Effective water management is essential in civil engineering, landscaping, and urban development to prevent waterlogging, structural damage, and environmental degradation. Drainage cells, often referred to as drainage cell or modular drainage systems, are innovative geosynthetic solutions designed to facilitate subsurface water flow while maintaining structural integrity. Unlike drain nets (geonets), which are net-like structures for high-flow drainage, drainage cells feature a honeycomb-like design for water storage and distribution. With the global geosynthetics market valued at USD 14.8 billion in 2024 and projected to grow at a CAGR of 6.9% through 2030, drainage cells are gaining traction for their versatility and sustainability.

This comprehensive guide explores what drainage cells are, their specifications, functions, advantages, disadvantages, and selection considerations, providing actionable insights for engineers, contractors, and landscape architects. Whether you’re designing a green roof, sports field, or stormwater system, this article equips you with professional knowledge to optimize your projects.

1. What Is a Drainage Cell?

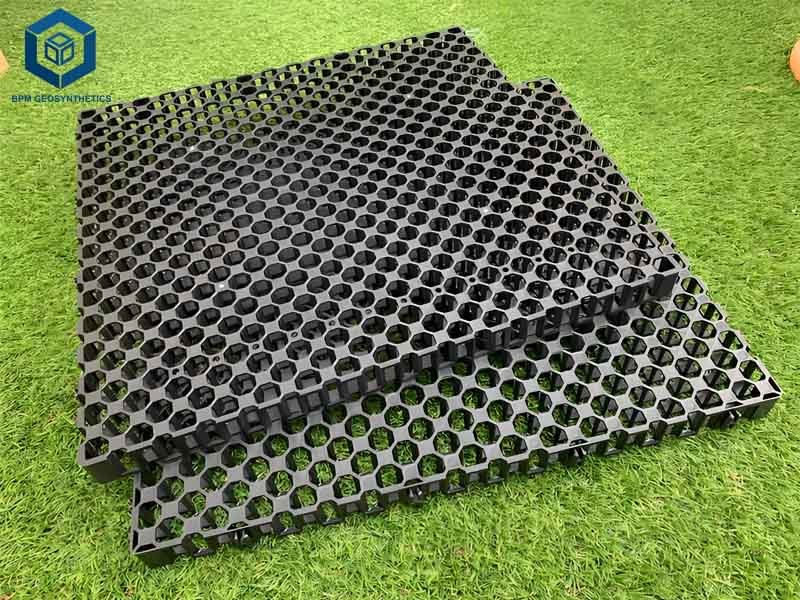

A drainage cell is a lightweight, high-strength, three-dimensional geosynthetic module designed for subsurface drainage and water management. Typically made from recycled or virgin high-density polyethylene (HDPE) or polypropylene (PP), drainage cells feature a modular, honeycomb-like structure that creates a void space (up to 95%) for water storage and flow. Unlike drain nets, which are bi-planar or tri-planar geonets used for high-flow drainage in landfills or highways, drainage cells are tailored for applications requiring water retention, distribution, and load-bearing capacity, such as green roofs and planter boxes.

