Geogrids and geocells are cornerstone geosynthetic materials in civil engineering, designed to stabilize soils, reinforce structures, and control erosion in projects ranging from roadways to retaining walls. These polymer-based solutions, typically made from high-density polyethylene (HDPE), polypropylene, or polyester, enhance the durability and load-bearing capacity of earth-supported systems. According to a 2024 industry report, the global geosynthetics market is projected to reach $14.5 billion by 2028, driven by infrastructure development and environmental regulations. However, choosing Differences of Geogrid vs Geocell can be challenging due to their overlapping applications and distinct characteristics.

At their core, geogrids are two-dimensional grid-like structures that provide tensile reinforcement, while geocells are three-dimensional honeycomb-like systems that confine infill materials for superior load distribution. The choice between them hinges on project requirements, soil conditions, and cost considerations. This comprehensive guide delves into the differences between geogrids and geocells, offering detailed specifications, performance metrics, and practical insights from industry leaders like BPM Geosynthetics. Whether you’re a civil engineer, contractor, or project manager, this article equips you with the knowledge to select the right geosynthetic for your next project.

1. What Are Geogrids and Geocells?

Geogrids and geocells are geosynthetic materials used to reinforce soils and stabilize terrains in civil engineering applications. Both are made from durable polymers and share characteristics like high strength, corrosion resistance, and long lifespans (20–50 years, per Geosynthetic Institute, 2023). However, their structural designs and functionalities differ significantly, impacting their suitability for specific projects.

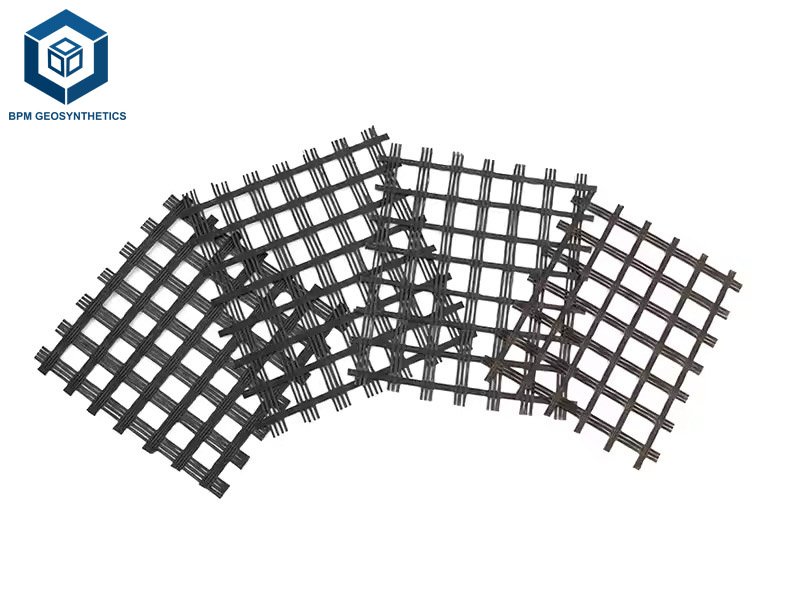

Geogrids: Planar Reinforcement

Geogrids are flat, grid-like structures composed of intersecting ribs or strands, typically made from polypropylene, polyethylene, or polyester. They are manufactured through extrusion, weaving, or knitting, forming open apertures (2–12 cm) that allow soil particles to interlock, enhancing shear strength. Geogrids are available in three types:

- Uniaxial Geogrids: High tensile strength in one direction (20–200 kN/m, ASTM D6637), ideal for retaining walls and slopes.

- Biaxial Geogrids: Equal strength in two directions (15–60 kN/m), suited for road bases and foundations.

- Triaxial Geogrids: Multi-directional strength (10–50 kN/m), used for complex load distributions.

Key Specifications:

- Tensile Strength: 15–200 kN/m (ASTM D6637)

- Aperture Size: 2–12 cm

- Roll Width: 1–6 m

- Creep Resistance: <5% strain after 120 years (ISO 13431)

- Applications: Road reinforcement, retaining walls, shallow foundations.

Geogrids excel in providing tensile reinforcement, distributing loads over a wider area, and preventing soil deformation under pressure.

