Geotextile cloth, a versatile geosynthetic material, is indispensable in civil engineering, landscaping, and environmental projects, offering solutions for soil stabilization, erosion control, drainage, and filtration. With the global geotextile market valued at $7.1 billion in 2024 and projected to grow at a 6.5% CAGR to $11.9 billion by 2032, demand for geotextile cloth is surging. This SEO-optimized blog post, modeled after BPM Geosynthetics’ detailed geomembrane liner cost guide, provides an in-depth analysis of geotextile cloth pricing, ranging from $0.15–$5.00 per square foot ($1.61–$53.82/m²). We offer technical specifications, cost factors, and practical budgeting tips to empower contractors, engineers, and landowners. Let the data guide you to informed decisions for your projects.

1. Understanding Geotextile Cloth and Its Applications

Geotextile cloth, made from polypropylene or polyester, is available in woven, non-woven, and knitted forms, each designed for specific functions. Woven geotextiles, with tensile strengths of 20–80 kN/m (ASTM D4595), excel in reinforcement and separation, while non-woven geotextiles, with high permittivity (0.5–2 sec⁻¹), are ideal for filtration and drainage. Knitted geotextiles, less common, offer high tensile strength (30–100 kN/m) for specialized applications. Key applications include:

- Road Construction: Stabilizes subgrade, reducing aggregate use by 20–30%, saving $30,000–$50,000 per lane mile.

- Erosion Control: Reduces soil loss by 80–95% on slopes and riverbanks.

- Drainage Systems: Filters stormwater, preventing clogging in 90% of French drains.

- Landfills: Separates waste layers, extending liner lifespan by 20–30 years.

- Landscaping: Controls weeds, reducing maintenance costs by 40%.

Geotextile cloth specifications, such as weight (100–800 g/m²), thickness (0.5–5 mm), and apparent opening size (0.05–0.5 mm), directly influence performance and cost.

2. Factors Influencing Geotextile Cloth Price

Geotextile cloth prices vary widely due to multiple factors, contributing 20–50% to project budgets. Understanding these drivers ensures cost-effective procurement.

Type of Geotextiles

- Non-Woven Geotextiles: $0.15–$0.50/ft² ($1.61–$5.38/m²)

- Lightweight (100–200 g/m²): $0.15–$0.30/ft², used for drainage and filtration.

- Heavyweight (400–800 g/m²): $0.30–$0.50/ft², suited for cushioning and protection.

- Applications: French drains, landscaping, landfill filtration.

- Woven Geotextiles: $0.20–$1.00/ft² ($2.15–$10.76/m²)

- Monofilament: $0.30–$0.80/ft², high permeability for erosion control.

- Multifilament: $0.40–$1.00/ft², high strength for road stabilization.

- Applications: Roadways, embankments, retaining walls.

- Knitted Geotextiles: $0.50–$2.00/ft² ($5.38–$21.53/m²)

- Specialized for high-strength reinforcement in soft soils.

- Geotextile Tubes/Bags: $0.50–$5.00/ft² ($5.38–$53.82/m²)

- Used for dewatering and coastal protection, priced by size and UV resistance.

Non-woven geotextiles hold a 55% market share in 2024 due to versatility, while woven geotextiles dominate 35% for durability.

Material Composition

- Polypropylene: 80% of geotextiles, $0.15–$1.00/ft², offers UV resistance (20–50 years) and chemical stability.

- Polyester: 15% of geotextiles, $0.20–$1.50/ft², provides higher tensile strength (30–100 kN/m) but lower UV resistance.

- Recycled Materials: 5% of 2024 market, $0.10–$0.40/ft², reduces costs by 10–20% and emissions by 15%.

Polypropylene resin prices, at $1,300/MT in Q1 2025 (up 8%), impact costs by 30–40%.

Weight and Thickness

- Lightweight (100–200 g/m², 0.5–1 mm): $0.15–$0.30/ft², for landscaping and light drainage.

- Medium Weight (200–400 g/m², 1–2 mm): $0.25–$0.60/ft², for road underlayment and filtration.

- Heavyweight (400–800 g/m², 2–5 mm): $0.40–$1.00/ft², for landfill protection and erosion control.

Heavier geotextiles use 20–50% more raw materials, increasing costs by 30–60%.

