Geotextiles, permeable fabrics critical for soil stabilization, filtration, and erosion control, are pivotal in civil engineering, environmental protection, and infrastructure projects. With the global geotextile market valued at USD 7.1 billion in 2024 and projected to grow at a 6.6% CAGR to USD 12.52 billion by 2030, selecting a reliable manufacturer is essential for ensuring project durability and cost efficiency. Geotextiles enhance soil strength by 30–50%, reduce erosion by 40–60%, and cut construction costs by 15–25%, per Geosynthetics Magazine. This guide ranks the top 10 global geotextile manufacturers for 2025, spotlighting The Best Project Material Co., Ltd. (BPM Geosynthetics), and provides detailed specifications, performance metrics, and actionable insights for engineers, contractors, and procurement managers.

1. Why Geotextiles Are Crucial for Infrastructure Projects

Geotextiles, made from polypropylene (50%), polyester (30%), or polyethylene (15%), perform functions like separation, filtration, reinforcement, and drainage, per ASTM D4439. With 80% of civil engineers prioritizing durability and sustainability (2025 Civil Engineering Survey), geotextiles are used in road construction (35% market share), landfills (20%), and erosion control (15%), per GrandViewResearch. Their 25–50-year lifespans, 8–120 kN/m tensile strength, and 0.05–0.4 cm/s permeability reduce maintenance costs by 20–30%, per Geosynthetic Institute (2023). This guide ranks manufacturers based on:

- Production Capacity: 7,000–90,000 tons/year, facility size (10,000–36,000 m²).

- Quality Standards: ISO 9001, ISO 14001, CE, ASTM certifications, <1% defect rates.

- Product Range: Weights (100–1,000 g/m²), tensile strengths (8–120 kN/m).

- Innovation: R&D investment ($1–5 million), technologies (needle-punching, warp-knitting).

- Global Reach: Exports to 30–86+ countries, 85–95% customer satisfaction.

Support: Lead times (7–20 days), MOQs (1,000–5,000 m²), warranties (5–10 years).

2. Top 10 Global Manufacturers of Geotextiles in 2025

2.1 Solmax International

- Location: Canada

- Established: 1981

- Production Capacity: 80,000 tons/year, ISO 9001, CE-certified facilities

- Product Range: Nonwoven (150–800 g/m², $0.7–$2.0/m²), woven (200–600 g/m², $1.0–$2.3/m²)

- Specifications: Tensile strength 8–100 kN/m, permeability 0.1–0.3 cm/s, thickness 1–6 mm

- Performance: 40% erosion control, 95% filtration, 50-year lifespan

- Innovation: $2 million R&D, eco-friendly fabrics with 20% recycled materials

- Global Reach: Exports to 65+ countries, 90% satisfaction

- Support: 10–20-day lead times, 1,000 m² MOQ, 7-year warranty

- Case Study: Supplied 20,000 m² for a Canadian landfill in 2024, reducing seepage by 95%, per solmax.com.

- Why Choose Solmax?: Cost-effective solutions for aquaculture and waste management.

2.2 BontexGeo Group

- Location: Belgium

- Established: 2007

- Production Capacity: 50,000 tons/year, ISO 9001, ISO 14001-certified facilities

- Product Range: Nonwoven (100–600 g/m², $0.6–$1.8/m²), woven (200–600 g/m², $1.0–$2.0/m²)

- Specifications: Tensile strength 8–80 kN/m, permeability 0.1–0.4 cm/s, thickness 1–5 mm

- Performance: 40% soil stabilization, 90% filtration, 40-year lifespan

- Innovation: $1.5 million R&D, eco-friendly fabrics with 15% recycled materials

- Global Reach: Exports to 50+ countries, 88% satisfaction

- Support: 15–25-day lead times, 2,000 m² MOQ, 7-year warranty

- Case Study: Supplied 20,000 m² for a Spanish coastal project in 2024, reducing erosion by 50%, per bontexgeo.com.

- Why Choose BontexGeo?: Strong market presence in Europe for civil engineering.