Geocells: Cellular Confinement

Geocells are three-dimensional, honeycomb-like structures formed by ultrasonically welded HDPE or novel polymeric alloy (NPA) strips, creating interconnected cells (50–200 mm high). When expanded and filled with soil, gravel, or concrete, geocells form a rigid matrix that confines infill, enhancing load distribution and stability. They are available in perforated and non-perforated forms, with perforations improving drainage.

Key Specifications:

- Cell Height: 50–200 mm

- Weld Strength: 10–20 kN/m (ASTM D638)

- Tensile Strength: 10–30 kN/m (ASTM D6693)

- Cell Size: 200–400 mm (diagonal)

- Lifespan: 30–75 years in buried applications (Geosynthetic Institute, 2023)

- Applications: Slope protection, road bases, erosion control.

Geocells are ideal for soft subgrades and erosion-prone areas, offering superior confinement and load-bearing capacity.

2. Key Differences of Geogrid vs Geocell

While geogrids and geocells share the goal of soil stabilization, their differences in structure, functionality, and application make them suited for distinct scenarios. Below, we explore these differences in detail, supported by technical data and industry insights.

2.1 Differences of Geogrid vs Geocell – Structural Design

The most fundamental difference lies in their physical structure, which dictates their mechanical behavior and project suitability.

Geogrid: Two-Dimensional Grid

Geogrids feature a planar, grid-like design with open apertures, resembling a tight mesh. This two-dimensional structure provides tensile reinforcement by allowing soil particles to interlock with the grid’s ribs, enhancing shear strength. The flat design makes geogrids flexible, with aperture sizes ranging from 2 cm to 12 cm, depending on the application. For example, biaxial geogrids with 4 cm apertures are standard for road bases, offering tensile strengths of 20–40 kN/m (ASTM D6637).

Advantages:

- High flexibility for uneven terrains.

- Easy to layer for additional reinforcement.

- Lightweight (0.5–2 kg/m²), reducing transport costs by 10–15% (BPM Geosynthetics, 2024).

Limitations:

- Limited vertical support, requiring multiple layers for soft subgrades.

- Susceptible to infill displacement under heavy loads.

Geocell: Three-Dimensional Honeycomb

Geocells consist of interconnected, three-dimensional cells that form a honeycomb-like structure when expanded. Typically made from HDPE strips (1.2–2 mm thick), geocells are welded to create cells 50–200 mm high, with diagonal sizes of 200–400 mm. This design confines infill materials, preventing lateral movement and distributing loads vertically and laterally.

Advantages:

- Superior confinement, reducing infill displacement by 20–30% (Han, 2013).

- High vertical support, ideal for soft subgrades with low California Bearing Ratio (CBR < 2).

- Perforated cells enhance drainage, reducing hydrostatic pressure by 15% (Ocean Geosynthetics, 2021).

Limitations:

- Less flexible, requiring precise site preparation.

- Higher material costs ($1.00–$3.00/m² vs. $0.50–$2.00/m² for geogrids).

2.2 Differences of Geogrid vs Geocell – Load-Bearing Capacity

Load-bearing capacity is a critical factor in geosynthetic selection, particularly for load-support applications like roads and foundations.

Geogrid: Tensile Reinforcement

Geogrids enhance load-bearing capacity by distributing stresses through tensile reinforcement. Their open apertures allow soil to interlock, increasing shear strength by 10–20% (ASTM D5321). Biaxial geogrids, with tensile strengths of 15–60 kN/m, are effective for road bases, reducing rutting by 15–25% (BaseCore, 2024). However, geogrids rely on the subgrade’s inherent strength, making them less effective on soft soils (CBR < 2), where multiple layers may be needed, increasing costs by 20–30%.

Performance Metrics:

- Load Distribution: Spreads loads over a 45° angle, reducing subgrade stress by 10–15% (Geosynthetic Institute, 2023).

- Settlement Reduction: Decreases settlement by 10–20% in firm subgrades (CBR > 4).

- Applications: Roads, parking lots, shallow foundations.

