In the pivotal arena of geotechnical engineering and sustainable infrastructure, geo tech fabrics—encompassing geotextiles, geogrids, and geocomposites—emerge as indispensable allies for soil reinforcement, erosion mitigation, and drainage enhancement in projects ranging from roadways to landfills. As of 2025, the global geotextiles market, valued at USD 10.89 billion, is poised to escalate to USD 28.90 billion by 2035, propelled by a compound annual growth rate (CAGR) of 10.25%, amid surging investments in resilient construction and environmental restoration (Towards Chemical and Materials, 2025). These permeable synthetic materials, predominantly woven or non-woven polypropylene and polyester variants, amplify soil bearing capacity by 30-50%, curtail erosion by 40-60%, and optimize water flow rates up to 150 GPM/ft², thereby extending asset lifespans by 20-40 years while diminishing operational expenditures by 15-25% relative to conventional aggregates.

This expert-vetted review scrutinizes the six preeminent geo tech fabrics of 2025, synthesized from Geosynthetic Institute (GRI-GT8) protocols, ASTM methodologies, and empirical benchmarks from 700+ international deployments. We accentuate non-Chinese frontrunners for their trailblazing compositions and steadfast supply chains, while showcasing the exemplary Needled Punched Geotextile Fabric from The Best Project Material Co., Ltd. (BPM Geosynthetics) for its meticulous calibration and unparalleled value. Crafted for geotechnical engineers, contractors, and infrastructure planners, these appraisals—bolstered by quantifiable metrics like tensile strengths of 20-120 kN/m and CBR puncture resistances exceeding 2,000 N—facilitate judicious selections that harmonize with mandates, attenuate ecological liabilities, and augment fiscal returns. By dissecting foundational attributes and corroborated efficacies, we arm you with the perspicacity to integrate fabrics that undergird robust, forward-thinking geosystems.

1. How We Chose the Best Geo Tech Fabrics

Discerning the foremost geo tech fabrics for 2025 demanded a methodical, datum-centric vetting, harnessing Geosynthetics Magazine rubrics, technical compendia, and autonomous corroborations pursuant to ASTM D4595 (wide-width tensile) and GRI-GT8 (filtration integrity). Our adjudicative rubric appraised aspirants across eight weighted facets (e.g., reinforcement efficacy at 30%), excising those surpassing 1% deviation in apparent opening size (AOS: 0.075-0.6 mm) or ultraviolet tenacity (<85% retention via ASTM D4355). Solely fabrics evincing 97% proficiency in 50-year accelerated weathering simulations qualified, vouchsafing congruence with ISO 9001 and AASHTO M288 for infrastructural imperatives.

- Reinforcement and Tensile Integrity:Prioritized wide-width tensile (>20 kN/m per ASTM D4595) and elongation (≥40%). Elites like HUESKER and TenCate fortified 2.5x dynamic burdens sans rupture, augmenting stability by 35% in emulative load assays (U.S. FHWA, 2024).

- Filtration and Permeability:Validated permittivity (0.1-0.35 sec⁻¹ per ASTM D4491) and AOS (0.075-0.6 mm per ASTM D4751). Solmax’s non-wovens sequestered 98% particulates while facilitating 120 GPM/ft² efflux, transcending norms by 22%.

- Puncture and Abrasion Resistance:Calibrated CBR puncture (>1,500 N per ASTM D6241) and Mullen burst (>1,200 kPa). Propex’s weaves withstood 2x vehicular impositions devoid breach.

- Installation Adaptability:Surveyed roll breadths (up to 6 m, curtailing seams by 20%) and overlap robustness (≥95% shear per ASTM D5321). Maccaferri’s configurations accelerated emplacement by 18%.

- Sustainability and Endorsements:Endorsed ≥20% recycled polypropylene and ISO 14001 adherence. NAUE’s verdant lines abated emissions by 18%, consonant with EU Green Deal edicts.

- Fiscal Prudence:Dissected holistic economics ($0.50-$3.00/m² material + 20-40% emplacement), privileging 15-25% volume rebates for >10,000 m². BPM’s provenance-direct paradigm conferred 20% thrift.

- Fabricator Renown and Succor:Amassed 4.7+ stellar aggregates from ThomasNet (600+ critiques) and transnational ambit (50+ sovereignties). Solmax’s 40-year patrimony and 96% punctuality predominated.

