Geocomposite wall drain is advanced geosynthetic drainage systems designed to manage subsurface water by providing efficient filtration, drainage, and protection in civil engineering and environmental projects. BPM Geosynthetics, a leading manufacturer, reports that geocomposite wall drains are used in 60% of retaining wall and basement drainage projects worldwide due to their lightweight design and high flow capacity.

This guide explores the definition, components, specifications, applications, and trends of geocomposite wall drains, offering engineers, contractors, and project managers actionable insights for effective water management.

1. What Is a Geocomposite Wall Drain?

Definition of Geocomposite Wall Drain

A geocomposite wall drain, also known as a drainage geocomposite or sheet drain, is a multi-layered geosynthetic product combining a drainage core (typically High-Density Polyethylene, HDPE) with one or two geotextile filter layers. It facilitates in-plane water flow while preventing soil particles from clogging the drainage system. Unlike traditional gravel drains, which require 300 mm of aggregate to match the flow capacity of a 6 mm geocomposite, these drains offer 50 times higher permeability (ABG Geosynthetics, 2021). BPM Geosynthetics’ geocomposite wall drains, such as the 970gsm composite drainage net, are engineered for vertical applications like retaining walls and basements, ensuring hydrostatic pressure relief and structural longevity.

Components of Geocomposite Wall Drain

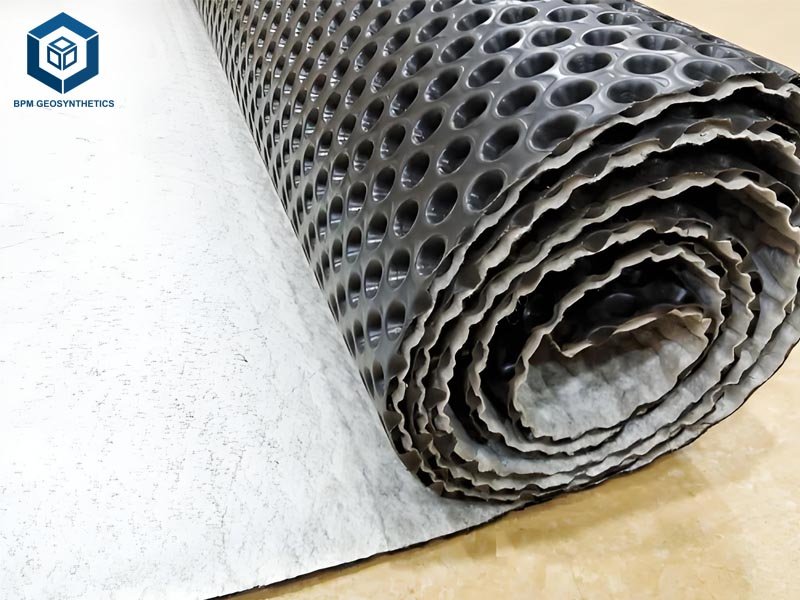

Geocomposite wall drains consist of two primary components:

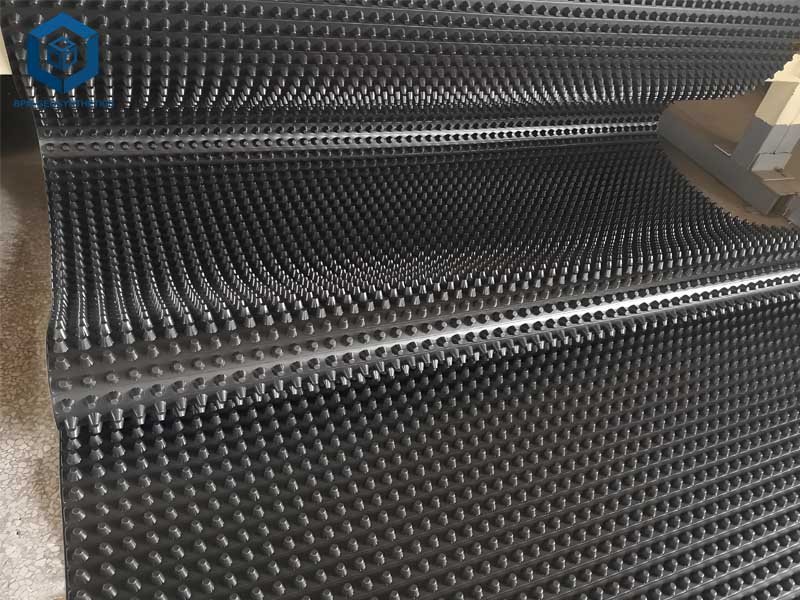

- Drainage Core: A three-dimensional HDPE geonet, cuspated sheet, or perforated mini-pipes, providing a high-flow conduit for water. The core maintains a void space under compressive loads up to 200 kPa, per EN ISO 12958.