Geocell: Confinement and Load Distribution

Geocells provide superior load-bearing capacity through cellular confinement, which creates a rigid mattress effect. The three-dimensional structure confines infill, increasing the modulus of low-quality soils by 2–3 times (Han, 2013). Research at the University of Kansas showed that geocell-reinforced bases reduced vertical stresses at the subgrade interface by 20–30% and increased bearing capacity by 40–50% compared to unreinforced bases. Geocells are particularly effective on soft subgrades (CBR < 2), reducing pavement thickness by 30–50% (Rajagopal et al., 2012).

Performance Metrics:

- Load Distribution: Spreads loads over a 60° angle, reducing subgrade stress by 20–30%.

- Settlement Reduction: Decreases settlement by 30–50% in soft subgrades.

- Applications: Forest roads, slope stabilization, erosion control.

2.3 Differences of Geogrid vs Geocell – Infill Material Compatibility

The type of infill material used with geogrids and geocells affects project cost and performance.

Geogrid: Restricted Infill

Geogrids require well-graded, high-quality aggregates (e.g., crushed stone with 5–20 mm diameter) to ensure interlocking and stability. The two-dimensional structure limits infill confinement, making poorly graded or fine-grained soils (e.g., sand, silt) prone to displacement under load. This increases material costs by 10–20%, as high-quality aggregates cost $10–$30/ton (BaseCore, 2024). For example, uniaxial geogrids used in retaining walls require angular gravel to maximize shear strength.

Infill Constraints:

- Suitable Materials: Crushed stone, gravel (5–20 mm).

- Unsuitable Materials: Sand, silt, recycled materials.

- Cost Impact: Higher infill costs ($0.10–$0.30/m² additional).

Geocell: Versatile Infill

Geocells support a wide range of infill materials, including locally available soils, quarry waste, recycled asphalt, and poorly graded aggregates. The three-dimensional confinement stabilizes infill, allowing the use of low-cost materials like sand or native soils, reducing material costs by 20–40% (Geosynthetic Institute, 2023). For instance, Vodaland’s 4-inch geocells can be filled with soil, gravel, or concrete, offering flexibility for erosion control or road stabilization.

Infill Flexibility:

- Suitable Materials: Soil, sand, gravel, concrete, recycled materials.

- Cost Impact: Lower infill costs ($0.05–$0.15/m²).

- Environmental Benefit: Reduces landfill waste by utilizing recycled materials.

2.4 Differences of Geogrid vs Geocell – Flexibility and Installation

Flexibility and ease of installation influence project timelines and labor costs.

Geogrid: High Flexibility

Geogrids’ planar design makes them highly flexible, conforming to irregular terrains with minimal site preparation. They are supplied in rolls (1–6 m wide) and unrolled over the subgrade, requiring compaction and infill placement. Installation is straightforward, with labor costs of $0.10–$0.30/m², but soft subgrades may require multiple layers, increasing installation time by 10–20%.

Installation Steps:

- Prepare subgrade (remove debris, compact to 95% Proctor density).

- Unroll geogrid, ensuring 30 cm overlap at joints.

- Place and compact infill (150–300 mm thick).

- Verify alignment and tension.

Advantages:

- Fast installation (500–1,000 m²/day).

- Suitable for uneven surfaces.

Geocell: Moderate Flexibility

Geocells are less flexible due to their three-dimensional structure, requiring precise site preparation to ensure proper expansion. Supplied in collapsed panels, geocells are stretched into a honeycomb pattern, anchored with rebar J-hooks, and filled with infill. Installation is more labor-intensive, with costs of $0.20–$0.50/m², but their rigidity reduces long-term maintenance by 15–20% (BPM Geosynthetics, 2024).

Installation Steps:

- Prepare subgrade (grade to ±2 cm tolerance).

- Expand geocell panels, anchor with J-hooks (1–2/m²).

- Fill cells with infill, compact in 50 mm lifts.

- Verify cell alignment and infill density.

Advantages:

- High stability on soft subgrades.

- Reduced pavement thickness, saving 20–30% on aggregate.

2.5 Differences of Geogrid vs Geocell – Applications and Suitability

Geogrids and geocells serve overlapping but distinct applications based on their structural properties.

Geogrid Applications

Geogrids are ideal for projects requiring tensile reinforcement and moderate load distribution:

- Road and Railway Bases: Biaxial geogrids reinforce subgrades with CBR > 4, reducing cracking by 15–25% (BaseCore, 2024).