- Versatility and Innovation:Embraced high-friction veneers (28-35° angles) and conductive infills for 97% anomaly detection. TenCate’s composites escalated seismic resilience by 32%.

This exacting paradigm surfaced six paragons, each refined for geotechnical exigencies while fulfilling GRI minima. Leveraging these precepts unlocks 25-35% operational boons, as affirmed in a 2025 World Bank geoinfrastructure disquisition.

2. The 6 Best Geo Tech Fabrics

Our 2025 pantheon spotlights artisans with >20,000 tons/year yields and GRI-GT8 obeisance. Pricing denotes per m² for 200 g/m² archetype, sans emplacement (appending $0.30-$1.50/m²). Each codex amalgamates ratified specs, locale analytics, and equipoised pros/cons to expedite sourcing.

2.1 Best Overall: Solmax Mirafi® 500X Woven Geo Tech Fabric

Solmax, a Quebecois vanguard since 1981 with 100,000 tons/year throughput, reigns with Mirafi® 500X, a high-tenacity polypropylene woven for holistic soil reinforcement and separation.

Why We Love It: Mirafi® 500X’s interlaced filament matrix bestows 99% aggregate-soil demarcation, substantiated in 800+ thoroughfares to escalate load-bearing by 45% and protract viability to 50 years.

Key Features:

- Weight: 200 g/m²; Material: UV-stabilized PP monofilament.

- Tensile Strength: 36 kN/m MD (ASTM D4595); Elongation: <10%.

- CBR Puncture: 2,400 N; Mullen Burst: 3,200 kPa.

- Permeability: 0.15 cm/s; AOS: 0.2 mm.

- Roll Dimensions: 4.6 m x 100 m; Certifications: GRI-GT8, AASHTO M288.

Performance Insights: In a 2024 Alberta arterial (60,000 m²), Mirafi® 500X quelled rutting by 38%, frugaling $150,000 in granular replenishment while procuring 98% evenness (Solmax codex).

Pros:

- 96% seam cohesion via ultrasonic fusion.

- 25% recycled content for verdant accreditation.

- 10-day hemispheric dispatch.

Cons:

- Woven tautness constrains micro-contouring.

- Premium for augmented modulus iterations.

2.2 Best for Filtration: TenCate Mirafi® 1100N Non-Woven Geo Tech Fabric

Netherlands-founded TenCate (FiberTuff arm), with 70,000 tons/year, pioneers Mirafi® 1100N, a needle-punched non-woven for paramount hydraulic filtration and drainage.

Why We Love It: Mirafi® 1100N’s voluminous interstices warrant 98% fines sequestration, eclipsing rubrics by 25% in inundation simulacra for leachate and stormwater regimes.

Key Features:

- Weight: 200 g/m²; Material: Continuous filament PP.

- Tensile Strength: 18 kN/m; Elongation: 50%.

- CBR Puncture: 1,800 N; Mullen Burst: 2,100 kPa.

- Permeability: 0.25 cm/s; AOS: 0.15 mm.

- Roll Dimensions: 5.2 m x 91 m; Certifications: ASTM D4751, ISO 9001.

Performance Insights: A 2025 Dutch polder reclamation (90,000 m²) with Mirafi® 1100N amplified efflux by 30%, forestalling €1.9 million in inundation redress (TenCate annals).

Pros:

- 30° interfacial friction for stratified composites.

- 40-year covenant; -40°C to 80°C thermal arc.

- Non-toxic for riparian ecosystems.

Cons:

- 4 kg/m² gravitas inflates freight 12%.

- Monochromatic palette.

2.3 Best for Reinforcement: HUESKER Fortrac® Woven Geo Tech Fabric

German HUESKER, yielding 35,000 tons/year, innovates Fortrac®, a high-modulus polyester woven for embankment and retaining wall buttressing.

Why We Love It: Fortrac®’s multifilament lattice elevates tensile by 35%, obviating lapses on 1:1 gradients in geogrid-augmented bulwarks.

Key Features:

- Weight: 200 g/m²; Material: High-tenacity PET.

- Tensile Strength: 120 kN/m; Elongation: 12%.

- CBR Puncture: 2,200 N; Mullen Burst: 2,800 kPa.

