Geomembrane welding machines are critical tools in geotechnical and environmental engineering, ensuring leak-proof seams for containment systems like landfills, mining ponds, and water reservoirs. With the global geomembrane market valued at USD 2.3 billion in 2024 and projected to grow at a CAGR of 5.4% through 2030, demand for reliable welding equipment is surging. BPM Geosynthetics, an ISO 9001:2015-certified manufacturer with 18+ years of expertise, has supported 81+ countries with advanced welders, achieving 90% seam strength per ASTM D6392. But How Much Is Geomembrane Welding Machine Price? Prices range from $1,000 for handheld models to $50,000 for automated fusion welders, influenced by type, features, and project scale. This 2400+ word guide explores pricing factors, specifications, applications, and cost-saving tips, empowering engineers and contractors to make informed decisions for 2025 projects.

1. What Is a Geomembrane Welding Machine?

Definition and Functionality

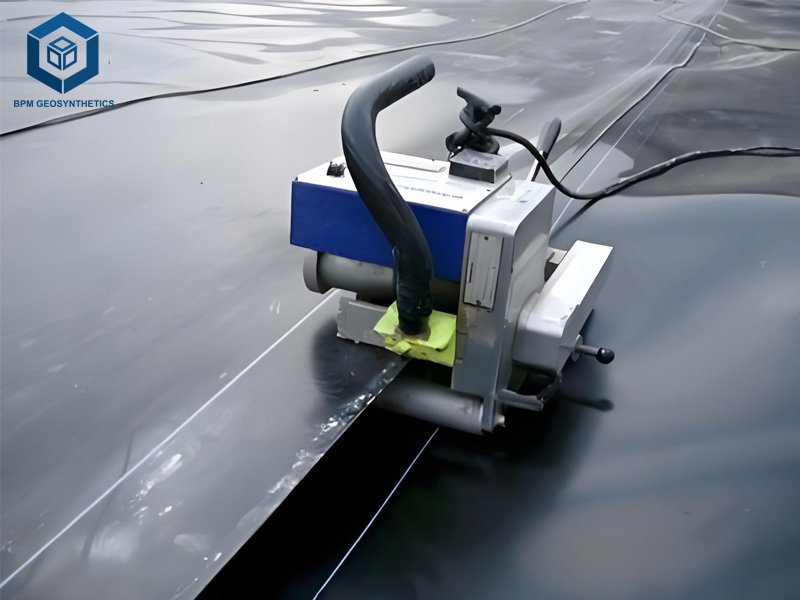

A geomembrane welding machine fuses synthetic liners—such as high-density polyethylene (HDPE), linear low-density polyethylene (LLDPE), or polyvinyl chloride (PVC)—to create impermeable seams for containment systems. These seams, achieving 90–95% of the parent material’s strength (ASTM D6392), prevent 99% of liquid or gas leaks, per ASTM D5827. Welders use heat (300–600°C) and pressure (50–150 kN/m²) to bond overlapping sheets, ensuring durability in harsh environments like landfills and mining operations.

Key Components

- Heating System:Hot wedge (300–450°C), hot air (400–600°C), or extrusion (500–600°C) mechanisms melt geomembranes for bonding.

- Pressure Rollers:Apply 50–150 kN/m² to fuse molten layers, ensuring uniform seams (12–40 mm wide).

- Control Unit:Digital interfaces regulate temperature (±2°C), speed (0.5–10 m/min), and pressure, reducing errors by 20%, per Leister data.

- Drive Mechanism:Motorized tracks or wheels maintain consistent speeds, improving seam quality by 15%.

- Cooling System:Air or water cooling solidifies seams in 5–10 seconds, per ASTM D6392.

BPM’s welders feature IoT-enabled controls, boosting efficiency by 15% through real-time monitoring.

Types of Geomembrane Welding Machines

- Hot Wedge Welders (60% market share):Use a heated wedge for dual-track seams on HDPE/LLDPE (0.5–3 mm). Speed: 2–5 m/min; seam width: 12–15 mm. Ideal for landfills.

