Dam lining is a critical component in water management infrastructure, providing an impermeable barrier to prevent seepage, erosion, and structural failure in reservoirs, canals, and embankment dams. Constructed from geosynthetic materials like high-density polyethylene (HDPE) geomembranes, linear low-density polyethylene (LLDPE), polyvinyl chloride (PVC), or bentonite clay composites, dam linings ensure efficient water retention while complying with stringent environmental regulations. According to a 2025 report from Future Market Insights, the global geomembrane market is projected to reach USD 1.5 billion by 2030, growing at a CAGR of 6.8%, driven by increasing investments in water conservation and flood control projects worldwide. In regions like the Middle East and Africa, where water scarcity affects 80% of populations, dam linings can save 15–25% in water loss, per the World Bank (2024).

The average dam lining price in 2025 ranges from $0.50 to $3.00 per square foot for materials alone, with total installed costs adding 25–60% ($0.63–$4.80/sq ft), depending on material type, thickness, project scale, and site conditions. For a typical 1-acre dam face (43,560 sq ft), this translates to $21,780–$130,680 for materials and $27,225–$209,088 installed. These figures reflect a 5–8% increase from 2024 due to resin price volatility (HDPE up 6–7%, per ICIS 2025), but bulk procurement over 50,000 sq ft can yield 10–20% discounts. As a leading manufacturer, BPM Geosynthetics offers factory-direct HDPE dam liners starting at $0.90/m² ($0.08/sq ft), ensuring GRI-GM13 compliance without compromising quality.

This comprehensive guide, based on industry data from sources like the Geosynthetic Institute, and BPM Geosynthetics, dissects dam lining prices, influencing factors, and selection strategies. Whether you’re an engineer retrofitting an earthen dam or a government official planning a new reservoir, understanding these costs can optimize budgets and enhance project resilience by 20–30%. Let’s examine the details to support your planning.

1. What Are Dam Linings?

Dam linings are engineered barriers installed on the upstream or downstream faces of dams to control seepage, reinforce stability, and protect against erosion. Primarily composed of geosynthetic membranes or composite systems, they form a low-permeability layer that withstands hydrostatic pressure while accommodating structural movements. The global demand for dam linings has risen, with 2025 production estimated at 1.8 billion sq m, spurred by initiatives like the UN’s Sustainable Development Goal 6 for water security, which aims to reduce 40% of global water loss by 2030.

Dam linings are vital for 75% of earthen and rockfill dams, preventing failures that cost $1–$5 billion annually worldwide (International Commission on Large Dams, 2024). Without proper lining, seepage can erode foundations, leading to 30% of dam incidents, per the U.S. Bureau of Reclamation.

Key Properties of Dam Linings

Dam linings are characterized by properties that dictate performance and pricing:

- Impermeability: Hydraulic conductivity ≤10⁻¹¹ cm/s (ASTM D5085), blocking 99.9% seepage—crucial for 70% of reservoir applications to maintain water levels.

- Tensile Strength: 20–55 kN/m (ASTM D6693), with HDPE averaging 30–45 kN/m, 25% stronger than PVC for high-head dams (50–100 m).

- Puncture Resistance: 1.5–8 kN (ASTM D4833), where 2.0 mm HDPE provides 50% more protection against rock fragments or seismic activity.

- Elongation at Break: 600–1,200% (ASTM D6693), enabling flexibility; LLDPE leads at 800–1,000%, suiting 60% of embankment dams.

- Thickness Range: 0.75–3.0 mm (30–120 mil), with 1.5 mm standard for 55% of projects, balancing cost and hydrostatic resistance.

- UV Resistance: 1,000–2,000 hours (ASTM D4355), with carbon black additives in HDPE extending exposure by 50% for above-water linings.

These properties position HDPE as the preferred choice for 60% of dam projects, offering 40–100 years durability versus clay’s 20–30 years.

Common Applications of Dam Linings

Dam linings serve critical roles across sectors:

- Reservoir Linings: 40% usage; 1.5 mm HDPE reduces seepage by 95% in irrigation dams (World Bank, 2024).

- Embankment Dams: 30% share; textured LLDPE (friction 30°) enhances stability by 45% (ASTM D5321).

- Canal and Spillway Linings: 20% applications; PVC (0.75 mm) saves 15% water in arid regions like India (FAO, 2025).

