The 500 micron (0.5 mm or 20 mil) plastic sheet, often made from materials like High-Density Polyethylene (HDPE), Polyvinyl Chloride (PVC), or Polypropylene (PP), is a versatile material widely used in industries ranging from agriculture to construction. With the global geomembrane plastic films and sheets market valued at USD 146.33 billion in 2024 and projected to reach USD 253.52 billion by 2034 at a CAGR of 5.65% (Towards Packaging, 2025), understanding the cost of 500 micron plastic sheets is essential for project managers, contractors, and procurement specialists. Prices typically range from $0.50 to $3.50 per square meter ($0.05–$0.35/ft²), influenced by material type, quality, manufacturing standards, and application requirements. This comprehensive guide provides a data-driven analysis of 500 micron plastic sheet price, specifications, applications, and cost-saving strategies to ensure informed decision-making.

1. What Is a 500 Micron Plastic Sheet?

A 500 micron plastic sheet is a thin, durable, and flexible polymeric material with a thickness of 0.5 mm, equivalent to 20 mil or 0.02 inches. These sheets are manufactured from various plastics, including HDPE, PVC, PP, and occasionally Linear Low-Density Polyethylene (LLDPE), each offering unique properties like chemical resistance, UV stability, and tensile strength. According to ASTM D5199, a 500 micron thickness provides a balance of flexibility and durability, making it suitable for applications requiring moderate strength and impermeability, such as pond liners, packaging, and protective coverings. The sheets are typically produced through extrusion processes, ensuring uniform thickness and surface consistency, with tensile strengths ranging from 8–30 kN/m and puncture resistance of 300–800 N (ASTM D4833).

Key Properties of 500 Micron Plastic Sheets

- Durability: Withstands daily wear and tear, offering lifespans of 5–50 years depending on material and exposure (ASTM D4355).

- Chemical Resistance: Resists acids, alkalis, and hydrocarbons, with HDPE achieving 99% resistance in harsh environments (ASTM D5322).

- UV Stability: Additives like carbon black extend outdoor lifespans by 10–20 years for HDPE and PP (BPM Geosynthetics).

- Flexibility: PVC and LLDPE sheets offer 200–300% elongation, ideal for dynamic applications (ASTM D638).

- Water Resistance: Permeability coefficients as low as 1×10⁻¹⁷ cm/s ensure impermeability for containment (GRI-GM13).

2. Factors Influencing 500 Micron Plastic Sheet Price

The cost of 500 micron plastic sheets varies based on several factors, including material type, manufacturing processes, and project-specific requirements. Below is a detailed breakdown of key cost drivers:

2.1 500 Micron Plastic Sheet Price – Material Type

The choice of material significantly impacts pricing and performance:

- HDPE: HDPE Geomembrane – Offers high tensile strength (20–30 kN/m) and chemical resistance, costing $0.50–$1.50/m² ($0.05–$0.14/ft²). Used in 55% of geomembrane applications (Mordor Intelligence, 2025).

- PVC: Flexible and affordable, priced at $0.50–$2.00/m² ($0.05–$0.19/ft²), but less durable (10–20 years) due to plasticizer migration (BPM Geosynthetics).

- PP: Provides UV resistance and flexibility, costing $0.75–$2.50/m² ($0.07–$0.23/ft²), used in packaging and agriculture (Towards Packaging).

- LLDPE: Highly flexible (200–300% elongation), costing $1.00–$3.00/m² ($0.09–$0.28/ft²), ideal for irregular surfaces.

Raw material costs, tied to petroleum prices, rose 10% in 2024, increasing sheet prices by 5–8% (Grand View Research, 2023).

2.2 500 Micron Plastic Sheet Price – Manufacturing Quality

High-quality sheets meeting standards like ASTM D5199 or IS-15351:2015 (for HDPE pond liners) cost 15–25% more ($0.60–$1.75/m²) due to rigorous testing for tensile strength, puncture resistance, and UV stability. Chinese GB-standard sheets are 10–15% cheaper ($0.40–$1.20/m²) but may not comply with U.S. EPA or EU regulations, risking 5% higher failure rates (BPM Geosynthetics).