- Retaining Walls: Uniaxial geogrids provide tensile strength (50–200 kN/m), stabilizing soil behind walls.

- Shallow Foundations: Increase bearing capacity by 10–20% in firm soils.

- Slope Reinforcement: Prevent soil slippage on slopes < 45°.

Best Suited For:

- Firm subgrades (CBR > 4).

- Projects prioritizing flexibility and cost ($0.50–$2.00/m²).

Geocell Applications

Geocells excel in projects requiring confinement, erosion control, and high load support:

- Soft Subgrade Stabilization: Ideal for forest roads or mining access roads with CBR < 2, reducing settlement by 30–50%.

- Slope Protection: Prevent erosion on slopes up to 60°, supporting vegetation growth.

- Erosion Control: Perforated geocells reduce runoff velocity by 20–30% (Ocean Geosynthetics, 2021).

- Retaining Walls: Distribute loads behind walls, reducing soil sliding by 25%.

Best Suited For:

- Soft subgrades (CBR < 2).

- Projects prioritizing durability and infill versatility.

2.6 Differences of Geogrid vs Geocell – Cost Considerations

Cost is a critical factor in geosynthetic selection, encompassing material, installation, and long-term maintenance.

Geogrid Costs

Geogrids are generally cheaper upfront, with material costs of $0.50–$2.00/m². However, their reliance on high-quality infill and potential need for multiple layers can increase total costs by 20–30% in soft subgrades. Maintenance costs are higher due to infill displacement, averaging $0.05–$0.15/m² annually (BaseCore, 2024).

Cost Breakdown:

- Material: $0.50–$2.00/m²

- Installation: $0.10–$0.30/m²

- Maintenance: $0.05–$0.15/m²/year

- Total (10 years): $1.00–$3.50/m²

Geocell Costs

Geocells have higher material costs ($1.00–$3.00/m²) due to their complex manufacturing process. However, their ability to use low-cost infill and reduced pavement thickness lowers overall project costs by 20–40%. Lower maintenance needs (due to confinement) result in annual costs of $0.02–$0.10/m² (BPM Geosynthetics, 2024).

Cost Breakdown:

- Material: $1.00–$3.00/m²

- Installation: $0.20–$0.50/m²

- Maintenance: $0.02–$0.10/m²/year

- Total (10 years): $1.40–$4.00/m²

3. How to Choose Between Geogrid and Geocell

Selecting the right geosynthetic depends on project requirements, site conditions, and budget. Consider the following factors:

3.1 Subgrade Conditions

- Firm Subgrades (CBR > 4): Geogrids are cost-effective, providing sufficient reinforcement with minimal material.

- Soft Subgrades (CBR < 2): Geocells are superior, offering confinement and reducing settlement by 30–50%.

3.2 Project Type

- Roads and Foundations: Geogrids suit paved roads with firm subgrades, while geocells are ideal for unpaved roads or soft soils.

- Slopes and Erosion Control: Geocells excel in steep slopes (>45°) and vegetated projects, while geogrids are better for moderate slopes (<45°).

3.3 Budget and Long-Term Costs

- Short-Term Budget: Geogrids are cheaper upfront ($0.50–$2.00/m²).

- Long-Term Savings: Geocells reduce maintenance and infill costs, saving 20–40% over 10 years.

3.4 Environmental Impact

Geocells support sustainable practices by using recycled or native infill, reducing landfill waste by 15–20% (Geosynthetic Institute, 2023). Geogrids, requiring high-quality aggregates, have a higher environmental footprint.

4. Conclusion

Geogrids and geocells are vital geosynthetic materials, each offering unique advantages for soil stabilization and reinforcement. Geogrids, with their two-dimensional grid structure, provide flexible tensile reinforcement for firm subgrades, costing $0.50–$2.00/m² and excelling in road bases and retaining walls. Geocells, with their three-dimensional honeycomb design, offer superior confinement and load distribution for soft subgrades, costing $1.00–$3.00/m² and ideal for slope protection and erosion control. By understanding their differences—structural design, load-bearing capacity, infill compatibility, flexibility, and applications—you can make informed decisions for your project. For tailored solutions, contact BPM Geosynthetics to ensure optimal performance and cost-efficiency.