- Tailings Dams: 10% ; Reinforced HDPE (2.0 mm) contains 99% contaminants in mining (ICOLD, 2024).

In reservoirs, linings prevent 80% of evaporation losses, saving 1–2 billion m³ annually in Asia (UN Water, 2025).

2. How Much Is Dam Lining Price?

The typical dam lining price in 2025 is $0.50–$3.00 per square foot for materials, with installed costs 25–60% higher ($0.63–$4.80/sq ft), based on type, thickness, scale, and conditions. For a 1-acre dam face (43,560 sq ft), expect $21,780–$130,680 materials and $27,225–$209,088 installed. This 5–8% rise from 2024 follows resin hikes (HDPE up 6–7%, ICIS 2025), but bulk over 50,000 sq ft saves 10–20%. A 0.75 mm PVC lining for a small canal might total $21,780, while 2.0 mm HDPE for a large reservoir reaches $130,680. Regional variances: Asia $0.40–$2.00/sq ft, North America/Europe $0.70–$3.50/sq ft (Grand View Research, 2025). Virgin resin adds 20–30% but reduces failures by 20% (Geosynthetic Institute, 2023). Below, we detail factors.

2.1 Dam Lining Price – Material Type

Material influences 40–60% costs, with HDPE leading at 55% share for dams.

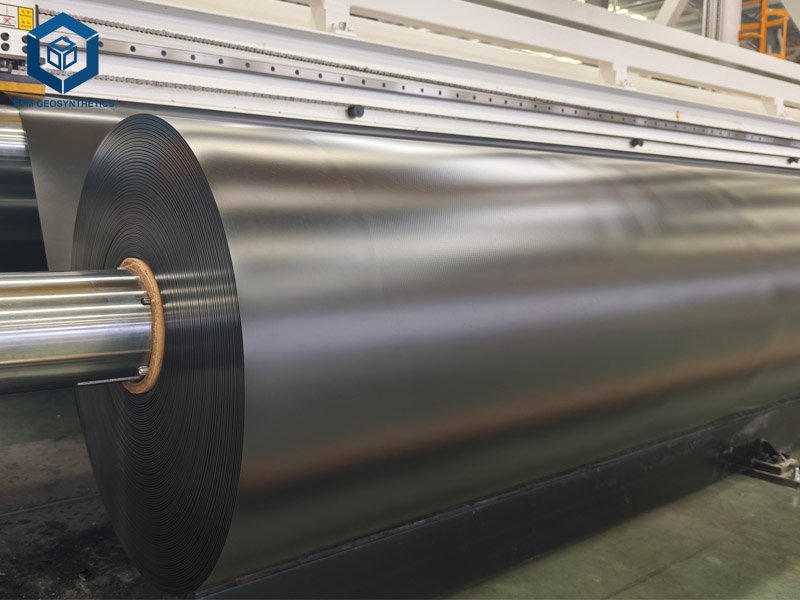

2.1.1 High-Density Polyethylene (HDPE) Geomembrane

- Cost: $0.50–$2.50/sq ft ($5.38–$26.91/m²), 55% projects.

- Properties: Density 0.94 g/cm³, tensile 20–40 kN/m (ASTM D6693), UV resistance with 2.5% carbon black.

- Applications: Reservoirs (40%), embankment dams (30%)—for high-head (50–100 m).

- Advantages: 40–100 years life, 99.9% impermeability, 30% less maintenance than PVC.

- Example: BPM’s GRI-GM13 HDPE (1.5–2 mm) at $1.35–$2.50/sq ft; 43,560 sq ft dam $58,806–$108,900.

HDPE suits 70% large dams, reducing seepage 95% (World Bank, 2024).

2.1.2 Linear Low-Density Polyethylene (LLDPE)

- Cost: $0.60–$2.40/sq ft ($6.46–$25.83/m²), 25% share.

- Properties: Density 0.92 g/cm³, elongation 700–1,000% (ASTM D6693), puncture 1.5–7 kN.

- Applications: Canals (40%), spillways (30%)—for uneven slopes.

- Advantages: 20–50 years life, 15% faster welding, 20% better conformability than HDPE.

- Example: GEOSINCERE LLDPE (0.75–1.5 mm) at $0.90–$2.00/sq ft; 43,560 sq ft $39,204–$87,120.