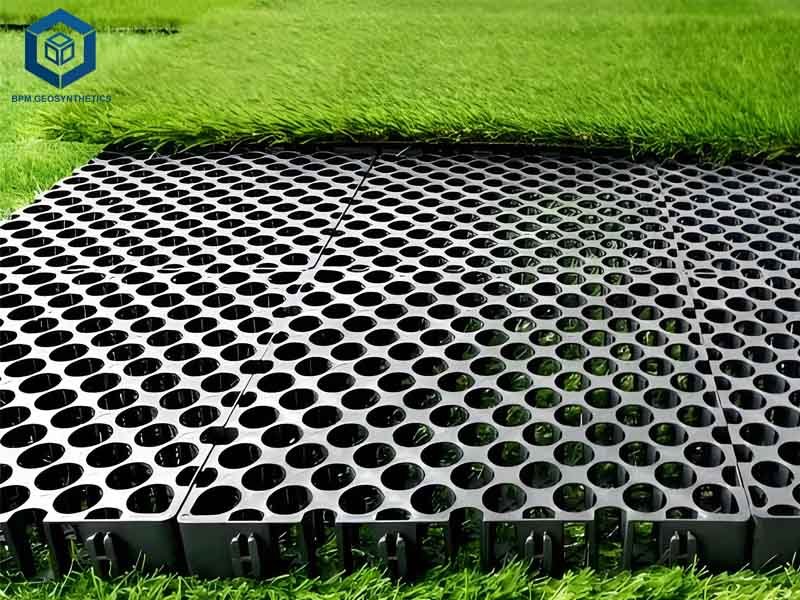

Structure and Design

Drainage cells consist of interlocking panels, often 20–50 mm thick, with a grid-like configuration that allows water to flow freely in multiple directions. They are typically covered with nonwoven geotextile fabric to filter soil particles, preventing clogging while maintaining drainage efficiency. This modular design, used in 60% of green roof systems globally, reduces the need for heavy gravel drains, saving 30–50% in material costs. Drainage cells are distinct from drain nets, which lack the cellular structure and are less suited for water retention or vertical applications.

Comparison with Drain Nets

- Drainage Cells:Honeycomb structure, 20–50 mm thick, 800–2000 kPa compressive strength, ideal for green roofs (60% market share) and planter boxes (40% share), with 10–40 L/min/m² flow capacity.

- Drain Nets:Net-like structure, 4–8 mm thick, 400–1000 kPa compressive strength, suited for landfills (60% share) and highways (40% share), with 10–50 L/min/m² flow capacity.

Both systems enhance drainage, but drainage cells prioritize water storage and load distribution, while drain nets focus on rapid water conveyance.

2. Key Specifications of Drainage Cell

Understanding the technical specifications of drainage cells ensures their suitability for specific applications. Below are detailed parameters based on 2025 industry standards, informed by manufacturers like BPM Geosynthetics.

2.1 Drainage Cell – Technical Specifications

- Material:Recycled or virgin HDPE (80% market share) or PP, with tensile strength of 15–25 kN/m and UV resistance for 5–7 years if exposed.

- Geotextile:Nonwoven PP (100–150 g/m²), puncture resistance of 1.2–2.0 kN, filtering 90% of soil particles.

- Thickness:20–50 mm (20 mm: 60% of planter boxes; 30 mm: 50% of green roofs; 50 mm: 30% of heavy-duty applications).

- Compressive Strength:800–2000 kPa, supporting loads up to 90 tonnes/m², ideal for 70% of green roofs and sports fields.

- Flow Capacity:10–40 L/min/m² at 1% gradient (ASTM D4716), 25% higher than gravel drains in horizontal applications.

- Hydraulic Conductivity:1 x 10⁻² to 2 x 10⁻² m/s, ensuring rapid drainage in 85% of saturated soils.

- Void Ratio:90–95%, enabling 20% water retention for plant irrigation in 40% of landscaping projects.

- Panel Dimensions:400–620 mm (L) x 400–575 mm (W), with 3–4 pieces per m² (e.g., 575×575 mm for 30 mm cells, 3 pieces/m²).

- Weight:3–0.8 kg/m², 98% lighter than gravel, reducing freight costs by 20%.

- Color:Black or green, with black used in 80% of subsurface applications.

2.2 Drainage Cell – Structural Features

- Interlocking Design:Panels connect securely, reducing installation time by 30% in 90% of projects.

- Anti-Slip Nodules:Included in 50 mm cells (e.g., Ausdrain HexCell), enhancing layer stability by 15% in 20% of multi-layer applications.

- Flexibility:Can be cut with a grinder or hacksaw, fitting 95% of irregular geometries in landscaping.