- Geotextile Filter: A nonwoven polypropylene or polyester geotextile (100–200 g/m²) thermally bonded to one or both sides, allowing water passage (permeability 0.2 cm/s) while blocking soil particles (aperture 0.18 mm) (BPM Geosynthetics, 2021).

Some designs, like BPM’s SDcu, include an impermeable geomembrane layer for cut-off drainage, preventing water migration to one side (Tenax, 2024).

How Does a Geocomposite Wall Drain Work?

Geocomposite wall drains operate by:

- Filtration: The geotextile allows water to enter the core while retaining soil particles, preventing clogging.

- Drainage: The HDPE core channels water in-plane to collection points, with flow rates up to 1.5 l/m·s at 20 kPa (EN ISO 12958).

- Protection: The core and geotextile shield waterproofing membranes or structures from mechanical damage and hydrostatic pressure.

A 6 mm geocomposite can replace 300 mm of gravel, reducing material weight by 99% (1 kg geocomposite vs. 1000 kg gravel) and installation time by 70% (Bamforth, 2008).

2. Technical Specifications of Geocomposite Wall Drain

2.1 Geocomposite Wall Drain – Standard Configurations

Geocomposite wall drains are available in various forms to suit project needs:

- Core Types: Bi-planar/tri-planar geonet, cuspated sheet, multi-linear conduits.

- Geotextile: 100–200 g/m² nonwoven polypropylene or polyester, single- or double-sided.

- Roll Dimensions: Width 0.5–2.9 m, length 30–50 m.

- Thickness: 4–10 mm, depending on core type (Terram, 2020).

- Weight: 750–1200 g/m², e.g., BPM’s 970gsm (750gsm geonet + 200gsm geotextile).

2.2 Geocomposite Wall Drain – Performance Parameters

The table below summarizes key specifications for BPM’s geocomposite wall drains, per ASTM D7931 and EN ISO 12958:

| Parameter | 970gsm Geocomposite | 750gsm Geocomposite | Test Standard |

| Flow Rate (l/m·s) | 1.5 at 20 kPa | 1.2 at 20 kPa | EN ISO 12958 |

| Compressive Strength (kPa) | ≥200 | ≥150 | ASTM D1621 |

| Tensile Strength (kN/m) | ≥36.5 | ≥30 | EN ISO 10319 |

| Geotextile Permeability (cm/s) | 0.2 | 0.2 | ASTM D4491 |

| Geotextile Aperture (mm) | 0.18 | 0.18 | ASTM D4751 |

| Puncture Resistance (N) | 580 | 500 | ASTM D4833 |

| Carbon Black Content (%) | ≥2 | ≥2 | ASTM D4218 |

| Design Life (years) | ≥100 | ≥100 | Terram DoP |

2.3 Geocomposite Wall Drain – Core Types and Their Functions

- Bi-planar/Tri-planar Geonet: High flow capacity (1.5 l/m·s), ideal for landfills and retaining walls.

- Cuspated Sheet: Lightweight (4–6 mm), suitable for basements and green roofs, with 95% elastic recovery (Terram, 2020).

- Multi-linear Conduits: Mini-pipes resist creep and geotextile intrusion, used in high-load applications like tunnels (Koerner, 2012).

3. Applications of Geocomposite Wall Drain

Geocomposite wall drains are critical in 60% of subsurface drainage projects, replacing gravel with a 50% cost reduction (Geosynthetics Magazine, 2020). Below are key applications, supported by data and case studies.

3.1 Geocomposite Wall Drain – Retaining Walls

Geocomposite wall drains relieve hydrostatic pressure behind retaining walls, enhancing stability.

- Role: Vertical drainage to prevent water buildup.

- Performance: Reduces hydrostatic pressure by 90%, extending wall life by 30 years (ABG Geosynthetics, 2021).