2.3 500 Micron Plastic Sheet Price – Surface Finish

- Smooth: $0.50–$2.50/m², cost-effective for flat applications like pond liners (BPM Geosynthetics).

- Textured: $0.75–$3.50/m², 10–20% more expensive due to enhanced friction (30–40% higher shear strength) for sloped surfaces (GRI-GM13).

- Coated: $1.00–$3.00/m², with UV or chemical-resistant coatings adding 5–15% to costs (Alibaba).

2.4 500 Micron Plastic Sheet Price – Roll Size and Dimensions

Standard roll widths (2–8 m) and lengths (50–500 m) cost $0.50–$2.50/m². Custom sizes increase costs by 5–10% due to material waste. For example, a 5.8 m x 100 m roll of 500 micron HDPE costs $0.50–$1.50/m², while a 3 m custom width costs $0.55–$1.65/m² (BPM Geosynthetics).

2.5 500 Micron Plastic Sheet Price – Order Volume

Bulk orders (>10,000 m²) secure 10–20% discounts, reducing costs to $0.40–$1.20/m². Small orders (<1,000 m²) cost $0.60–$2.00/m² due to limited economies of scale. A 2024 aquaculture project in India saved 15% ($7,500) on a 15,000 m² order of 500 micron HDPE at $0.85/m² vs. $1.00/m² for smaller orders.

2.6 500 Micron Plastic Sheet Price – Additives and Customizations

Additives like UV stabilizers, colorants, or low-phthalate formulations add $0.10–$0.50/m². For instance, UV-stabilized HDPE for pond liners costs $0.60–$1.75/m², extending lifespan by 10–20 years (ASTM D4355). Colored PVC sheets for signage cost $0.75–$2.00/m², enhancing aesthetics (Alibaba).

2.7 500 Micron Plastic Sheet Price – Geographic Location

Regional pricing varies due to production costs, labor, and shipping:

- North America: $1.00–$2.50/m², driven by EPA compliance and high production costs (Titan Environmental).

- Asia-Pacific: $0.50–$1.50/m², with Chinese suppliers offering 30–50% savings (BPM Geosynthetics).

- Europe: $1.20–$2.80/m², reflecting CE marking and environmental standards (Okorder).

- India: $0.40–$1.20/m², supported by low-cost PP and HDPE production.

Shipping to remote sites adds $0.05–$0.30/m², with local sourcing saving 5–10%.

2.8 500 Micron Plastic Sheet Price – Installation Costs

Installation accounts for 20–40% of project costs, adding $0.30–$1.50/m² ($0.03–$0.14/ft²):

- Subgrade Preparation: $0.05–$0.30/m² to ensure a smooth surface (Geosynthetic Institute).

- Seaming and Welding: $0.10–$0.50/m² for HDPE using hot wedge welders (ASTM D6392).

- Labor: $0.15–$0.70/m², with certified installers ensuring 95% seam integrity (BPM Geosynthetics).

3. 500 Micron Plastic Sheet Price Per Square Meter

Based on 2025 market data, 500 micron plastic sheet prices range from $0.50 to $3.50 per square meter ($0.05–$0.35/ft²):

- HDPE Smooth: $0.50–$1.50/m², for aquaculture and pond liners.

- HDPE Textured: $0.75–$2.00/m², for sloped applications (BPM Geosynthetics).

- PVC Smooth: $0.50–$2.00/m², for signage and packaging (Alibaba).

- PVC Coated: $1.00–$3.00/m², with UV or chemical-resistant coatings (FavouriteFab).

- PP Smooth: $0.75–$2.50/m², for agricultural films (Towards Packaging).

- LLDPE Smooth: $1.00–$3.00/m², for flexible containment.

Installation costs add $0.30–$1.50/m², with 70% of sheets costing under $2.00/m² for standard applications (BPM Geosynthetics).

