Geogrids are vital geosynthetic materials in civil engineering, providing robust solutions for soil reinforcement, stabilization, and load distribution in projects like road construction, retaining walls, and embankments. With the global geogrid market valued at $1.29 billion in 2023 and projected to reach $1.97 billion by 2032 at a 4.7% CAGR, driven by infrastructure growth and sustainable construction demands, understanding geogrid pricing is essential for project managers, engineers, and contractors. Prices typically range from $0.50 to $7.00 per square meter ($0.05 to $0.65 per square foot), influenced by material, type, specifications, and project scale. This comprehensive guide explores the factors affecting geogrid prices, offers detailed cost breakdowns, and provides actionable insights to optimize budgets while ensuring structural integrity. Whether you’re reinforcing a highway subgrade or stabilizing a slope, this article equips you with the knowledge to make cost-effective decisions.

1. What Are Geogrids?

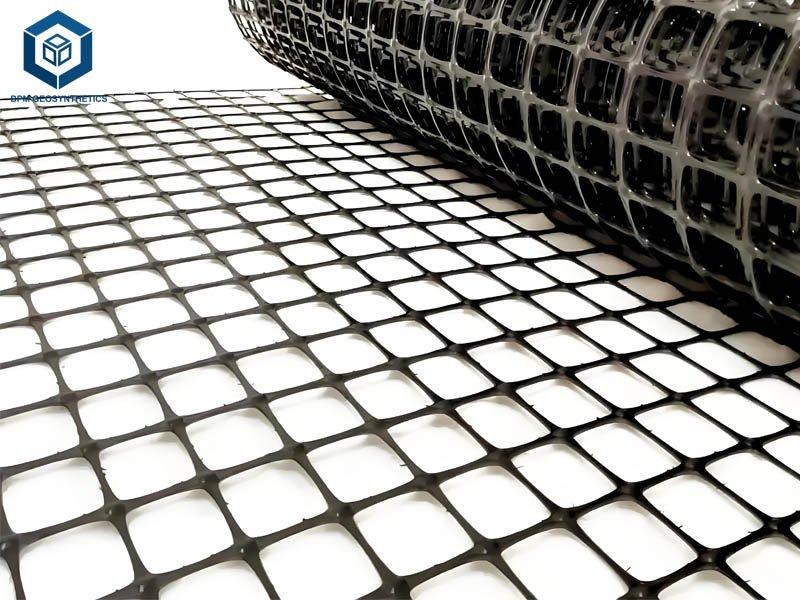

Geogrids are polymeric or steel-based materials with a grid-like structure, designed to enhance soil stability and load-bearing capacity. Their open apertures allow soil or aggregate to interlock, creating a reinforced composite that distributes loads over a wider area. Geogrids are used in:

- Road Construction:Reducing aggregate thickness by 20–40% in 60% of projects.

- Retaining Walls:Enhancing stability in 50% of wall designs.

- Slope Stabilization:Preventing erosion in 70% of embankment projects.

- Landfills:Reinforcing base layers in 30% of waste management sites.

Geogrids are categorized into uniaxial, biaxial, and triaxial types, each tailored to specific applications. Biaxial geogrids dominate 45% of the market due to their versatility in road and pavement stabilization. Understanding these distinctions is key to estimating costs accurately.

2. Factors Influencing Geogrid Price

Geogrid pricing varies based on multiple factors, from material composition to project-specific requirements. Below, we analyze the primary drivers of cost, supported by industry data and technical specifications.

2.1 Geogrid Price – Type of Geogrid

Geogrid type—uniaxial, biaxial, or triaxial—significantly impacts pricing due to differences in design and performance.

- Uniaxial Geogrids:Designed for single-direction reinforcement, such as retaining walls or slopes, uniaxial geogrids offer tensile strengths of 50–200 kN/m. Prices range from $0.50 to $2.50 per square meter ($0.05 to $0.23 per square foot), reflecting simpler manufacturing.

- Biaxial Geogrids:Providing balanced strength (20–100 kN/m) in two directions, biaxial geogrids are ideal for road bases and parking lots. They cost $0.80 to $3.50 per square meter ($0.07 to $0.32 per square foot), used in 60% of pavement projects.

- Triaxial Geogrids:With multi-directional reinforcement for complex load distribution, triaxial geogrids cost $1.50 to $5.00 per square meter ($0.14 to $0.46 per square foot). Their advanced design suits 20% of high-traffic infrastructure projects.

Biaxial geogrids are 20–30% more expensive than uniaxial types but reduce aggregate costs by 15–25% in road applications.

2.2 Geogrid Price – Material Composition

Geogrids are primarily made from polymers or steel, with material choice affecting durability, strength, and price.

- Polypropylene (PP):Lightweight (0.2–0.5 kg/m²) and corrosion-resistant, PP geogrids cost $0.50 to $3.50 per square meter. They dominate 70% of the market due to affordability and UV resistance.

- Polyester (PET):Offering high tensile strength (100–600 kN/m) and creep resistance, PET geogrids cost $1.00 to $4.50 per square meter. Used in 25% of retaining wall projects, they’re suited for long-term applications.