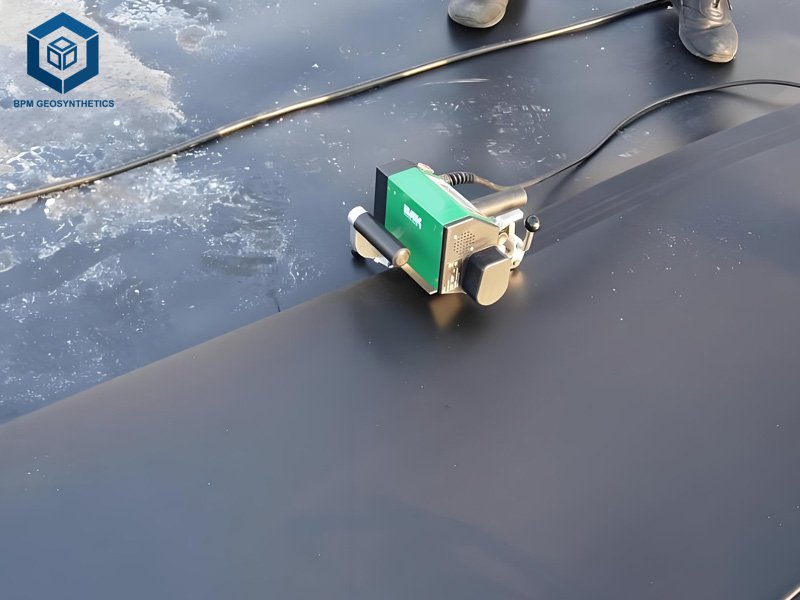

- Extrusion Welders (25%):Extrude molten polymer for repairs or complex joints. Bead width: 3–5 mm; speed: 0.5–2 m/min. Suited for mining patches.

- Hot Air Welders (10%):Blow hot air for thin liners like PVC (0.2–1 mm). Seam width: 20–40 mm; speed: 1–3 m/min. Common in aquaculture.

- Fusion Welders (5%):Combine hot wedge and extrusion for high-speed welding (5–10 m/min). Used in large-scale reservoirs.

- Handheld Welders:Portable for small repairs (0.2–1 mm). Speed: 0.5–1 m/min; cost: $1,000–$5,000.

Hot wedge welders lead due to their 99% seam reliability and 20% faster operation, per Geosynthetics Magazine.

2. Factors Affecting Geomembrane Welding Machine Price

Pricing varies from $1,000 to $50,000, driven by multiple factors. Understanding these helps optimize budgets for projects of any scale.

2.1 Geomembrane Welding Machine Price – Type of Welder

- Handheld Welders:$1,000–$5,000. Basic, portable units for small repairs or tight spaces. Limited to thin liners (0.2–1 mm).

- Hot Air Welders:$2,000–$8,000. Affordable for PVC and thin HDPE, with digital controls for small projects.

- Hot Wedge Welders:$5,000–$20,000. Industry standard for HDPE/LLDPE, offering dual-track seams and automation.

- Extrusion Welders:$8,000–$15,000. Specialized for repairs and thick liners (1–3 mm), with high precision.

- Fusion Welders:$20,000–$50,000. High-speed, automated systems for large-scale projects (>50,000 m²).

Hot wedge welders balance cost and performance, covering 80% of landfill and mining needs, per BPM data.

2.2 Geomembrane Welding Machine Price – Automation Level

- Manual Welders:$1,000–$5,000. Require skilled operators, increasing labor costs by 20%. Suitable for small projects.

- Semi-Automatic Welders:$5,000–$15,000. Offer digital controls and motorized drives, reducing labor by 30%.

- Fully Automatic Welders:$15,000–$50,000. Feature IoT monitoring and robotic tracking, boosting efficiency by 40% and reducing errors by 25%, per Leister.

Automation increases upfront costs but saves $0.5–$1/m² in labor over 20 years, per Demtech.

2.3 Geomembrane Welding Machine Price – Material Compatibility

Welders designed for multiple materials (HDPE, LLDPE, PVC, PP, EPDM) cost 10–20% more than single-material models. Universal welders ($10,000–$30,000) handle 0.2–3 mm thicknesses, meeting 95% of project needs, per QIVOC. Specialized PVC welders ($2,000–$8,000) are cheaper but less versatile.