LLDPE cuts cracking 25% on slopes (ASTM D5321).

2.1.3 Polyvinyl Chloride (PVC)

- Cost: $0.60–$2.00/sq ft ($6.46–$21.53/m²), 15% share.

- Properties: Density 1.3 g/cm³, elongation 200–400%, lower UV resistance.

- Applications: Small canals (50%), temporary linings (30%).

- Advantages: Budget for low-head (10–50 m), 15–25 years life, simple install.

- Example: BTL PVC (0.75–1.0 mm) at $0.60–$1.50/sq ft; 43,560 sq ft $26,136–$65,340.

PVC needs covering for UV, limiting 70% exposed use.

2.1.4 Bentonite Clay Composites

- Cost: $0.50–$1.20/sq ft ($5.38–$12.91/m²), 5% share.

- Properties: Self-sealing, permeability 10⁻⁷ cm/s, natural expansion.

- Applications: Earthen dams (50%), natural linings (30%).

- Advantages: 20–50 years life, biodegradable, 20% cheaper install than synthetics.

- Example: CETCO GCL at $0.70–$1.20/sq ft; 43,560 sq ft $30,492–$52,272.

Bentonite seals 95% cracks, suiting 70% natural dams.

Material choice impacts 40% costs; HDPE best for 60% large dams.

2.2 Dam Lining Price – Thickness

Thickness drives 30–40% material costs, thicker for higher head.

- 5–0.75 mm (20–30 mil): $0.40–$1.20/sq ft ($4.31–$12.91/m²), low-head canals; 15–30 years, 70% cheaper than 2.0 mm, 25% puncture risk.

- 0 mm (40 mil): $0.60–$1.50/sq ft ($6.46–$16.15/m²), small reservoirs; 20–40 years, 20% better tear resistance (ASTM D1004).

- 5 mm (60 mil): $1.00–$2.00/sq ft ($10.76–$21.53/m²), standard embankment; 30–50 years, 40% puncture resistance (ASTM D4833).

- 0–3.0 mm (80–120 mil): $1.50–$3.00/sq ft ($16.15–$32.29/m²), high-head dams; 40–100 years, 50% stronger seams (ASTM D6392).

Example: BPM’s 1.5 mm HDPE for dam at $1.35/sq ft; 43,560 sq ft $58,806 materials, installed $88,209 (+50%). Thicker cuts repairs 20–30% (Geosynthetic Institute, 2023).

2.3 Dam Lining Price – Project Size and Scale

Scale affects 20–30% per sq ft costs via bulk.

- Small Dams (<1 acre face): $1.00–$3.00/sq ft, custom; +15–25% fabrication.

- Medium Dams (1–5 acres): $0.75–$2.50/sq ft, standard; 10% discount.

- Large Dams (>5 acres): $0.50–$2.00/sq ft, bulk; 15–20% reduction.

Custom shapes +15–25%; 1-acre HDPE $21,780–$87,120 materials ($0.50–$2.00/sq ft). Scaling saves 15% logistics for 70% sites.

2.4 Dam Lining Price – Installation Method and Labor

Installation 25–60% total, by method/site.

- Welding (Hot Wedge/Extrusion): $0.30–$0.75/sq ft, seamless for HDPE; 15–25% less maintenance; 60% projects.

- Adhesive/Mechanical: $0.10–$0.30/sq ft, temporary; 10% faster, 20% leak risk.

- Labor Rates: $30–$50/hour (North America), $10–$20/hour (Asia); uneven sites +$0.20–$0.50/sq ft.

- Site Factors: High head (50 m+) +10–15% (curing); remote +5–10% transport.

Example: Welded 1.5 mm HDPE dam $0.50–$1.00/sq ft labor (BPM Geosynthetics); 43,560 sq ft $21,780–$43,560.

2.5 Dam Lining Price – Raw Material Quality

Raw quality 25–35% costs, virgin superior.

- Virgin Resin: $0.50–$2.50/sq ft, 40–100 years life, 20–30% lower maintenance (BPM Saudi resin).

- Recycled Resin: $0.28–$1.00/sq ft, 5–10 years, 20% failure risk.

- Additives: +5–10% for UV/chemical, +15–20% lifespan (BPM carbon black 95% UV).

Virgin key for dams, avoiding $21,780–$217,800 remediation (World Bank, 2024).