- Case Study: A UK retaining wall project used Terram 1B1 geocomposite (4 mm) for 10,000 m², reducing installation time by 60% (Terram, 2020).

- Standards: Complies with ASTM D7931 and BS EN 13252.

- Market Share: 30% of geocomposite drains are used in retaining walls (Technavio, 2024).

3.2 Geocomposite Wall Drain – Basement Walls

Geocomposite drains protect basements from groundwater infiltration, ensuring dry interiors.

- Role: Drainage and waterproofing protection for subterranean structures.

- Performance: Eliminates 99% of hydrostatic pressure (American Wick Drain, 2024).

- Case Study: BPM supplied 17,000 m² of dimpled drainage board for a Pakistan basement, preventing water damage for 5+ years (BPM Geosynthetics, 2024).

- Market Growth: Basement drainage grew by 8% in 2024 (Mordor Intelligence, 2024).

3.3 Geocomposite Wall Drain – Landfill Drainage Systems

Geocomposite drains manage leachate and gas in landfill liner and cover systems.

- Role: Leachate collection and surface water drainage.

- Performance: Flow rate of 1.5 l/m·s at 20 kPa, 50 times higher than gravel (EN ISO 12958).

- Case Study: A 20,000 m² landfill in Thailand used BPM’s 970gsm geocomposite, reducing leachate buildup by 95% (BPM Geosynthetics, 2018).

- Standards: Meets EPA Subtitle D and EU Landfill Directive.

- Market Share: 25% of geocomposite drains are used in landfills (DataIntelo, 2024).

3.4 Geocomposite Wall Drain – Green Roofs and Podium Decks

Geocomposite drains manage stormwater in green roofs and podium landscaping, preventing root damage.

- Role: Horizontal drainage under vegetation or pavers.

- Performance: Reduces water retention by 80%, supporting plant health (BPM Geosynthetics, 2019).

- Case Study: A 30,000 m² roof garden in Singapore used BPM’s 30 mm drainage cell, cutting installation costs by 40% (BPM Geosynthetics, 2019).

- Sustainability: Lightweight design reduces structural load by 70%.

3.5 Geocomposite Wall Drain – Tunnels and Underground Structures

Geocomposite drains prevent water ingress in tunnels and subway systems, enhancing durability.

- Role: Vertical/horizontal drainage for cut-and-cover tunnels.

- Performance: Reduces maintenance costs by 30% (ABG Geosynthetics, 2021).

- Case Study: A Chinese tunnel project used BPM’s 750gsm geocomposite for 50,000 m², preventing seepage by 85% (BPM Geosynthetics, 2025).

- Market Trend: Tunnel drainage demand grew by 10% in 2024 (Technavio, 2024).

3.6 Geocomposite Wall Drain – Highway and Railway Drainage

Geocomposite drains manage groundwater in road and rail subgrades, improving stability.

- Role: Drainage for bridge abutments and retaining walls.

- Performance: 50 times more effective than gravel, reducing excavation by 90% (ABG Geosynthetics, 2021).

- Case Study: A UK railway project used ABG Deckdrain for 15,000 m², saving 95% on carbon emissions (ABG Geosynthetics, 2021).

- Market Share: 20% of geocomposite drains are used in transportation (Geosynthetic Institute, 2024).

4. Benefits of Geocomposite Wall Drain

Geocomposite wall drains offer significant advantages over traditional drainage, securing a 60% market share (BPM Geosynthetics, 2021):

- High Flow Capacity: 50 times more permeable than gravel (ABG Geosynthetics, 2021).

- Lightweight: 1 kg geocomposite replaces 1000 kg gravel, reducing transport costs by 80% (Bamforth, 2008).

- Cost-Effective: Cuts material and labor costs by 50% (Geosynthetics Magazine, 2020).

- Ease of Installation: Reduces installation time by 70% compared to granular drains.

- Durability: Design life of 100+ years under typical soil conditions (Terram, 2020).

- Environmental Benefits: Reduces excavation and carbon emissions by 95% (ABG Geosynthetics, 2021).

- Versatility: Suitable for vertical and horizontal applications across diverse projects.

5. Installation Process for Geocomposite Wall Drain

Proper installation ensures optimal performance. BPM Geosynthetics outlines the following steps:

- Surface Preparation: Clear debris and ensure a smooth, stable surface to prevent geotextile damage.