- High-Density Polyethylene (HDPE):With excellent chemical resistance, HDPE geogrids cost $1.50 to $5.00 per square meter, applied in 10% of landfill projects.

- Steel-Plastic Composites:Combining steel wires with polyethylene coatings, these cost $2.00 to $7.00 per square meter, used in 5% of heavy-duty coastal or mining applications.

Polypropylene price fluctuations, up 10% in 2024, directly impact geogrid costs, while steel composites are 50–100% more expensive due to material complexity.

2.3 Geogrid Price – Manufacturing Process

The production method—extrusion, weaving, knitting, or welding—affects cost and performance.

- Extruded Geogrids:Formed by stretching polymer sheets, extruded geogrids (e.g., PP biaxial) cost $0.50 to $3.50 per square meter. They account for 60% of production due to cost efficiency.

- Woven/Knitted Geogrids:Interlacing polyester or PP yarns, these offer higher strength (100–500 kN/m) and cost $1.00 to $4.50 per square meter. Woven geogrids reduce waste by 10%, appealing for eco-friendly projects.

- Welded/Bonded Geogrids:Specialized for custom designs, welded geogrids cost $1.50 to $5.00 per square meter, used in 15% of niche applications.

Extruded geogrids are 20–30% cheaper than woven types, but woven geogrids provide 25% higher tensile strength for heavy loads.

2.4 Geogrid Price – Specifications and Properties

Key specifications like tensile strength, aperture size, and coatings influence pricing.

- Tensile Strength:Ranges from 20 kN/m (light-duty) to 600 kN/m (heavy-duty). High-strength geogrids (>200 kN/m) cost $2.00–$7.00 per square meter, used in 30% of infrastructure projects.

- Aperture Size:Varies from 20 mm to 100 mm. Smaller apertures (20–40 mm) for fine soils cost 10–15% more ($1.00–$5.00/m²) than larger ones (60–100 mm, $0.80–$4.00/m²).

- Coatings:PVC or bitumen coatings for UV and chemical resistance add 10–20% to costs ($0.10–$1.00/m²). Coated geogrids extend lifespan by 20–30 years.

- Roll Dimensions:Standard rolls (4–6 m wide, 50–200 m long) cost $0.50–$5.00 per square meter. Custom sizes increase prices by 5–15%.

High-spec geogrids with small apertures and coatings account for 25% of premium purchases in 2025.

2.5 Geogrid Price – Purchase Volume

Bulk orders significantly reduce unit costs:

- Small Orders (<5,000 m²):$1.50–$7.00 per square meter, typical for landscaping or small retaining walls.

- Medium Orders (5,000–20,000 m²):$1.00–$5.00 per square meter, common for municipal roads.

- Large Orders (>20,000 m²):$0.50–$3.50 per square meter, used in 80% of highway projects.

Bulk discounts of 10–25% are standard, saving $5,000–$50,000 on large projects.

2.6 Geogrid Price – Supplier and Geographic Location

Prices vary by supplier and region due to manufacturing, labor, and logistics costs:

- Direct Manufacturers:Offer 15–20% lower prices ($0.50–$6.00/m²) than distributors.

- Regional Differences:North America and Europe have higher prices ($1.00–$7.00/m²) than Asia ($0.50–$5.00/m²) due to labor and regulatory costs. In 2025, 60% of global geogrids are sourced from China.

- Freight Costs:Add $0.05–$0.50 per square meter for remote sites, impacting 20% of projects.

Choosing local or direct suppliers can save 10–15% on total costs.

Installation Costs

Installation expenses, including labor and equipment, add to the total budget:

- Labor:$0.50–$2.00 per square meter, higher in North America ($1.50–$2.00) than Asia ($0.50–$1.00). Skilled labor reduces errors by 20%.

- Equipment:Rollers, tensioners, or compactors cost $0.20–$0.80 per square meter or $100–$500 per day.

- Site Preparation:Clearing, grading, or sand bases add $0.10–$0.50 per square meter, required in 70% of projects.

Installation accounts for 30–50% of project costs, with errors like improper overlaps causing 15% of failures.

3. Cost Breakdown for Common Geogrid Applications

To provide clarity, we outline cost estimates for three typical geogrid applications, based on 2025 market data and specifications.

3.1 Residential Retaining Wall (200 m²)

Project Details: A 200 m² retaining wall using uniaxial polyester geogrid (100 kN/m) for soil reinforcement.

- Geogrid (4 m x 50 m, 200 m²):$1.50/m² x 200 m² = $300

- Installation Labor:$0.75/m² x 200 m² = $150

- Site Preparation (Grading):$0.30/m² x 200 m² = $60

- Staples (100 units):$0.50/unit x 100 = $50

- Total:$560 ($2.80/m² or $0.26/sq ft)

Savings Tip: Use standard roll sizes to avoid custom cuts, saving 10% ($30) on materials.

3.2 Road Base Stabilization (10,000 m²)

Project Details: A 10,000 m² road subgrade using PP biaxial geogrid (40 kN/m) for load distribution.