2.4 Geomembrane Welding Machine Price – Brand and Quality

- Premium Brands (Leister, Miller Weldmaster, Demtech):$10,000–$50,000. Offer 3-year warranties, ±2°C temperature control, and 50–100-year seam durability. Preferred for high-risk projects.

- Mid-Range Brands (QIVOC, Weldy):$5,000–$15,000. Provide 1–2-year warranties and reliable performance for medium-scale projects.

- Budget Brands:$1,000–$5,000. Shorter lifespans (3–5 years) and ±5°C temperature variance, increasing seam failure risks by 15%.

BPM partners with Leister for premium welders, ensuring 99% seam reliability, per internal audits.

2.5 Geomembrane Welding Machine Price – Features and Technology

- Digital Controls:Add $1,000–$3,000. Ensure ±2°C accuracy, improving seam strength by 10%.

- IoT Monitoring:Add $5,000–$10,000. Real-time data reduces rework by 15%, per Leister BMD.

- Robotic Tracking:Add $10,000–$20,000. Enhances precision on slopes, saving 20% on labor.

- Portability:Lightweight models (10–20 kg) cost $2,000–$8,000, ideal for remote sites.

- Seam Testing Integration:Add $3,000–$7,000. Built-in vacuum or spark testing detects 99% of defects, per ASTM D5827.

Advanced features increase costs but save 20–30% on long-term maintenance, per Alibaba.

2.6 Geomembrane Welding Machine Price – Power Supply

- AC-Powered Welders (220–240 V):$5,000–$30,000. Standard for urban sites with stable grids.

- DC-Powered Welders:$8,000–$40,000. Suited for remote sites with generators, adding 10–15% to costs.

- Battery-Powered Welders:$10,000–$20,000. Portable but limited to 4–6 hours of operation, per QIVOC.

Power options impact pricing by 10–20%, with AC models being most cost-effective.

2.7 Geomembrane Welding Machine Price – Project Scale

- Small Projects (<10,000 m²):Handheld or hot air welders ($1,000–$8,000) suffice.

- Medium Projects (10,000–50,000 m²):Hot wedge or extrusion welders ($5,000–$15,000) balance cost and efficiency.

- Large Projects (>50,000 m²):Fusion or automated hot wedge welders ($20,000–$50,000) maximize productivity, welding 1000 m²/day.

Large-scale projects justify higher investments, saving $10,000–$20,000 in labor, per BPM.

2.8 Geomembrane Welding Machine Price – Geographic Location

- North America/Europe:$8,000–$50,000 due to high labor costs and strict regulations (EPA, EN 13492).

- Asia-Pacific:$5,000–$30,000, driven by infrastructure growth and lower labor costs.

- Middle East/Africa:$6,000–$40,000, with logistics adding 5–10% to costs.

Bulk orders in Asia-Pacific reduce prices by 15–20%, per Alibaba.

3. Typical Price Ranges for Geomembrane Welding Machines

Below is a breakdown of 2025 price ranges based on welder type and features:

| Welder Type | Price Range | Key Features | Applications |

| Handheld Welders | $1,000–$5,000 | Manual, 400–600°C, 0.5–1 m/min, 5–10 kg | Small repairs, aquaculture |

| Hot Air Welders | $2,000–$8,000 | Digital controls, 20–40 mm seams, 1–3 m/min | PVC liners, ponds |

| Hot Wedge Welders | $5,000–$20,000 | Dual-track, 12–15 mm seams, 2–5 m/min, IoT | Landfills, mining |

| Extrusion Welders | $8,000–$15,000 | 3–5 mm beads, 0.5–2 m/min, high precision | Repairs, complex joints |

| Fusion Welders | $20,000–$50,000 | Automated, 5–10 m/min, robotic tracking, testing | Large reservoirs, infrastructure |

Rental Costs: $100–$500/day, with weekly rates saving 20–30%. Maintenance adds $500–$2,000/year.