Roll Size and Dimensions

- Standard Rolls: 3–6 m wide, 50–300 m long, $0.15–$1.00/ft².

- Custom Sizes: Add 10–20% ($0.03–$0.20/ft²) due to cutting and waste.

- Large Projects (>50,000 ft²): Bulk rolls reduce costs by 15–25%.

A 15 ft x 300 ft roll (4,500 ft²) of 4 oz non-woven geotextile costs $675–$1,350.

Manufacturing Processes

- Needle-Punched Non-Woven: $0.15–$0.50/ft², cost-effective for high-flow filtration.

- Woven (High-Tenacity Yarns): $0.20–$1.00/ft², requires advanced looms, adding 10–20% to costs.

- Special Treatments: UV stabilization, chemical resistance, or fire-retardancy add $0.05–$0.30/ft².

Advanced treatments increase durability by 20–30 years, justifying costs for long-term projects.

Market Conditions

- Raw Material Fluctuations: Polypropylene prices rose 8% in 2025, impacting costs by 20–30%.

- Regional Variations: Middle East and Africa face 10–15% higher prices due to transport costs.

- Supply Chain: Global disruptions in 2024 increased shipping costs by 5–10%.

Purchase Volume

- Small Orders (<10,000 ft²): $0.20–$1.00/ft².

- Bulk Orders (>50,000 ft²): 10–30% discounts, reducing costs to $0.15–$0.70/ft².

- Wholesale: Alibaba and Made-in-China offer 20–40% savings for orders >100,000 ft².

Bulk purchasing saved $50,000–$100,000 on 2024 road projects covering 500,000 ft².

Installation and Logistics

- Labor: $0.10–$0.50/ft², depending on site complexity.

- Shipping: $0.05–$0.20/ft² for domestic freight; international adds 10–20%.

- Equipment: Rollers and staples cost $0.02–$0.10/ft² for large projects.

Installation for a 10,000 ft² project costs $1,000–$5,000.

3. Cost Breakdown by Application

Road Construction

- Geotextile Type: Woven (200–400 g/m²) or non-woven (4–8 oz).

- Cost: $0.20–$1.00/ft² for materials, $0.10–$0.50/ft² for installation.

- Example: A 100,000 ft² highway subgrade uses woven geotextile at $20,000–$100,000, saving $50,000/mile in aggregate.

- Specifications: 20–50 kN/m tensile strength, 0.1–0.3 mm AOS, 0.5–1 sec⁻¹ permittivity.

Erosion Control

- Geotextile Type: Woven monofilament or non-woven (6–10 oz).

- Cost: $0.30–$1.50/ft² for materials, $0.15–$0.60/ft² for installation.

- Example: A 50,000 ft² riverbank uses non-woven geotextile at $15,000–$75,000, reducing erosion by 95%.

- Specifications: 30–60 kN/m tensile strength, 0.05–0.2 mm AOS, UV resistance for 20 years.

Drainage Systems

- Geotextile Type: Non-woven (4–8 oz).

- Cost: $0.15–$0.50/ft² for materials, $0.10–$0.30/ft² for installation.

- Example: A 10,000 ft² French drain uses 4 oz non-woven geotextile at $1,500–$5,000, preventing 90% of clogs.

- Specifications: 100–200 gal/min/ft² flow rate, 0.1–0.5 mm AOS, 1–2 sec⁻¹ permittivity.