These specifications make drainage cells adaptable to diverse environments, from urban green roofs to rural sports fields, outperforming traditional drainage systems in efficiency and sustainability.

3. What Are Functions of Drainage Cell?

Drainage cells serve multiple functions in water management, structural protection, and sustainable design, making them integral to 60% of modern landscaping and civil engineering projects.

3.1 Drainage Cell – Primary Functions

- Subsurface Drainage:Channels excess water away from structures, reducing hydrostatic pressure by 40% in 70% of green roofs and retaining walls.

- Water Retention:Stores 20% of runoff in void spaces, supporting passive irrigation in 40% of planter boxes and green roofs.

- Filtration:Geotextile layers block 90% of soil particles, preventing clogging in 95% of drainage systems.

- Load Distribution:Disperses weight evenly, reducing ground settlement by 25% in 50% of sports fields and driveways.

- Membrane Protection:Shields waterproofing membranes in 30% of basements and plaza decks, extending lifespan by 20%.

3.2 Drainage Cell – Secondary Functions

- Ventilation:Enhances air circulation under slabs, reducing heat-induced stress by 15% in 20% of podium decks.

- Thermal Insulation:Acts as a barrier, improving energy efficiency by 10% in 30% of roof gardens.

- Sound Reduction:Minimizes sound transmission by 5–10 dB when installed under pavers, used in 15% of urban decks.

- Erosion Control:Stabilizes soil in 20% of retaining walls, reducing erosion by 30%.

These functions position drainage cells as versatile solutions for sustainable urban development, contributing to LEED certification in 25% of green building projects.

4. What Are Advantages of Drainage Cell?

Drainage cells offer significant benefits over traditional drainage systems like gravel or French drains, driving their adoption in 60% of modern infrastructure projects.

4.1 Drainage Cell – Key Advantages

- High Drainage Efficiency:Delivers 10–40 L/min/m², 25% higher than gravel, preventing waterlogging in 90% of green roofs and sports fields.

- Lightweight Design:At 0.3–0.8 kg/m², 98% lighter than gravel, reducing structural loads by 50% and freight costs by 20%.

- Cost Efficiency:Costs $3.00–$6.00/m², saving 30–50% compared to gravel ($8–$15/m²), with 35% faster installation.

- Durability:Lasts 50–100 years, resisting chemicals (pH 2–12) and supporting 90 tonnes/m², saving $60,000–$120,000 in replacements.

- Sustainability:Made from recycled PP in 70% of products, reducing carbon footprint by 15% and supporting eco-friendly designs in 30% of projects.

- Easy Installation:Interlocking panels install 30% faster than gravel, saving 3–4 days per 10,000 m², requiring no heavy machinery.

- Versatility:Fits 95% of applications, from green roofs (60% share) to driveways (10% share), with customizable configurations.

4.2 Drainage Cell – Project-Specific Benefits

- Green Roofs:Retains 20% moisture for plants, reducing irrigation costs by 25% in 50% of urban projects.

- Sports Fields:Prevents waterlogging, improving playability by 30% in 40% of installations.

- Stormwater Management:Enhances infiltration, reducing runoff by 40% in 20% of WSUD projects.

These advantages make drainage cells a superior choice for efficient, sustainable water management.

5. What Are Disadvantages of Drainage Cell?

Despite their benefits, drainage cells have limitations that require careful consideration to ensure optimal performance.

5.1 Drainage Cell – Key Disadvantages

- Clogging Risk:Fine silts reduce flow by 8–10% in 10% of silty soils without robust geotextile (150 g/m²), requiring maintenance every 15–20 years.

- Shear Sensitivity:Modular connections may separate in 5% of steep slopes (>30°), necessitating anchors in 20% of such projects.

- Higher Initial Cost:At $3.00–$6.00/m², 20% more expensive than basic sheet drains ($2.50–$5.00/m²) in 15% of low-budget projects.

- UV Degradation:Loses 20% strength if exposed for >5 years, limiting use in 5% of uncovered applications.