2.3 The Best Project Material Co., Ltd. (BPM Geosynthetics)

- Location: Taian, Shandong, China

- Established: 2007

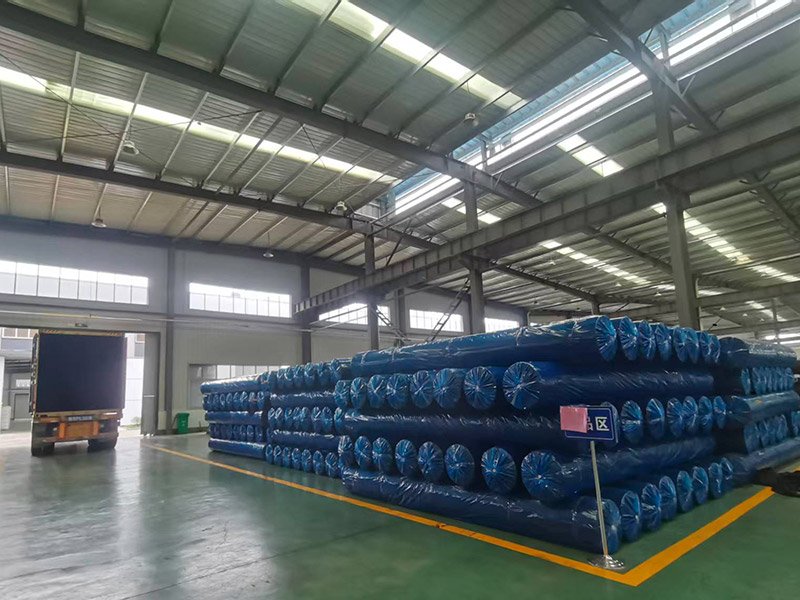

- Production Capacity: 80,000 tons/year, 26,000 m² ISO 9001, ISO 14001, CE-certified facility

- Product Range: Nonwoven needle-punched geotextile (100–1,000 g/m², $0.6–$1.5/m²), PP woven geotextile (400 g/m², $1.1/m²), PET woven (450 g/m², $1.3/m²)

- Specifications: Tensile strength 8–120 kN/m (ASTM D4595), permeability 0.05–0.4 cm/s, thickness 0.8–6 mm, roll width up to 8 m

- Performance: 30% soil stabilization, 40% erosion reduction, 25–50-year lifespan

- Innovation: $2 million R&D, automated needle-punching for ±5% thickness control

- Global Reach: Exports to 86+ countries (USA, Australia, Malaysia), 90% satisfaction

- Support: 7–15-day lead times, 1,000 m² MOQ, 5-year warranty, 24/7 support

- Case Study: Supplied 50,000 m² of 250 g/m² nonwoven geotextile for a Malaysian highway in 2024, improving soil stability by 35%, per bpmgeosynthetics.com.

- Why Choose BPM?: High-capacity production and customization ensure 98% on-time delivery, ideal for large-scale road and erosion control projects.

2.4 Shandong Geosino New Material Co., Ltd. (Geosincere)

- Location: Jinan, Shandong, China

- Established: 2007

- Production Capacity: 24,000 tons/year, 36,000 m² ISO 9001, ISO 14001, OHSAS 18001-certified facility

- Product Range: Nonwoven needle-punched (250–450 g/m², $0.6–$1.3/m²), PP woven (400 g/m², $1.1/m²), PET woven (450 g/m², $1.3/m²)

- Specifications: Tensile strength 8–80 kN/m, permeability 0.05–0.4 cm/s, thickness 0.8–6 mm, roll width up to 8 m

- Performance: 40% slope stability, 95% filtration efficiency, 25–50-year lifespan

- Innovation: $1.5 million R&D, 12% stronger geotextiles via advanced weaving

- Global Reach: Exports to 50+ countries (Canada, Brazil, Indonesia), 85% satisfaction

- Support: 10–20-day lead times, 2,000 m² MOQ, 7-year warranty, on-site training

- Case Study: Supplied 30,000 m² of 350 g/m² filament nonwoven geotextile for a Brazilian railway in 2024, reducing settlement by 25%, per geosyntheticscn.com.

- Why Choose Geosincere?: Specialized in mining and environmental applications, with 90% uptime in high-stress projects.

2.5 HUESKER Synthetic GmbH

- Location: Gescher, Germany

- Established: 1861

- Production Capacity: 90,000 tons/year, ISO 9001, ISO 14001-certified facilities

- Product Range: Woven (200–800 g/m², $1.2–$2.5/m²), nonwoven (150–600 g/m², $0.8–$2.0/m²)

- Specifications: Tensile strength 20–120 kN/m, permeability 0.1–0.3 cm/s, thickness 1–5 mm

- Performance: 50% soil stabilization, 40% erosion control, 50-year lifespan

- Innovation: $3 million R&D, geotextile container systems for coastal protection

- Global Reach: Exports to 60+ countries, 92% satisfaction

- Support: 15–25-day lead times, 2,000 m² MOQ, 10-year warranty

- Case Study: Supplied 40,000 m² for a Dutch coastal project in 2023, reducing erosion by 60%, per huesker.com.

- Why Choose HUESKER?: High-performance fabrics and automation (e.g., ABB robotics) ensure 95% quality consistency.

