Geosynthetic construction material is the geotechnical products manufactured from polymeric materials (the synthetic) used as part of a civil engineering project or system. There are few developments that have had such a rapid growth and strong influence on so many aspects of civil engineering practice as geosynthetic construction material. As the leading geosynthetics manufacturers, wholesalers and suppliers, The BPM had been dedicated to supplying one stop geosynthetics products and services to worldwide customers since its foundation in 2007. We have over 120 professional staffs and 16,000 square meters manufacturing factory equipped with state of the art production lines. Our main innovative, high quality geosynthetics products include geomembranes, geotextiles, geocells, geosynthetic clay liners (GCLs), drainage boards, geogrids, etc. All BPM brand geosynthetic construction material had been certificated by the ISO9001, ISO14001, Soncap, SASO and BV certificates and passed the test of SGS and Intertek etc.

Definitions and Types of Geosynthetic Construction Material

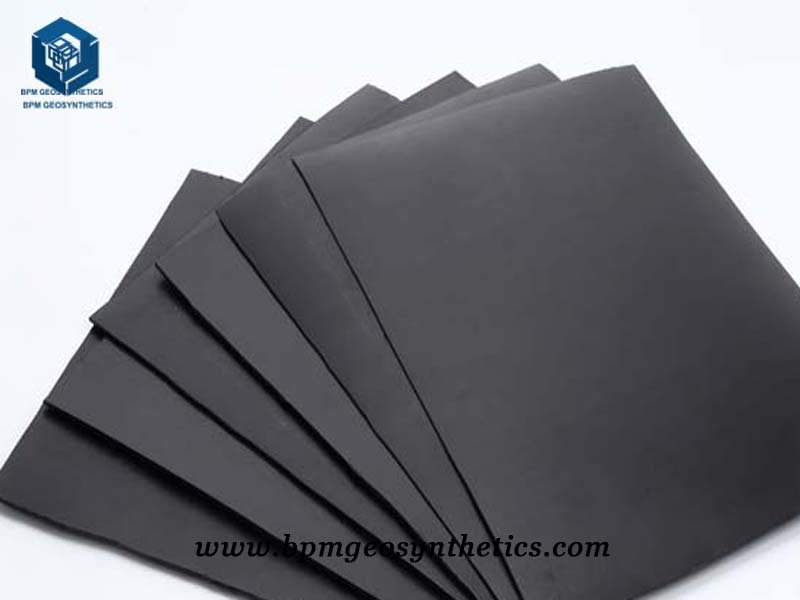

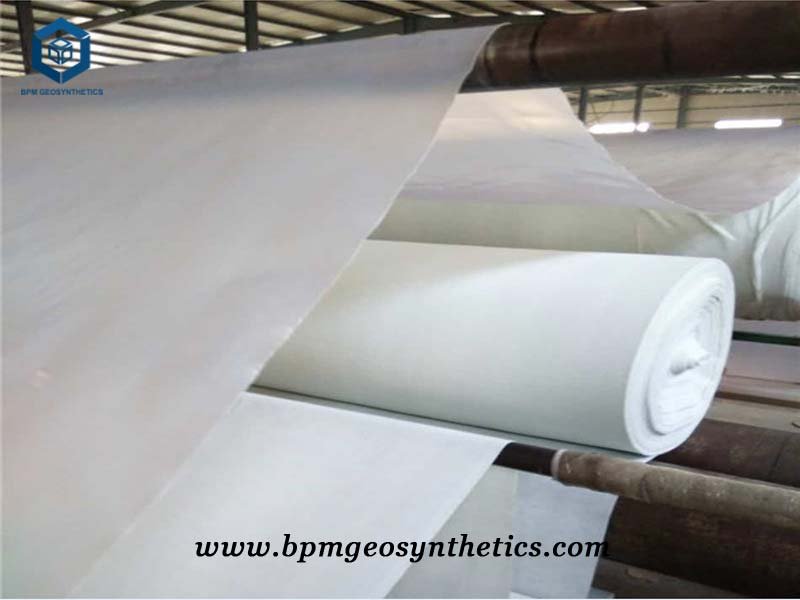

ASTM has defined the geosynthetic construction material as a planar product manufactured from a polymeric material used with soil, rock, earth, or other geotechnical-related material as an integral part of a civil engineering project, structure, or system. A geotextile is a permeable geosynthetic made of textile materials. Geogrids are primarily used for reinforcement; they are formed by a regular network of tensile elements with apertures of sufficient size to interlock with surrounding fill material. Geomembranes are lowper meability geosynthetics used as fluid barriers. Geotextiles and related products such as nets and grids can be combined with geomembranes and other synthetics to take advantage of the best attributes of each component. These products are called geocomposites, and they may be composites of geotextile-geonets, geotextile-geogrids, geomembrane-geonets, geotextile-polymeric cores, and even threedimensional polymeric cell structures. There is almost no limit to the variety of geocomposites that are possible and useful.