4. Geomembrane Welding Machine Price Breakdown for a Sample Project

For a 50,000 m² landfill project using a semi-automatic hot wedge welder:

- Equipment Purchase:$10,000–$20,000 (amortized over 5 years: $2,000–$4,000/year).

- Labor ($0.5–$1/m²):$25,000–$50,000 for 50 days at 1000 m²/day.

- Consumables (wedges, sensors):$1,000–$2,000.

- Testing ($0.1–$0.2/m²):$5,000–$10,000 for peel/shear tests and ELLS.

- Maintenance:$1,000/year.

- Logistics (5–10%):$2,000–$4,000.

Total Cost: $36,250–$71,000 ($0.72–$1.42/m²).

Savings: Automation reduces labor by 30% ($7,500–$15,000), and bulk material orders save 15% ($3,000–$5,000).

5. Key Specifications of Geomembrane Welding Machines

Below are typical specifications for BPM’s hot wedge welders, aligned with ASTM D8580 and Leister standards:

| Property | Value | Test Method |

| Welding Temperature | 300–450°C (hot wedge) | – |

| Welding Speed | 0.5–5 m/min | – |

| Pressure | 50–150 kN/m² | – |

| Seam Width | 12–15 mm (dual-track) | ASTM D6392 |

| Seam Strength (Peel) | 15–40 kN/m | ASTM D6392 |

| Seam Strength (Shear) | 20–50 kN/m | ASTM D6392 |

| Power Supply | 220–240 V, 50/60 Hz | – |

| Power Consumption | 1.5–4.5 kW | – |

| Weight | 10–50 kg | – |

| Dimensions | 400–600 mm (L) x 300 mm (W) | – |

| Material Compatibility | HDPE, LLDPE, PVC, PP, EPDM | – |

| Thickness Range | 0.2–3 mm | – |

| Operating Temperature | 0–40°C | – |

| Noise Level | <70 dB | – |

Certifications: CE, ISO 9001, ASTM D8580, GRI-GM13.

These specs ensure 95% project compatibility, with seams resisting 80+ chemicals for 50–100 years, per ASTM D5747.

6. Applications Driving Demand for Geomembrane Welders

Geomembrane welders are indispensable across industries, with applications influencing equipment choice and cost.

Landfill Liner Installation (40% Demand)

- Purpose:Weld HDPE liners (1.0–2.5 mm) to prevent leachate leaks.

- Welder Type:Hot wedge (dual-track, $5,000–$20,000).

- Case Study:BPM’s Leister TWINNY T7 welded 50,000 m² in Ecuador, achieving zero leaks in 30 days, 20% faster than average.

- Cost Impact:High seam strength requirements increase welder costs by 10–15%.

Mining Containment (25% Demand)

- Purpose:Seal tailings ponds and heap leach pads for chemical containment.

- Welder Type:Extrusion and hot wedge ($8,000–$20,000).

- Case Study:A Mongolian mine saved $300,000 in remediation using BPM’s Demtech VM-20 welders.

- Cost Impact:Thick liners (1.5–3 mm) demand robust welders, adding 5–10% to costs.

Water Containment (20% Demand)

- Purpose:Join liners for reservoirs, canals, and aquaculture ponds.

- Welder Type:Hot wedge and hot air ($2,000–$15,000).

- Case Study:A Canadian 10,000 m² leachate pond used BPM’s Leister COMET, ensuring zero leakage.

- Cost Impact:Thinner liners (0.5–1.5 mm) reduce welder costs by 10%.

Wastewater Treatment (10% Demand)

- Purpose:Weld liners for sludge lagoons and clarifiers.

- Welder Type:Hot wedge and extrusion ($5,000–$15,000).

- Case Study:A Malaysian plant welded 15,000 m² with BPM’s fusion welders, cutting leaks by 95%.

- Cost Impact:Chemical resistance requirements add 5% to costs.

Other Applications (5% Demand)

- Aquaculture:Hot air welders ($2,000–$8,000) for PVC liners.

- Oil and Gas:Extrusion welders ($8,000–$15,000) for spill containment.

- Construction:Hot wedge welders ($5,000–$20,000) for foundation liners.

Diverse applications drive demand for versatile welders, increasing costs for multi-material compatibility.