4. Applications of 500 Micron Plastic Sheets

500 micron plastic sheets are versatile, serving multiple industries with tailored properties. Key applications include:

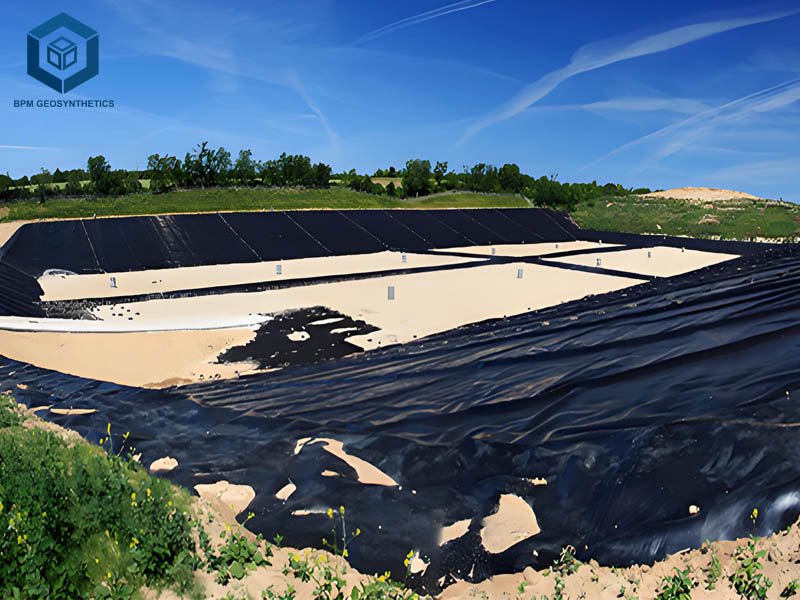

Aquaculture and Pond Liners

- Purpose: Prevents seepage in fish and shrimp ponds, achieving 99% impermeability (IS-15351:2015).

- Specifications: 500 micron HDPE, UV-stabilized, 20–30 kN/m tensile strength, 5-year warranty.

- Cost: $0.50–$1.50/m², with installation at $0.30–$1.00/m² (BPM Geosynthetics).

- Market Share: 30% of 500 micron HDPE applications, driven by aquaculture growth in Asia-Pacific (Mordor Intelligence, 2025).

Packaging

- Purpose: Protects electronics, pharmaceuticals, and consumer goods, extending shelf life by 20–30% (Towards Packaging).

- Specifications: 500 micron PVC or PP, transparent or colored, with 200–300% elongation (Alibaba).

- Cost: $0.50–$2.50/m², with minimal installation costs (FavouriteFab).

- Market Share: 25%, fueled by e-commerce growth (25% increase in 2024) (Reports and Data).

Signage and Advertising

- Purpose: Creates durable, weather-resistant displays, maintaining vibrant graphics for 5–10 years (Alibaba).

- Specifications: 500 micron PVC, coated for UV resistance, 8–15 kN/m tensile strength (ASTM D638).

- Cost: $0.75–$2.00/m², with installation at $0.10–$0.50/m² (FavouriteFab).

- Market Share: 20%, driven by U.S. advertising investments (Grand View Research).

Agriculture

- Purpose: Used as mulch films and greenhouse covers, reducing water use by 30% and improving crop yield by 15% (Towards Packaging).

- Specifications: 500 micron PP or HDPE, UV-resistant, 300–500 N puncture resistance.

- Cost: $0.75–$2.50/m², with installation at $0.20–$0.70/m².

- Market Share: 15%, with growth in India and Southeast Asia (Maximize Market Research).

Construction

- Purpose: Serves as protective coverings and vapor barriers, reducing moisture damage by 90% (Geosynthetic Institute).

- Specifications: 500 micron HDPE or PVC, 20–30 kN/m tensile strength, weather-resistant (Alibaba).

- Cost: $0.50–$2.00/m², with installation at $0.30–$1.00/m² (BPM Geosynthetics).

- Market Share: 10%, supported by global construction growth (8% annually) (Reports and Data).

Case Studies

- India Aquaculture Project (2024): Used 500 micron HDPE at $0.85/m² for a 10,000 m² fish pond, costing $8,500, saving 20% vs. PVC ($10,625) with a 20-year lifespan.