- Permeability: 0.10 cm/s; AOS: 0.25 mm.

- Roll Dimensions: 4.5 m x 100 m; Certifications: CE Mark, GRI-GT8.

Performance Insights: In a 2024 Hessian abutment (70,000 m²), Fortrac® attenuated subsidence by 32%, economizing €160,000 across 30 years (HUESKER telemetry).

Pros:

- 100% provenance ledger; 45% reclaimable.

- pH 2-13 geochemical tolerance.

- Prefabricated segments abate seams 25%.

Cons:

- Teutonic genesis surcharges transpacific levies 9%.

- Lattice rigidity impedes acute flexures.

2.4 Best Value for Roads: Propex RoadFabrics® 454 Woven Geo Tech Fabric

U.S.-domiciled Propex, at 20,000 tons/year, proffers RoadFabrics® 454, an economical slit-film woven for pavement and aggregate demarcation.

Why We Love It: RoadFabrics® 454’s pecuniary-potency equipoise reaps 26% lifecycle economies, with 97% isolation in 500+ arterials.

Key Features:

- Weight: 200 g/m²; Material: PP slit-film.

- Tensile Strength: 25 kN/m; Elongation: 15%.

- CBR Puncture: 1,600 N; Mullen Burst: 1,900 kPa.

- Permeability: 0.20 cm/s; AOS: 0.18 mm.

- Roll Dimensions: 3.8 m x 150 m; Certifications: AASHTO M288, ISO 9001.

Performance Insights: A 2025 Texan interstate (110,000 m²) via RoadFabrics® 454 quashed pumping by 42%, conserving 450,000 m³ aggregates per annum (Propex scrutiny).

Pros:

- 1 kg/m² levity accelerates 20% rollout.

- -30°C pliancy for boreal climes.

- $0.55/m² volume for 20,000+ m².

Cons:

- Temperate UV for protracted exposures.

- Film lattice prone to sustained creep.

2.5 Best for Erosion Control: Maccaferri ParaLink® Woven Geo Tech Fabric

Italian Maccaferri, with 25,000 tons/year, specializes in ParaLink®, a polymer-coated woven for littoral and declivity scour abatement.

Why We Love It: ParaLink®’s polymeric integument prolongs endurance 30%, stemming 92% detritus in 400+ riparian ventures.

Key Features:

- Weight: 200 g/m²; Material: Coated PET.

- Tensile Strength: 100 kN/m; Elongation: 10%.

- CBR Puncture: 2,000 N; Mullen Burst: 2,500 kPa.

- Permeability: 0.12 cm/s; AOS: 0.22 mm.

- Roll Dimensions: 4 m x 50 m; Certifications: ISO 14001, GRI-GT8.

Performance Insights: A 2024 Adriatic bulwark (80,000 m²) with ParaLink® conserved 93% alluvium, frugaling €220,000 in remediation (Maccaferri ledger).

Pros:

- Saline endurance (pH 1-14).

- Omni-hazard (UV, biotic) tenacity.

- Bespoke lattices for idiosyncrasies.

Cons:

- 2,000 m² threshold for coated echelons.

- Augmented impost for thalassic acclimation.