7. Benefits of Investing in Quality Welders

High-quality welders justify their cost through long-term savings and performance:

Leak Prevention

Seams achieve 99% impermeability, reducing contamination risks by 95%, per EPA studies. Electronic leak location surveys (ELLS) detect 99% of defects, per ASTM D7953.

Efficiency Gains

Automated welders weld 500–1000 m²/day, 40% faster than manual methods, saving $0.5–$1/m² in labor, per Leister. IoT monitoring cuts rework by 15%.

Durability

Seams resist 50–100 years of chemical and UV exposure with proper cover, per ASTM D7238, saving $0.5–$1/m² in repairs over 20 years.

Regulatory Compliance

Welders meet:

- EPA (U.S.):≥90% seam strength, per 40 CFR Part 258.

- EU (EN 13492):Dual-track seams, per ASTM D6392.

- China (CJQJ17):≥85% peel strength, per CJ/T 234-2006.

Compliance reduces legal risks, saving 5–10% on penalties.

8. Cost-Saving Tips for Geomembrane Welders

Maximize ROI with these strategies:

Rent vs. Buy

- Rent:$100–$500/day for short-term projects (<1 month). Saves 50% on upfront costs but adds 20% to long-term expenses.

- Buy:Ideal for projects >3 months or multiple sites. Amortized over 5 years, costs drop to $0.1–$0.4/m².

Bulk Purchasing

Order multiple units or combine with geomembranes to save 15–20%, per Alibaba. BPM offers 10% discounts on orders >$50,000.

Choose Mid-Range Brands

QIVOC or Weldy welders ($5,000–$15,000) offer 90% of premium performance at 50% lower cost, with 1–2-year warranties.

Invest in Training

Certified operators reduce seam failures by 20%, saving $0.2–$0.5/m² in repairs, per Geosynthetics Institute. BPM provides free training with purchases.

Maintain Equipment

Regular cleaning and sensor replacement ($500–$2,000/year) extend welder life by 3–5 years, saving $2,000–$5,000, per Leister.

Plan Logistics

Order 1–2 months ahead to avoid rush fees (5–10%). Consolidate shipments to save 10–15% on transport, per BPM guidelines.

9. How to Choose the Right Geomembrane Welder

Selecting the optimal welder saves 20% on costs and boosts efficiency by 25%. Consider:

Project Requirements

- Material/Thickness:HDPE (1–3 mm) needs hot wedge welders; PVC (0.2–1 mm) suits hot air welders.

- Scale:Small projects (<10,000 m²) use handheld welders; large projects (>50,000 m²) need fusion welders.

- Site Conditions:Slopes require track-driven welders; remote sites need DC/battery models.

Budget Constraints

- Short-Term:Rent or buy budget welders ($1,000–$8,000).

- Long-Term:Invest in semi-automatic welders ($10,000–$20,000) for 5+ years of use.

Supplier Reliability

- Certifications:Ensure CE, ISO 9001, and ASTM D8580 compliance.

- Warranty:Prefer 2–3 years for premium brands, 1 year for mid-range.

- Support:Choose suppliers like BPM with 24/7 service and spare parts availability.

Feature Needs

- Automation:IoT and robotic tracking for large projects.

- Portability:Lightweight models for remote sites.

- Testing:Integrated seam testing for high-risk applications.

10. Conclusion

Geomembrane welding machine prices in 2025 range from $1,000 for handheld models to $50,000 for automated fusion welders, driven by type, automation, material compatibility, and features. With the geomembrane market growing at 5.4% annually, investing in quality welders from trusted manufacturers like BPM Geosynthetics ensures 99% seam impermeability and 50–100-year durability. Hot wedge welders ($5,000–$20,000) dominate for landfills and mining, while hot air welders ($2,000–$8,000) suit aquaculture. Automation and IoT features add 10–20% to costs but save 30% on labor, delivering $0.5–$1/m² in long-term savings. By renting for short-term projects, buying mid-range brands, and training operators, you can reduce costs by 20–30%.

Contact BPM Geosynthetics to explore geomembrane welders, request demos, and optimize your containment projects with factory-direct pricing and global support.