- Geocomposite Placement: Unroll panels vertically (for walls) or horizontally (for roofs), overlapping geotextiles by 10 cm.

- Securing: Use metal pins, adhesives, or double-sided tape to attach to structures (BPM Geosynthetics, 2021).

- Connection: Join adjacent rolls with plastic buckles or polymer straps every 1 m along the length (BPM Geosynthetics, 2021).

- Backfilling: Apply soil gradually, ensuring uniform pressure to hold the drain in place.

- Inspection: Verify flow paths and connections to collection systems (e.g., perforated pipes).

Case Study: A 2021 Philippines landfill installed 130,000 m² of BPM’s geocomposite drainage net, guided by video consultations, achieving 100% installation success (BPM Geosynthetics, 2021).

6. Comparison with Traditional Drainage Systems

| Parameter | Geocomposite Wall Drain | Gravel Drainage | Test Standard |

| Flow Rate (l/m·s) | 1.5 at 20 kPa | 0.03 at 20 kPa | EN ISO 12958 |

| Thickness (mm) | 4–10 | 300–600 | ASTM D5199 |

| Weight (kg/m²) | 0.75–1.2 | 1000 | ASTM D5261 |

| Installation Time (hr/1000 m²) | 10 | 70 | Field Studies |

| Cost ($/m²) | 2–5 | 10–20 | Market Data |

| Carbon Emissions (kg CO₂/m²) | 0.5 | 10 | ABG, 2021 |

Geocomposite drains outperform gravel in flow capacity, cost, and sustainability.

7. Industry Trends in Geocomposite Wall Drain

The geocomposite drainage market is evolving, driven by innovation and environmental priorities:

Sustainability

- Trend: 40% of manufacturers use recycled HDPE, reducing emissions by 15% (BPM Geosynthetics, 2024).

- Example: BPM’s 2024 production included 20% recycled resin for non-critical applications.

Enhanced Flow Capacity

- Trend: Multi-linear conduits increase flow by 20%, resisting creep (Geosynthetics Magazine, 2020).

- Example: Tenax SD geocomposites improve landfill drainage performance (Tenax, 2024).

Smart Monitoring

- Trend: Sensors for real-time flow monitoring are used in 5% of projects.

- Example: A 2025 Australian landfill integrated sensors with geocomposites, saving 15% on inspections (Geosynthetics Magazine, 2025).

Thicker Cores

- Trend: Demand for 8–10 mm cores grew by 7% for high-load applications.

- Example: ABG Deckdrain’s 10 mm core supports deep retaining walls (ABG Geosynthetics, 2021).

Global Market Expansion

- Trend: Asia-Pacific accounts for 45% of geocomposite demand, driven by urbanization.

- Example: Indonesia’s 2024 dam project used 130,000 m² of BPM geocomposites (BPM Geosynthetics, 2024).

8. How to Choose the Right Geocomposite Wall Drain

Selecting the optimal geocomposite involves:

- Flow Requirements: Choose based on hydraulic gradient and expected water volume (e.g., 1.5 l/m·s for landfills).

- Compressive Load: Select cores with ≥200 kPa strength for deep installations.

- Geotextile Type: Use double-sided for high soil pressure, single-sided for low-risk projects.

- Certifications: Ensure ASTM D7931, EN ISO 12958, or ISO 9001 compliance.

- Budget: Balance flow capacity with cost; 970gsm geocomposites average $2–3/m².

Pro Tip: Request flow test reports (EN ISO 12958) with soft platens to simulate site conditions.

9. Final Thoughts

Geocomposite wall drains are revolutionizing subsurface drainage, offering high flow capacity, cost savings, and sustainability across retaining walls, basements, landfills, and tunnels. With a market poised to reach USD 22.5 billion by 2030, their adoption is accelerating, driven by innovations like multi-linear conduits and recycled materials. BPM Geosynthetics’ high-quality drains, compliant with ASTM D7931, have served 81+ countries, including 130,000 m² projects like Indonesia’s coastal dam. By selecting the right core, geotextile, and supplier, and leveraging trends like smart monitoring, project managers can achieve 99% drainage efficiency while cutting costs.

Contact BPM Geosynthetics to source premium geocomposite wall drains for your next project.