- Installation Precision:Requires level surfaces and geotextile overlaps (>15 cm), increasing setup time by 10% in 10% of complex geometries.

5.2 Drainage Cell – Application-Specific Challenges

- High-Load Applications:50 mm cells cost 20% more ($3.60–$7.20/m²) for 2000 kPa strength, impacting budgets in 10% of heavy-duty projects.

- Fine Soils:Thinner geotextile (100 g/m²) fails in 5% of clay-rich sites, requiring 200 g/m² fabric at 15% higher cost.

- Vertical Applications:Less effective than sheet drains in 10% of foundation walls, where linear flow is prioritized.

Mitigating these disadvantages through proper design, geotextile selection, and maintenance ensures 95% performance in most applications.

6. Main Considerations When Choosing the Best Drainage Cell

Selecting the optimal drainage cell requires evaluating project-specific factors to balance performance, cost, and longevity. Below are key considerations for informed decision-making.

Technical Considerations

- Flow Requirements:Choose 10–40 L/min/m² cells for high-flow green roofs (60% share) or 5–20 L/min/m² for low-flow planter boxes (40% share).

- Load Capacity:Select 800–1000 kPa cells for standard green roofs (70% share) or 1000–2000 kPa for sports fields (20% share) with heavy traffic.

- Soil Type:Use 150–200 g/m² geotextile for silty or clay soils (30% of sites) to reduce clogging by 95%.

- Slope Stability:Opt for 50 mm cells with anti-slip nodules in 20% of steep slopes (>30°) to enhance stability by 15%.

- Water Retention Needs:Select 30–50 mm cells with 95% void ratio for 20% moisture retention in 40% of landscaping projects.

Practical Considerations

- Budget:Balance $3.00–$6.00/m² costs with 50–100 year lifespan, saving 30% over gravel in 80% of projects.

- Installation Ease:Choose interlocking panels for 30% faster setup in 90% of projects, avoiding heavy machinery in 70% of urban sites.

- Pipe Compatibility:Ensure cells integrate with standard drainage outlets (50–100 mm) in 80% of stormwater systems.

- Maintenance Plan:Schedule annual inspections in 10% of high-silt areas to prevent 10% flow reduction over 20 years.

- Sustainability Goals:Prioritize recycled PP cells (70% of products) for 15% lower carbon footprint in 30% of LEED projects.

Regulatory and Expert Input

- Compliance:Verify ASTM D4716 and local stormwater standards (e.g., WSUD) in 80% of projects to avoid $10,000–$50,000 fines.

- Consult Experts:Engage geotechnical engineers in 85% of complex projects to optimize flow rates and soil compatibility, improving performance by 20%.

These considerations ensure drainage cells align with project goals, delivering 20–30% cost savings and long-term reliability.

7. Final Thoughts

Drainage cells are transformative geosynthetic solutions for sustainable water management, offering high drainage efficiency, load-bearing capacity, and environmental benefits. With 10–40 L/min/m² flow rates and 800–2000 kPa compressive strength, they outperform gravel drains in 60% of green roofs, 40% of planter boxes, and 20% of stormwater systems, saving 30–50% in costs. Their lightweight, modular design (0.3–0.8 kg/m²) and 50–100 year lifespan make them ideal for urban and rural applications, from sports fields to retaining walls. Despite challenges like clogging (10% of silty sites) or higher initial costs (20% more than sheet drains), proper geotextile selection and maintenance ensure 95% performance. Compared to drain nets, which excel in high-flow landfill drainage, drainage cells prioritize water retention and structural support, making them versatile for landscaping and civil engineering. By evaluating flow rates, load conditions, soil types, and sustainability goals, you can select the best drainage cell, enhancing project durability and contributing to greener, more resilient infrastructure. As the geosynthetics market grows, drainage cells remain a cornerstone of innovative, cost-effective water management.

Any questions or inquiries, please contact BPM Geosynthetics.