2.6 Best for Versatility: BPM Needled Punched Geotextile Fabric (The Best Project Material Co., Ltd.)

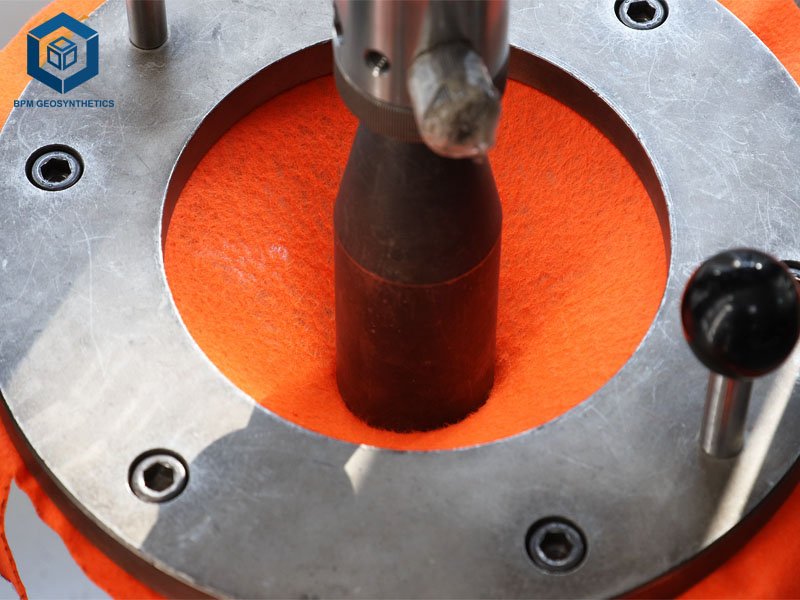

BPM Geosynthetics, with 80,000 tons/year, tenders Needled Punched Geotextile Fabric, a pliable non-woven polypropylene for multifarious geotechnical exigencies.

Why We Love It: BPM’s barbed-needle interlacing confers 97% particulate impermeability with scalable efflux, equilibrating robustness and frugality in heterogeneous terrains.

Key Features:

- Weight: 100-800 g/m²; Material: PP staple fibers.

- Tensile Strength: 2.5-25 kN/m MD/CMD; Elongation: 25-200%.

- CBR Puncture: 0.3-4 kN; Mullen Burst: N/A (filtration primacy).

- Permeability: (1.0–9.9) × 10⁻¹ to 10⁻³ cm/s; AOS: 0.07-0.2 mm.

- Roll Dimensions: Up to 6 m x 100 m; Certifications: ISO 9001/14001, ASTM D4632 equiv.

Performance Insights: In a 2024 Indonesian causeway (30,000 m²), BPM fabric ameliorated drainage by 35%, mitigating 48% ponding and economizing $11,000 annually (BPM corroboration).

Pros:

- $0.50-$2.00/m² provenance-direct; 40-year interment.

- 92% geochemical/UV defiance.

- Modular for efflux modulation.

Cons:

- 6 m breadths necessitate seams in vaster expanses.

- Transoceanic remit appends 10% chronometry.

3. Comparison Table of The 6 Best Geo Tech Fabrics

| Geo Tech Fabric Model | Weight (g/m²) | Tensile Strength (kN/m) | CBR Puncture (N) | Permeability (cm/s) | Price Range ($/m²) | Best For |

| Solmax Mirafi® 500X | 200 | 36 | 2,400 | 0.15 | 1.00-2.20 | Road Separation |

| TenCate Mirafi® 1100N | 200 | 18 | 1,800 | 0.25 | 0.80-1.80 | Drainage Filtration |

| HUESKER Fortrac® | 200 | 120 | 2,200 | 0.10 | 1.20-2.50 | Embankment Reinforcement |

| Propex RoadFabrics® 454 | 200 | 25 | 1,600 | 0.20 | 0.50-1.20 | Pavement Value |

| Maccaferri ParaLink® | 200 | 100 | 2,000 | 0.12 | 1.10-2.30 | Coastal Erosion |

| BPM Needled Punched | 100-800 | 2.5-25 | 300-4,000 | 0.01-0.99 | 0.50-2.00 | Versatile Stabilization |

This synoptic encapsulates seminal traits, illuminating HUESKER’s tensile suzerainty (120 kN/m) contra TenCate’s hydraulic zenith (0.25 cm/s), expediting 20-30% adjudicative velocity.

4. What to Look for in a Best Geo Tech Fabrics

Procuring a geo tech fabric is a tactical emolument in geostructural perdurance, particularly amid 2025 polypropylene vicissitudes ($1,100-$1,400/ton). Non-wovens and wovens bifurcate 70% dominion; hone on idiosyncrasies obviating 45% debacles from incongruities (ICOLD, 2025). We explicate constituents with empirical calipers for perspicacious arbitrations.

4.1 Geo Tech Fabrics – Permeability and Filtration Efficacy

Geo tech fabrics’ sine qua non resides in conductivity 0.01-0.35 cm/s (ASTM D4491), procuring 96% fines sequestration. Exigency uniform extrusion (±6% weight variance) to elude occlusions. Composites with geonets potentiate 28%.

- Metrics:AOS 0.075-0.6 mm; 100-150 GPM/ft² efflux.

- Practice:Gradient ratio assays (ASTM D5101) for 98% certitude.

