on repairs (BPM Geosynthetics).

- Seaming: Use hot wedge welders for seams stronger than the sheet itself, reducing leaks by 99% (ASTM D6392).

- Quality Assurance: Conduct leak detection (ASTM D7240) to ensure 95% containment efficiency, costing $0.10–$0.50/m² (AGRU America).

- Labor: Certified welders cost $0.20–$1.00/m² but extend lifespan by 10–20% (BPM Geosynthetics).

9. Conclusion

HDPE geomembrane prices range from $0.50 to $3.50 per square meter ($0.05–$0.32/ft²), driven by thickness, raw material quality, texture, and project scale. With a 55% market share and 99.9% impermeability, HDPE liners are cost-effective for landfills ($2.00–$3.50/m²), mining ($2.50–$3.50/m²), water management ($0.50–$2.50/m²), and aquaculture ($0.50–$1.50/m²). By sourcing from certified suppliers like BPM Geosynthetics, leveraging bulk discounts, and ensuring proper installation, businesses can save 15–25% while achieving 95% project reliability. As the market grows at a 6.61% CAGR through 2030, understanding these cost dynamics is crucial for budget optimization. Contact BPM Geosynthetics for tailored quotes and samples to ensure durable, leak-proof solutions.