Types and Manufacture of Geosynthetic Construction Material

Most geosynthetic construction material is made from synthetic polymers such as polypropylene, polyester, polyethylene, polyamide, PVC, etc. These geotechnical materials are highly resistant to biological and chemical degradation. In manufacturing geotextiles, elements such as fibers or yarns are combined into planar textile structures. The fibers can be continuous filaments, which are very long thin strands of a polymer, or staple fibers, which are short filaments, typically 20 to 100 mm long. The fibers may also be produced by slitting an extruded plastic sheet or film to form thin flat tapes. In both filaments and slit films, the extrusion or drawing process elongates the polymers in the direction of the draw and increases the fiber strength. Geotextile type is determined by the method used to combine the filaments or tapes into the planar textile structure. The vast majority of geotextiles are either woven or nonwoven. Woven geotextiles are made of monofilament, multifilament, or fibrillated yarns, or of slit films and tapes. Although the weaving process is very old, nonwoven textile manufacture is a modem industrial development. Synthetic polymer fibers or filaments are continuously extruded and spun, blown or otherwise laid onto a moving belt. Then the mass of filaments or fibers are either needle punched, in which the filaments are mechanically entangled by a series of small needles, or heat bonded, in which the fibers are welded together by heat and/or pressure at their points of contact in the nonwoven mass. Flexible geogrids are made of polyester yarns joined at the crossover points by knitting or weaving, and coated with a polymer.

Identification of Geosynthetic Construction Material

Geosynthetic construction material is generically identified by: polymer; type of fiber or yarn, if appropriate; type of geosynthetic; mass per unit area or thickness, if appropriate; and any additional information or physical properties necessary to describe the material.

Geosynthetic construction material applications are usually defined by their primary, or principal, function. In a number of applications, in addition to the primary function, geosynthetics usually perform one or more secondary functions. It is important to consider both the primary and secondary functions in the design computations and specifications. More than 150 separate applications of geosynthetics have been identified (Holtz et al., 1997; Koerner, 1998). A few examples follow: Geotextile filters replace graded granular filters in trench drains to prevent soils from migrating into drainage aggregate or pipes. They are also used as filters below riprap and other armor materials in coastal and river bank protection systems. Geotextiles and geocomposites can also be used as drains, by allowing water to drain from or through soils of lower permeability. Examples include pavement edge drains, slope interceptor drains, and abutments and retaining wall drains. Geotextiles are often used as separators to prevent fine-grained subgrade soils from being pumped into permeable, granular road bases and to prevent road base materials from penetrating into the underlying soft subgrade. Separators maintain the design thickness and roadway integrity. Geogrid and geotextile reinforcement enables embankments to be constructed over very soft foundations. They are also used to construct stable slopes at much steeper angles than would otherwise be possible. Polymeric reinforced backfills for retaining walls and abutments was mentioned in the Introduction. Geomembranes, thin-film geotextile composites, geosynthetic-clay liners, and field-coated geotextiles are used as fluid barriers to impede the flow of a liquid or gas from one location to another. This geosynthetic function has application in asphalt pavement overlays, encapsulation of swelling soils, and waste containment.

Geosynthetic Construction Material for Soil Reinforcement

The three primary applications soil reinforcement using geosynthetics are

- Reinforcing the base of embankments constructed on very soft foundations

- Increasing the stability and steepness of slopes

- Reducing the earth pressures behind retaining walls and abutments.

In the first two applications, geosynthetics permit construction that otherwise would be cost prohibitive or technically not feasible. In the case of retaining walls, significant cost savings are possible in comparison with conventional retaining wall construction. Other reinforcement and stabilization applications in which geosynthetics have also proven to be very effective include roads and railroads, large area stabilization, and natural slope reinforcement, but these applications are not discussed in this paper.

Geosynthetic Construction Material Properties

Geosynthetic properties Properties are required for design (stability), constructability, and durability. Allowable tensile strength and soil-geosynthetic friction are required for stability design, and similar to reinforced slopes, a partial factor or reduction factor approach is common. The ultimate wide width strength is reduced to account for uncertainties in creep strength, chemical and biological degradation effects, installation damage, and joints and connections.

Backfill for geosynthetic reinforced walls should be free draining if at all possible. If not, then adequate drainage of infiltrating surface or groundwater must be provided. This is important for stability considerations because drainage outward through the wall face may not be adequate. Soil properties required include gradation, percent fines, chemical composition, compaction, unit weight, and shear strength. To insure stability, appropriate consideration of the foundation and overall slope stability at the site is also important.

About BPM

BPM had been specializing in delivering one stop geosynthetics products and solutions to worldwide customers since its foundation in 2007. BPM had provided many types of effective and state of the art geomembrane, geotextile, geocell, geosynthetic clay liners (GCLs), drainage board, geogrid to over 36 countries.

BPM is not only manufacturing best quality geosynthetics products but also providing professional design and installation service. OEM, and ODM are also available. If you have any questions or inquiries, please fill and submit the following form, we will reply as soon as possible.