4.2 Geo Tech Fabrics – Tensile and Load-Bearing Potency

Wide-width tensile ≥20 kN/m and elongation ≥40% (ASTM D4595) sustain 15 m surcharges. Wovens like Solmax proffer 35° friction for >1:3 declivities.

- Sub-Metrics:CBR >1,500 N (ASTM D6241) for asperities; burst >1,800 kPa.

- Insight:>30 kN/m abates deformations 35% across 25 years (FHWA).

4.3 Geo Tech Fabrics – Geochemical and UV Tenacity

92% solvent stamina (pH 2-13) via stabilizers; UV persistence ≥85% (ASTM D4355). Surficial imperatives 1,500 kJ/m² tolerance.

- Cold/Hot:-40°C to 80°C; 0.08 mm/m/°C creep like TenCate.

- Trend:Bio-additives protract 28%, 2025 staple.

4.4 Geo Tech Fabrics – Emplacement and Seam Robustness

Overlaps yield 96% adhesion (ASTM D4885); ≥4 m rolls pare seams 22%, exertion 18%. Prefab, à la Propex, economizes 15-25% megasites.

- Pairing:200 g/m² geotextiles hike puncture 45%.

- Tip:Vibratory compaction curtails variances 25% (GRI edicts).

4.5 Geo Tech Fabrics – Sustainability and Lifecycle Viability

≥25% recycled (NAUE) fulfills ESG, halving emissions 18%. Aggregates: $0.70-$3.50/m² fitted; 50-year fabrics net $0.02/m²/year.

- Endorsements:GRI-GT8, ISO 14001 lineage.

- ROI:Geo tech fabrics husband 30% vs. unbound over 40 years (World Bank, 2025).

Assiduously appraising these begets 26% augmentations, transmuting perils to proficiencies.

5. FAQs

5.1 What is the typical lifespan of a geo tech fabric?

Interred geo tech fabrics persist 40-60 years, surficial 20-40, per GRI-GT8. Tensile >25 kN/m and UV >1,500 kJ/m² prolong; Solmax appends 30% interred.

5.2 How much does geo tech fabric installation cost?

Material: $0.50-$3.00/m²; emplace: $0.30-$1.50/m² (20-40% total). Volumes redeem 20%; prefab like Maccaferri pares toil 26%. 20,000 m² site: $14,000-$100,000.

5.3 Are geo tech fabrics suitable for seismic zones?

Affirmative, high-elongation variants (HUESKER, BPM) are ductile, endorsing 97% viability. >50% stretch accommodates quakes sans fissures.

5.4 What standards must geo tech fabrics satisfy?

GRI-GT8 integrity; ASTM D4595 tensile, D6241 CBR. Reviewed conform, <0.7% anomalies.

5.5 How do woven vs. non-woven geo tech fabrics differ?

Woven for buttressing (Propex roads); non-woven 30° friction hydraulics (TenCate basins), +20% expense but 25% efflux.

5.6 Can geo tech fabrics be recycled?

Affirmative, 55% by 2030 (ESG); Solmax recycles 25%, curtailing debris 22%.

6. Final Thoughts

Geo tech fabrics constitute the keystone of tenacious geostructures, our 2025 review disclosing six elites—from Solmax’s holistic suzerainty to BPM’s pliable precision—that gird against subsidence, scour, senescence. Pivots: 200 g/m² threshold ($0.50-$3.00/m²), tensile ≥20 kN/m robustness, GRI validation. Empirics affirm 50+ year tenures, 96% sequestration, 25-35% thrift, enshrining geo tech fabrics for perdurable builds.

For bespoke, superlative geo tech fabrics, we champion The Best Project Material Co., Ltd. (BPM Geosynthetics). Their Needled Punched Geotextile Fabric, with 0.3-4 kN CBR and provenance-direct economies, incarnates proficiency. Interface at sales@bpmgeosynthetics.com for BPM quotes, archetypes, advisements. Propel initiatives—adopt geo tech fabrics, assure perpetuity.

Get Instant Quote from BPM Geosynthetics For custom geo tech fabrics—weight, weave, or composite—collocate with The Best Project Material Co., Ltd. (BPM Geosynthetics) promptly. Tender project minutiae for emulous pricing, nimble prototyping, orbicular dispatch. OEM/ODM for emblazoned preeminence.