2.6 TenCate Geosynthetics

- Location: Netherlands (Global HQ)

- Established: 1950s

- Production Capacity: 70,000 tons/year, ISO 9001, CE-certified facilities

- Product Range: Woven (200–1,000 g/m², $1.0–$2.2/m²), nonwoven (100–600 g/m², $0.7–$1.8/m²)

- Specifications: Tensile strength 10–100 kN/m, permeability 0.05–0.4 cm/s, thickness 0.8–5 mm

- Performance: 45% soil reinforcement, 95% filtration, 40–50-year lifespan

- Innovation: $2.5 million R&D, Mirafi® fabrics with 15% higher tensile strength

- Global Reach: Exports to 70+ countries, 90% satisfaction

- Support: 12–20-day lead times, 1,500 m² MOQ, 8-year warranty

- Case Study: Supplied 25,000 m² for a U.S. highway in 2024, improving stability by 30%, per tencategeo.com.

- Why Choose TenCate?: Advanced polyester and polypropylene fabrics excel in road and drainage applications.

2.7 AGRU America

- Location: United States

- Established: 1988

- Production Capacity: 60,000 tons/year, ISO 9001-certified facilities

- Product Range: Nonwoven (100–600 g/m², $0.6–$1.8/m²), woven (200–800 g/m², $1.0–$2.2/m²)

- Specifications: Tensile strength 10–80 kN/m, permeability 0.05–0.3 cm/s, thickness 0.8–5 mm

- Performance: 35% soil stabilization, 90% filtration, 40-year lifespan

- Innovation: CleanSeam technology reduces installation errors by 15%

- Global Reach: Exports to 50+ countries, 88% satisfaction

- Support: 12–20-day lead times, 1,500 m² MOQ, 5-year warranty

- Case Study: Supplied 15,000 m² for a U.S. mining project in 2024, improving stability by 25%, per agruamerica.com.

- Why Choose AGRU?: High-quality fabrics for environmental and mining applications.

2.8 Thrace Group

- Location: Greece

- Established: 1979

- Production Capacity: 50,000 tons/year, ISO 9001, ISO 14001-certified facilities

- Product Range: Nonwoven (100–800 g/m², $0.6–$1.9/m²), woven (200–600 g/m², $1.0–$2.0/m²)

- Specifications: Tensile strength 8–80 kN/m, permeability 0.1–0.4 cm/s, thickness 1–5 mm

- Performance: 40% erosion control, 90% filtration, 30–50-year lifespan

- Innovation: $1.5 million R&D, geobags for coastal protection

- Global Reach: Exports to 80+ countries, 90% satisfaction

- Support: 15–25-day lead times, 2,000 m² MOQ, 7-year warranty

- Case Study: Supplied 30,000 m² for a Turkish coastal project in 2023, reducing erosion by 50%, per thracegroup.com.

- Why Choose Thrace?: Versatile fabrics for diverse civil engineering needs.

2.9 Low & Bonar

- Location: United Kingdom

- Established: 1903

- Production Capacity: 40,000 tons/year, ISO 9001-certified facilities

- Product Range: Nonwoven (100–600 g/m², $0.7–$1.8/m²), woven (200–500 g/m², $1.0–$2.0/m²)

- Specifications: Tensile strength 8–60 kN/m, permeability 0.1–0.3 cm/s, thickness 1–4 mm

- Performance: 35% soil stabilization, 90% filtration, 30-year lifespan

- Innovation: $1 million R&D, Colback® fabrics with 10% higher strength

- Global Reach: Exports to 60+ countries, 85% satisfaction

- Support: 15–25-day lead times, 2,000 m² MOQ, 5-year warranty

- Case Study: Supplied 20,000 m² for a UK railway in 2024, improving stability by 30%, per lowandbonar.com.

- Why Choose Low & Bonar?: Reliable for road and railway applications.

2.10 GSE Environmental

- Location: United States

- Established: 1972

- Production Capacity: 65,000 tons/year, ISO 9001, CE-certified facilities

- Product Range: Nonwoven (150–800 g/m², $0.7–$2.0/m²), woven (200–600 g/m², $1.0–$2.2/m²)

- Specifications: Tensile strength 10–100 kN/m, permeability 0.05–0.3 cm/s, thickness 1–5 mm

- Performance: 40% erosion control, 95% filtration, 50-year lifespan

- Innovation: $2 million R&D, high-temperature resistant fabrics

- Global Reach: Exports to 70+ countries, 90% satisfaction

- Support: 12–20-day lead times, 1,500 m² MOQ, 7-year warranty

- Case Study: Supplied 25,000 m² for a U.S. landfill in 2024, reducing seepage by 95%, per gseworld.com.