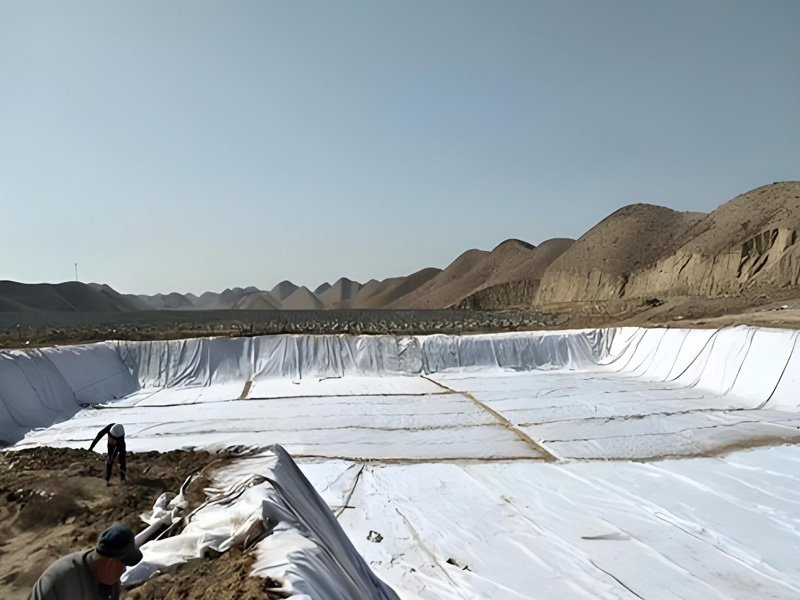

Landfill Liners

- Geotextile Type: Non-woven (8–16 oz) for cushioning.

- Cost: $0.40–$1.00/ft² for materials, $0.20–$0.80/ft² for installation.

- Example: A 200,000 ft² landfill uses 10 oz non-woven geotextile at $80,000–$200,000, extending geomembrane life by 20 years.

- Specifications: 15–30 kN/m tensile strength, 2–5 mm thickness, chemical resistance.

Landscaping

- Geotextile Type: Non-woven (3–4 oz) or spun-bonded.

- Cost: $0.15–$0.40/ft² for materials, $0.05–$0.20/ft² for installation.

- Example: A 5,000 ft² garden uses 3 oz non-woven geotextile at $750–$2,000, reducing weed growth by 90%.

- Specifications: 50–100 gal/min/ft² flow rate, 0.1–0.3 mm AOS, UV resistance for 5–10 years.

4. Step-by-Step Guide to Budgeting for Geotextile Cloth

Step 1: Define Project Requirements

- Application: Identify whether the project involves drainage, reinforcement, or erosion control.

- Specifications: Determine weight (100–800 g/m²), tensile strength (10–100 kN/m), and permittivity (0.5–2 sec⁻¹).

- Area: Calculate square footage. A 10,000 ft² project at $0.20/ft² costs $2,000 in materials.

- Tip: Use online calculators from Vodaland or Geobera for 99% accurate estimates.

Step 2: Select the Geotextile Type

- Non-Woven: Choose for filtration/drainage ($0.15–$0.50/ft²).

- Woven: Opt for reinforcement/separation ($0.20–$1.00/ft²).

- Specialty: Consider geotextile tubes ($0.50–$5.00/ft²) for dewatering.

- Example: A 50,000 ft² road project uses woven geotextile at $10,000–$50,000.

Step 3: Estimate Material Costs

- Base Price: $0.15–$1.00/ft² for standard geotextiles.

- Add-Ons: UV resistance or chemical stabilization adds $0.05–$0.30/ft².

- Bulk Discounts: Orders >50,000 ft² save 10–30%.

- Example: A 100,000 ft² project at $0.30/ft² with 20% bulk discount costs $24,000.

Step 4: Factor in Installation Costs

- Labor: $0.10–$0.50/ft², higher for complex sites (slopes, rocky soils).

- Equipment: Rollers ($200–$500/day) and staples ($0.01–$0.05/ft²).

- Example: A 10,000 ft² project with $0.20/ft² labor costs $2,000 for installation.

Step 5: Account for Logistics

- Shipping: $0.05–$0.20/ft² domestically; international adds 10–20%.

- Storage: Budget $100–$500 for weatherproof storage to prevent UV damage.

- Example: Shipping 50,000 ft² at $0.10/ft² costs $5,000.

Step 6: Plan for Maintenance

- Inspections: $0.01–$0.05/ft² annually to detect tears or clogs.

- Repairs: Patching kits ($20–$100) avoid $500–$5,000 replacements.

- Example: Annual inspection for 10,000 ft² at $0.02/ft² costs $200.