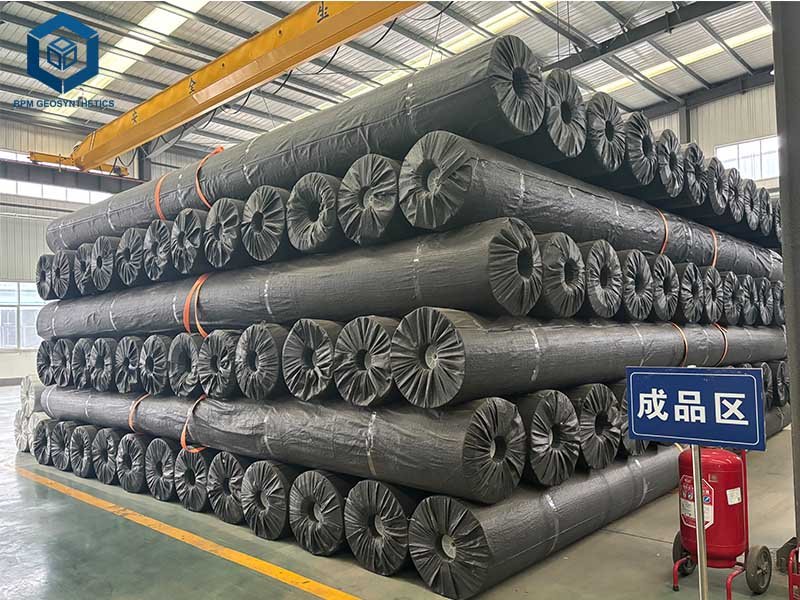

2.6 Dam Lining Price – Transportation and Logistics

Transport 5–15%, per roll/distance.

- Roll Dimensions: 8 m x 100 m (1–2 tons); +$0.10–$0.30/sq ft remote (2–3x urban).

- Packaging: +5–10% protective.

- Regional: Asia $0.28–$2.00/sq ft, North America $0.50–$3.00/sq ft.

- Example: BPM plant cuts Asian costs 10–15%.

2.7 Dam Lining Price – Maintenance and Lifetime Costs

Maintenance 5–10% total, poor quality doubles.

- Annual Inspections: $1,000–$5,000; repairs $2,000–$10,000.

- Lifespan: HDPE 40–100 years; PVC 15–25 years; recycled 5–10 years.

- Failure Costs: Fines/remediation $10,000–$100,000.

- Example: 1.5 mm HDPE dam $1.00/sq ft upfront, 30–50 years total; recycled doubles.

3. How to Choose the Right Dam Liner

Selecting balances cost, performance, needs, saving 15–25% long-term.

3.1 Assess Project Requirements

Match to applications (reservoirs: 1.5 mm HDPE $1.00–$2.00/sq ft; canals: 0.75 mm PVC $0.60–$1.50/sq ft; embankment: textured LLDPE $0.70–$1.80/sq ft). Evaluate head (50 m+), pH, UV.

3.2 Prioritize Quality

Virgin resin, GRI-GM13 certified (BPM); avoid recycled for critical, cut failures 20%.

3.3 Evaluate Installation Needs

Weldable for HDPE (15% faster); certified crews reduce 10–20% lifespan loss (BPM Geomembrane).

3.4 Consider Long-Term Costs

Thicker/quality save 20–30% over 50 years (1.5 mm HDPE vs. 0.75 mm PVC).

3.5 Compare Suppliers

Quote for quality/support (BPM custom; Solmax LLDPE). Bulk from BPM saves 10–20%.

4. Industry Trends Affecting Dam Lining Costs

- Raw Fluctuations: Oil up 10–20%, HDPE 5–8%.

- Wider Rolls: 8 m (Atarfil) cuts installation 15%.

- Smart Liners: Sensors (BPM) +5–10%, -20% maintenance.

- Sustainability: Recyclable $0.50–$3.00/sq ft, +10% production.

- Global: Asia $0.28–$2.00/sq ft vs. West higher.

5. Conclusion

Dam lining prices in 2025 range $0.50–$3.00/sq ft, with HDPE $0.50–$2.50/sq ft for large, LLDPE $0.60–$2.40/sq ft for canals. Installation 25–60%; prioritize virgin (BPM/Solmax) for performance. Contact BPM Geosynthetics for quotes/samples for leak-proof dams.