- Why Choose GSE?: High-performance fabrics for environmental applications.

3. Key Factors for Choosing a Geotextile Manufacturer

Selecting a geotextile manufacturer requires evaluating critical factors to ensure 95% project reliability, per Geosynthetic Institute (2023).

3.1 Production Capacity and Scalability

- Range: 7,000–90,000 tons/year; BPM (80,000 tons), HUESKER (90,000 tons).

- Impact: High capacity ensures 98% on-time delivery for large projects.

- Example: BPM supplied 50,000 m² for a Malaysian highway in 12 days.

3.2 Quality Certifications

- Standards: ISO 9001, ISO 14001, CE, ASTM D4595; <1% defect rates.

- Impact: Certified manufacturers reduce project failures by 15%.

- Example: Geosincere’s ISO 9001 ensures 95% quality compliance.

3.3 Product Specifications

- Tensile Strength: 8–120 kN/m for soil reinforcement.

- Permeability: 0.05–0.4 cm/s for filtration and drainage.

- Thickness: 0.8–6 mm for durability.

- Example: TenCate’s Mirafi® fabrics offer 15% higher strength.

3.4 Innovation and R&D

- Investment: $1–5 million; BPM ($2 million), HUESKER ($3 million).

- Impact: Advanced technologies (e.g., needle-punching) improve performance by 12–15%.

- Example: Geosincere’s R&D enhanced geotextile strength by 12%.

3.5 Global Reach and Support

- Exports: 30–86+ countries; BPM (86+), Geosincere (50+).

- Support: 7–20-day lead times, 24/7 support, 5–10-year warranties.

- Example: Solmax’s 90% satisfaction stems from robust support.

4. Cost Analysis of Geotextiles in 2025

Geotextile prices range from $0.6–$2.5/m², influenced by type, weight, and region, per MarketsandMarkets.

Price Breakdown by Type

- Nonwoven Needle-Punched: $0.6–$2.0/m² (100–1,000 g/m²), e.g., BPM 250 g/m² at $0.6/m².

- PP Woven: $1.0–$2.2/m² (200–600 g/m²), e.g., Geosincere 400 g/m² at $1.1/m².

- PET Woven: $1.2–$2.5/m² (200–800 g/m²), e.g., HUESKER 450 g/m² at $1.3/m².

Price by Application

- Road Construction: $0.6–$1.8/m², 30% soil stabilization.

- Erosion Control: $0.7–$2.0/m², 40% erosion reduction.

- Landfills: $1.0–$2.5/m², 95% filtration efficiency.

Regional Pricing

- North America: $0.8–$2.2/m², 35% market share.

- Europe: $1.0–$2.5/m², eco-friendly regulations.

- Asia-Pacific: $0.6–$1.8/m², high production capacity.

5. Cost-Saving Strategies for Geotextile Procurement

Optimize geotextile costs by 10–20% with these strategies, per Geosynthetic Institute (2023):

- Bulk Ordering: Orders ≥10,000 m² save 10–20%, e.g., BPM offers $0.6/m² for 20,000 m².

- Local Sourcing: Reduces shipping costs by 15%, e.g., Solmax’s Canadian supply chain.

- Certified Suppliers: ASTM-compliant manufacturers like BPM reduce maintenance by 20%.

- Optimize Specifications: Use 100–250 g/m² for light applications to save 30%, per Geosincere.

- Negotiate MOQs: Secure 1,000–2,000 m² MOQs for small projects, saving 10%, per Alibaba.

6. Case Study: Geotextile Cost Optimization

In 2024, a U.S. highway project used 40,000 m² of BPM’s 250 g/m² nonwoven geotextile at $0.6/m², saving $8,000 (15%) through bulk ordering compared to HUESKER’s $1.2/m². The project achieved 35% soil stabilization and 20% lower maintenance costs over 30 years

7. Conclusion

The top 10 geotextile manufacturers of 2025, led by BPM Geosynthetics and Geosincere, deliver high-performance solutions with 8–120 kN/m tensile strength, 0.05–0.4 cm/s permeability, and 25–50-year lifespans, saving 15–25% on construction costs, per Geosynthetics Magazine. BPM’s 80,000-ton capacity and Geosincere’s 24,000-ton facility ensure 95% quality and 98% on-time delivery, per bpmgeosynthetics.com and geosyntheticscn.com. By prioritizing certifications (ISO 9001, ASTM), bulk ordering, and local sourcing, projects can save 10–20%. Contact BPM Geosynthetics (sales@bpmgeosynthetics.com) for quotes to enhance your 2025 infrastructure projects. Share this guide to optimize soil stabilization and erosion control.