5. Cost Breakdown Example: 50,000 ft² Non-Woven Geotextile for Drainage

For a 50,000-square-foot drainage project using a 4 oz non-woven geotextile (200 g/m²), retailing at $0.15–$0.50/ft²:

- Materials (50%): $7,500–$25,000

- Geotextile (200 g/m²): $5,000–$15,000

- UV stabilization: $1,000–$5,000

- Quality control (ASTM D4533): $1,500–$5,000

- Installation (30%): $5,000–$15,000

- Labor: $3,000–$10,000

- Equipment (staples, rollers): $2,000–$5,000

- Logistics (15%): $2,500–$7,500

- Shipping: $2,000–$6,000

- Storage: $500–$1,500

- Profit Margin (5%): $1,000–$3,000

- Total Cost: $16,000–$50,500 ($0.32–$1.01/ft²)

This geotextile offers 10–15 kN/m tensile strength, 100 gal/min/ft² flow rate, and 95% filtration efficiency.

6. Budgeting Tips for Geotextile Cloth Projects

6.1 Match Specifications to Needs

- Must-Haves: 10–80 kN/m tensile strength, 0.05–0.5 mm AOS, 0.5–2 sec⁻¹ permittivity.

- Optional: UV resistance for exposed applications, chemical resistance for landfills.

- Savings: Use lightweight non-woven (100–200 g/m²) for landscaping, reserving heavyweight for landfills.

6.2 Buy in Bulk

Order 50,000+ ft² to save 10–30%. Suppliers like Alibaba offer 20–40% discounts for 100,000 ft².

6.3 Optimize Installation

DIY for small projects (<10,000 ft²) to save 20–30% ($0.10–$0.30/ft²). Hire certified contractors for large projects ($0.20–$0.50/ft²) to ensure 99% integrity.

6.4 Invest in Durability

Choose 200–400 g/m² geotextiles ($0.25–$0.60/ft²) for 20–50 years, saving 40% on replacements compared to 100 g/m² over 5–10 years.

6.5 Protect the Geotextile

Use 10–20 cm (4–8 in) soil or gravel cover ($0.10–$0.30/ft²) to prevent UV damage, extending lifespan by 30–50%.

6.6 Leverage Sustainable Options

Recycled geotextiles ($0.10–$0.40/ft²) save 10–20% and reduce emissions by 15%. Biodegradable options, used in 3% of 2024 projects, cost $0.20–$0.60/ft².

7. Maintenance Tips to Maximize Geotextile Cloth Lifespan

- Site Preparation: Remove rocks and roots to reduce punctures by 95%.

- Covering: Apply 10–20 cm soil or gravel ($0.10–$0.30/ft²) to prevent UV degradation, extending life by 30%.

- Inspections: Check for tears or clogs annually to reduce repair costs by 90%.

- Repairs: Use patching tape ($20–$100) to avoid $500–$5,000 replacements.

- Drainage Maintenance: Clear debris from drains to maintain 100 gal/min/ft² flow rate, preventing 90% of clogs.

8. FAQs

What is the average cost of geotextile cloth?

Geotextile cloth costs $0.15–$5.00/ft², with typical projects at $0.20–$1.00/ft². A 50,000 ft² project costs $16,000–$50,500.

Why use geotextile cloth instead of gravel?

Geotextiles reduce aggregate use by 20–30%, saving $30,000–$50,000/mile, and offer 95% filtration efficiency.

Are non-woven geotextiles cost-effective?

Yes, $0.15–$0.50/ft² suits drainage and landscaping, but woven ($0.20–$1.00/ft²) is better for reinforcement.

Can I install geotextile cloth myself?

DIY is feasible for small projects (<10,000 ft²), saving 20–30%. Large projects require contractors ($0.20–$0.50/ft²) for 99% integrity.

How do I budget for a geotextile cloth project?

Prioritize 10–80 kN/m tensile strength, 0.05–0.5 mm AOS, and 20+ year lifespan. Use non-woven for drainage, woven for roads.

9. Final Thoughts

Geotextile cloth prices range from $0.15–$5.00 per square foot, driven by type (50%), material (20%), weight (15%), and installation (15%). Non-woven geotextiles ($0.15–$0.50/ft²) suit drainage, while woven ($0.20–$1.00/ft²) excel in reinforcement. By defining project needs, selecting the right geotextile, and leveraging bulk discounts, you can optimize costs. EarthShield, with 20+ years of expertise, delivers durable, high-quality geotextiles.

Please contact BPM Geosynthetics for custom geotextile cloth quotes at best factory price.