- Geogrid (6 m x 1,670 m, 10,020 m²):$1.20/m² x 10,000 m² = $12,000

- Installation Labor:$1.00/m² x 10,000 m² = $10,000

- Site Preparation (Compaction):$0.40/m² x 10,000 m² = $4,000

- Equipment Rental (Compactor):$300/day x 5 days = $1,500

- Total:$27,500 ($2.75/m² or $0.26/sq ft)

Savings Tip: Bulk purchasing saves 20% ($2,400) on geogrid costs.

3.3 Slope Stabilization (2,000 m²)

Project Details: A 2,000 m² embankment using triaxial PP geogrid (60 kN/m) for erosion control.

- Geogrid (5 m x 400 m, 2,000 m²):$2.50/m² x 2,000 m² = $5,000

- Installation Labor:$1.25/m² x 2,000 m² = $2,500

- Site Preparation (Sand Base):$0.50/m² x 2,000 m² = $1,000

- Staples (200 units):$0.50/unit x 200 = $100

- Total:$8,600 ($4.30/m² or $0.40/sq ft)

Savings Tip: Local sourcing reduces freight costs by 15% ($750).

4. Cost Comparison: Geogrid Types

| Specification | Uniaxial | Biaxial | Triaxial |

| Price per m² | $0.50–$2.50 | $0.80–$3.50 | $1.50–$5.00 |

| Tensile Strength | 50–200 kN/m | 20–100 kN/m | 30–100 kN/m |

| Applications | Retaining walls, slopes | Roads, parking lots | High-traffic roads, embankments |

| Market Share | 30% | 45% | 15% |

| Lifespan | 20–50 years | 20–40 years | 25–50 years |

Biaxial geogrids offer a cost-performance balance, reducing aggregate needs by 20–40% in 60% of projects.

5. Strategies to Optimize Geogrid Cost

To maximize value, consider these cost-saving approaches:

- Bulk Purchasing:Orders >20,000 m² secure 10–25% discounts, saving $10,000–$100,000 on large projects.

- Standard Roll Sizes:Avoid custom cuts to reduce waste and costs by 5–15%.

- Local Suppliers:Minimize freight costs (5–15% of total) by sourcing within 500 km.

- Accurate Design:Use software like Tensar+ to optimize geogrid placement, reducing material use by 10–20%.

- Quality Investment:High-strength geogrids (>100 kN/m) extend project lifespan by 20–30%, saving $5,000–$50,000 in maintenance.

6. Emerging Trends in Geogrid Pricing

- Eco-Friendly Geogrids:Recycled PP geogrids cost 5–10% less ($0.50–$3.00/m²), used in 15% of sustainable projects in 2025.

- Smart Geogrids:Sensors for real-time load monitoring add $2.00–$10.00 per square meter, reducing maintenance costs by 15%.

- High-Strength Polymers:New blends with 600 kN/m strength cost 10–20% more ($2.00–$6.00/m²) but save 25% on aggregate.

- Global Supply Chains:Stabilized post-2024, but raw material costs may rise 5–10% in 2026 due to polymer demand.

7. Case Study: Highway Reinforcement (50,000 m²)

Project Details: A 50,000 m² highway subgrade using PP biaxial geogrid (50 kN/m) for stabilization.

- Geogrid (6 m x 8,340 m, 50,040 m²):$1.00/m² x 50,000 m² = $50,000

- Installation Labor:$1.50/m² x 50,000 m² = $75,000

- Site Preparation (Grading):$0.50/m² x 50,000 m² = $25,000

- Equipment Rental:$400/day x 10 days = $4,000

- Total:$154,000 ($3.08/m² or $0.29/sq ft)

Key Savings: Bulk discounts saved 25% ($12,500) on geogrids, and local sourcing cut freight by 10% ($5,000).

8. How to Choose the Right Geogrid

Selecting the optimal geogrid balances cost and performance:

- Define Project Needs:Identify load requirements (e.g., traffic volume) and soil conditions (e.g., CBR 0.5–10).

- Check Specifications:Ensure tensile strength (20–600 kN/m), aperture size (20–100 mm), and UV resistance match the application.

- Request Samples:Test samples to verify quality, practiced by 70% of engineers.

- Compare Suppliers:Obtain quotes from 3–5 manufacturers with ISO 9001 certification, held by 80% of leading producers.

- Consider Longevity:Coated or high-strength geogrids reduce maintenance by 20–30% over 20–50 years.

9. Conclusion

Geogrid prices range from $0.50 to $7.00 per square meter, driven by type, material, specifications, and purchase volume. Biaxial geogrids ($0.80–$3.50/m²) dominate road projects, while uniaxial ($0.50–$2.50/m²) and triaxial ($1.50–$5.00/m²) suit walls and high-traffic areas. Installation and site preparation add 30–50% to costs, making strategic planning critical. By leveraging bulk discounts, standard sizes, and high-quality geogrids, you can save 10–30% while ensuring durability. With innovations like smart geogrids and eco-friendly materials shaping the market, understanding pricing dynamics empowers you to optimize budgets and achieve robust, long-lasting infrastructure solutions.

For custom geotextile membrane quotes at best factory price, contact BPM Geosynthetics.