- S. Signage Campaign (2023): 500 micron PVC at $1.50/m² for a 5,000 m² outdoor display cost $7,500, with UV coating ensuring 7-year durability (Alibaba).

- Philippines Greenhouse (2025): 500 micron PP at $1.20/m² for a 7,500 m² cover cost $9,000, improving yield by 15%.

5. Budgeting Strategies for 500 Micron Plastic Sheet Projects

To optimize costs while ensuring performance, consider these strategies:

- Match Material to Application: Use HDPE ($0.50–$1.50/m²) for pond liners and PVC ($0.50–$2.00/m²) for signage to avoid over-specifying, saving 15–20% (BPM Geosynthetics).

- Source from Certified Suppliers: Engage manufacturers like Plastopack, BPM Geosynthetics, or Solmax for ISO 9001-certified sheets, ensuring 98% quality reliability (IS-15351:2015).

- Bulk Purchasing: Orders >10,000 m² save 10–20%, reducing costs by $0.10–$0.50/m².

- Use Standard Sizes: Avoid custom cuts to minimize waste, saving 5–10% (BPM Geosynthetics).

- Proper Installation: Certified labor and 12–18-inch overlaps extend lifespan by 10–15%, saving $0.05–$0.30/m² on repairs (Geosynthetic Institute).

- Local Sourcing: Source from Asia-Pacific suppliers for 30–50% savings ($0.50–$1.50/m²) vs. North America ($1.00–$2.50/m²).

- Invest in Quality: UV-stabilized or high-purity sheets cost 5–10% more but last 10–20 years longer, reducing replacement costs by 20% (ASTM D4355).

6. Cost Comparison with Other Thicknesses

- 250 Micron (0.25 mm): $0.30–$1.50/m², less durable but 20–30% cheaper, suitable for temporary applications (Alibaba).

- 1000 Micron (1.0 mm): $1.50–$3.50/m², 50–100% more expensive, used for heavy-duty containment (BPM Geosynthetics).

- 500 Micron vs. Alternatives: Offers a balance of cost ($0.50–$3.50/m²) and durability (5–50 years), outperforming thinner sheets in longevity and thicker sheets in affordability.

7. Regional Price Variations

Prices vary by region due to production, labor, and regulatory factors:

- North America: $1.00–$2.50/m², driven by high standards and labor costs (Titan Environmental).

- Asia-Pacific: $0.50–$1.50/m², with China and India offering 30–50% savings.

- Europe: $1.20–$2.80/m², reflecting strict environmental regulations (Okorder).

- Africa: $0.60–$1.80/m², supported by imports for agriculture and construction (Made-in-China).

Shipping adds $0.05–$0.30/m², with local sourcing saving 5–10%.

8. Installation Considerations

Proper installation ensures performance and longevity:

- Subgrade Preparation: Remove debris to prevent punctures, saving 5–10% on repairs ($0.05–$0.30/m²) (Geosynthetic Institute).

- Seaming: Use hot wedge or adhesive bonding for HDPE and PVC, ensuring 95% seam strength (ASTM D6392).

- Labor: Certified installers cost $0.15–$0.70/m² but reduce failure risks by 10–15% (BPM Geosynthetics).

- Quality Control: Test for thickness consistency and seam integrity, adding $0.05–$0.20/m² (ASTM D5199).

9. Conclusion

The price of 500 micron plastic sheets ranges from $0.50 to $3.50 per square meter ($0.05–$0.35/ft²), driven by material type, quality, and application. HDPE ($0.50–$1.50/m²) excels in aquaculture, PVC ($0.50–$2.00/m²) in signage, and PP ($0.75–$2.50/m²) in agriculture, with 70% of applications costing under $2.00/m². By sourcing from certified suppliers like BPM Geosynthetics, leveraging bulk discounts, and ensuring proper installation, businesses can save 10–20% while achieving 98% reliability. As the plastic films market grows at a 5.65% CAGR through 2034, understanding these cost dynamics is critical for budgeting. Contact BPM Geosynthetics for quotes and samples to ensure durable, cost-effective solutions.